Cable connection crimping machine and crimping method

A cable splicing and crimping machine technology, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of cable damage at the splicing part, increase splicing resistance, cable depression, etc., to improve accuracy and stability, reduce sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

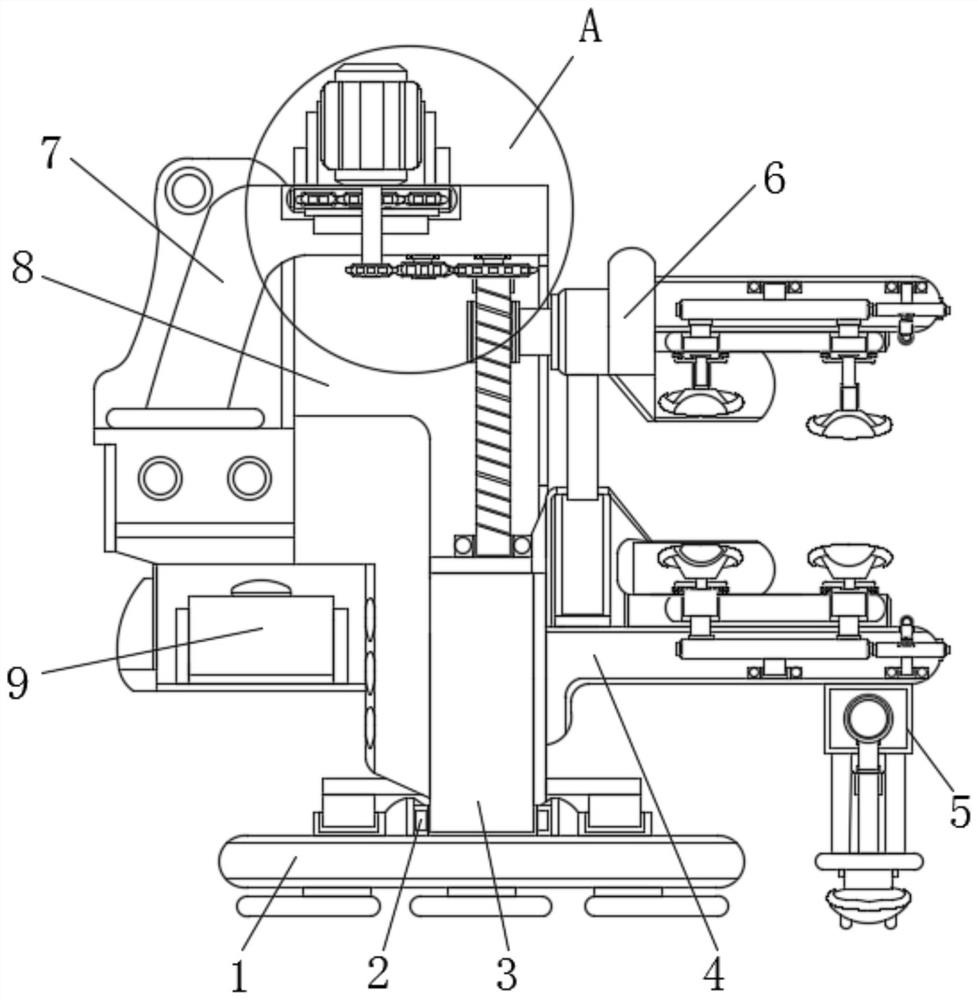

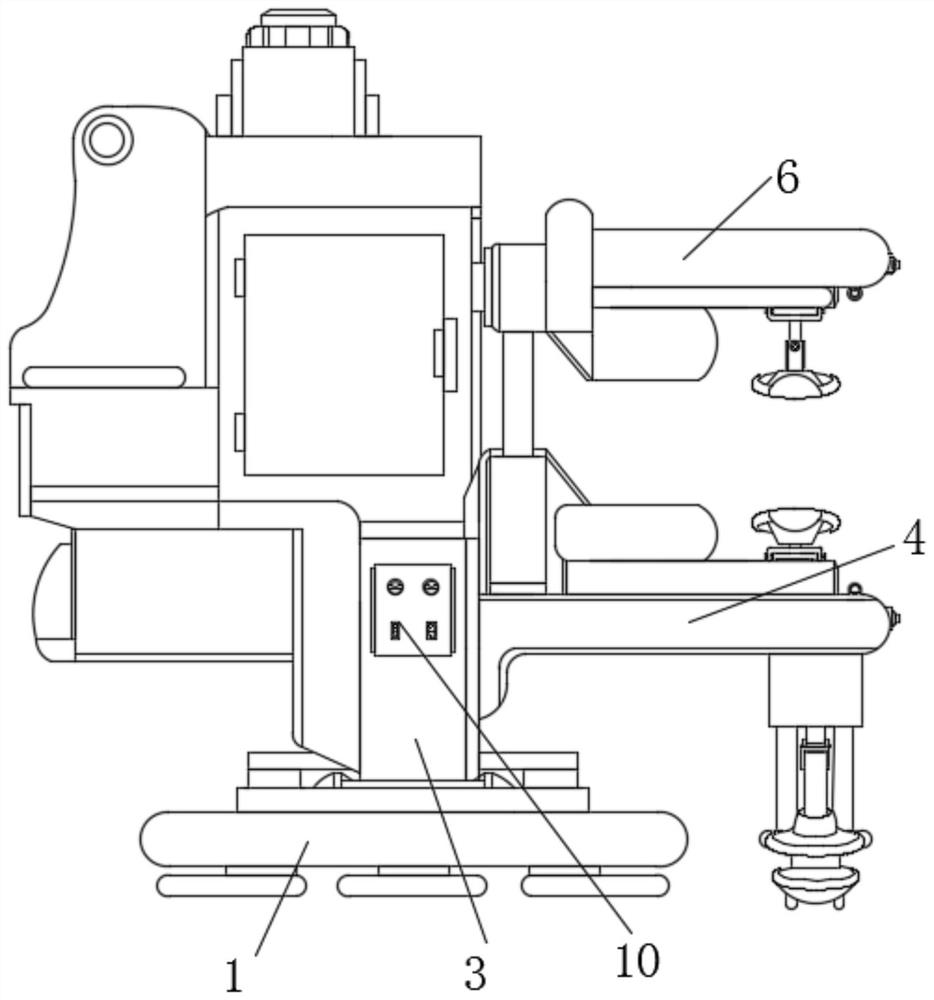

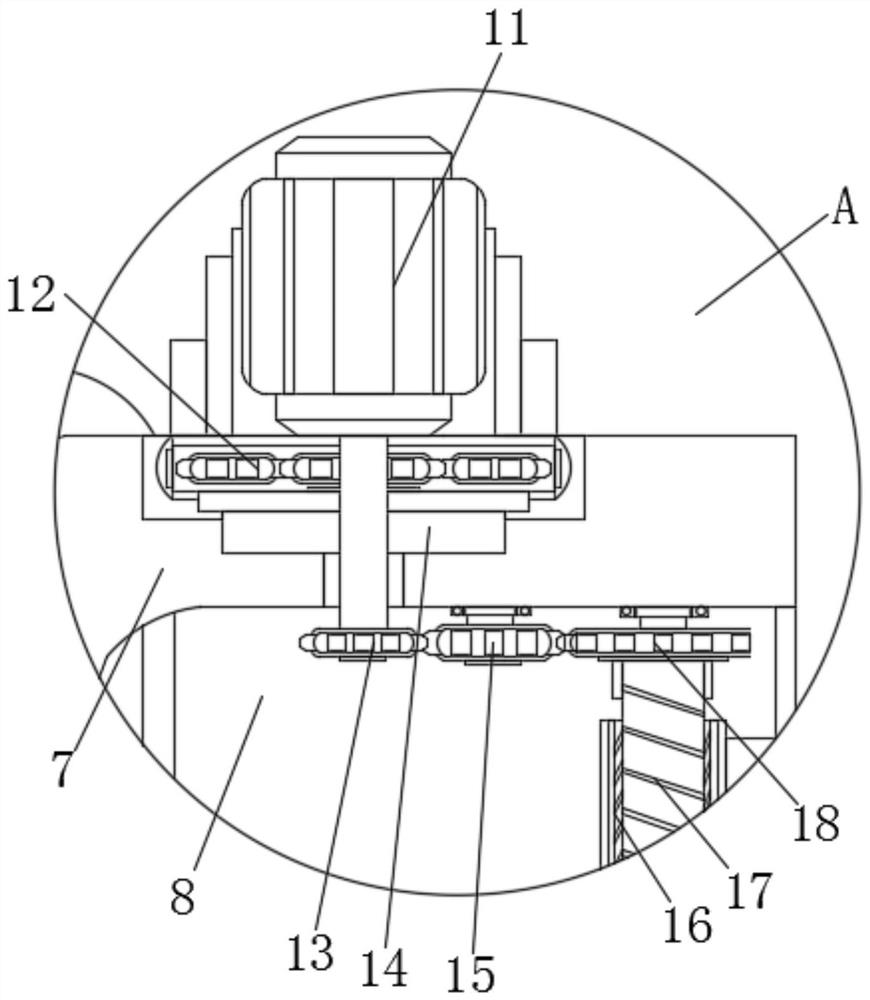

[0035] see Figure 1-8 , the present invention provides a technical solution: a cable splicing crimping machine, including a base 1, a turntable 2 is provided at the middle of the top of the base 1, a mounting seat 3 is provided on the inner side of the turntable 2, and a body 8 is provided on the top of the mounting seat 3 One side of the body 8 is provided with a connecting frame 7, the top of one side of the base 1 is provided with a lower crimping table 4, one side of the top of the body 8 is provided with a low-voltage DC motor 11, and one side of the top of the connecting frame 7 is provided with a The output end of the low-voltage DC motor 11 is connected to the reduction box 12, the bottom of the low-voltage DC motor 11 is provided with a connecting shaft 14, the bottom outside the connecting shaft 14 is provided with a driving gear 13, and the middle position of the top of the body 8 is sleeved with a The driven gear 15 with the driving gear 13 meshing with each other...

Embodiment 2

[0042] see Figure 1-8 , the present invention provides a technical solution: a cable splicing crimping machine, including a base 1, a turntable 2 is provided at the middle of the top of the base 1, a mounting seat 3 is provided on the inner side of the turntable 2, and a body 8 is provided on the top of the mounting seat 3 One side of the body 8 is provided with a connecting frame 7, the top of one side of the base 1 is provided with a lower crimping table 4, one side of the top of the body 8 is provided with a low-voltage DC motor 11, and one side of the top of the connecting frame 7 is provided with a The output end of the low-voltage DC motor 11 is connected to the reduction box 12, the bottom of the low-voltage DC motor 11 is provided with a connecting shaft 14, the bottom outside the connecting shaft 14 is provided with a driving gear 13, and the middle position of the top of the body 8 is sleeved with a The driven gear 15 with the driving gear 13 meshing with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com