A method for eliminating overcutting of non-circular tooth sector deformation and modification

A toothed sector, non-circular technology, which is applied in the field of non-circular toothed sector deformation and overcut elimination, can solve the problems of not reaching the theoretical design value, low production efficiency, small drum volume, etc., so as to improve production efficiency. , The effect of eliminating tooth profile overcut and simplifying the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

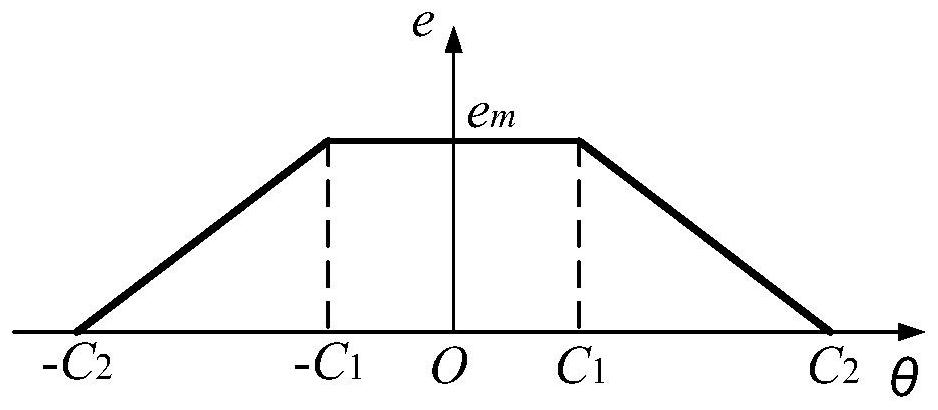

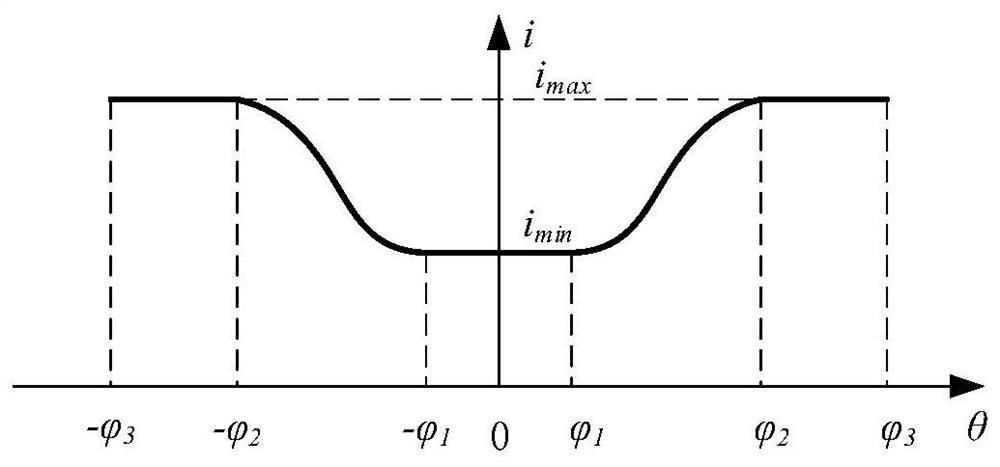

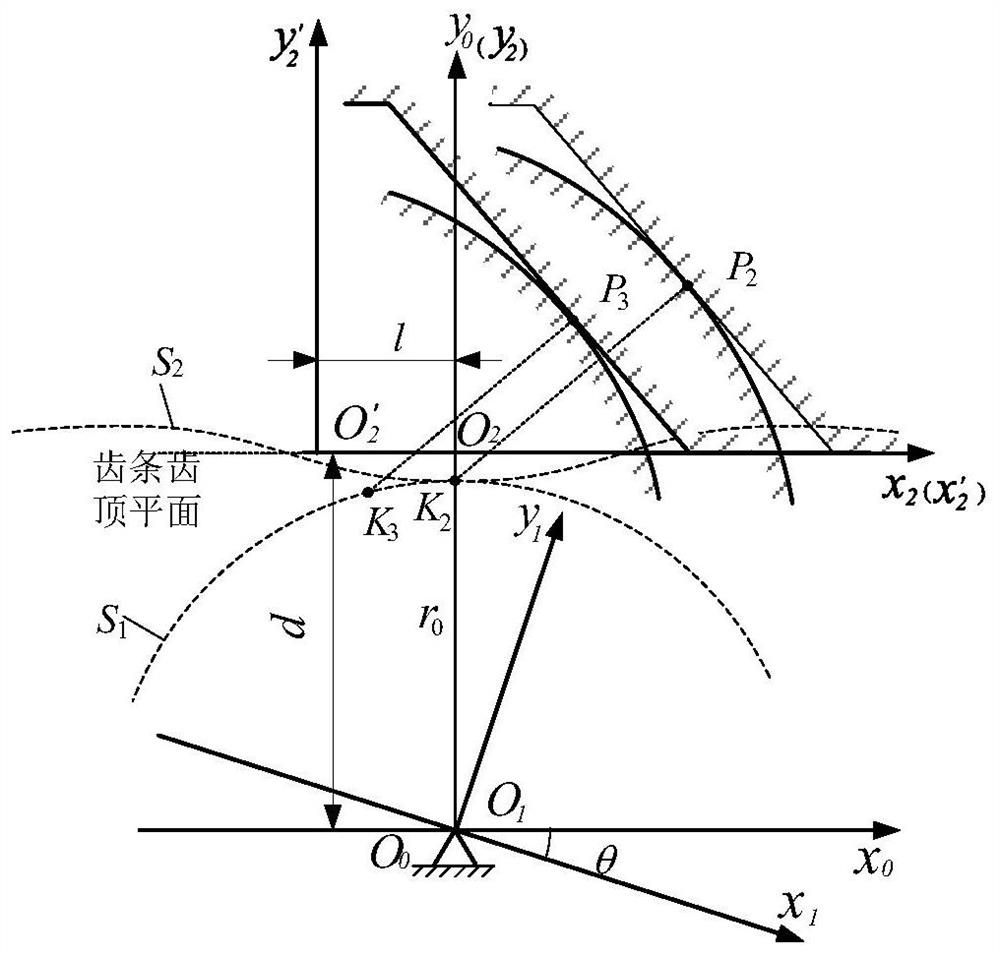

[0110] See the rack cutter in this embodiment Figure 7 Its parameters are shown in Table 1. In this embodiment, the tooth profile modification parameters of the tooth sector are shown in Table 2, the cosine function transmission ratio parameters are shown in Table 3, and the cosine variable ratio non-circular tooth sector workpiece parameters are shown in Table 4.

[0111] Table 1 Rack tool parameters

[0112]

[0113]

[0114] Table 2 Tooth profile modification parameters of tooth sector

[0115]

[0116] Table 3 Gear ratio parameters

[0117]

[0118] Table 4 Workpiece parameters

[0119]

[0120] Calculate the theoretical tooth profile equation and establish the theoretical tooth profile model of displacement modification, see Figure 8 shown. Use this non-circular tooth sector to reverse the rack tool, see the reverse process Figure 9 shown. For the reversed rack tool tooth profile, see Figure 10 As shown, reverse the concave tooth profile of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com