Chlorine dioxide disinfection method

A chlorine dioxide, disinfection device technology, applied in chemical instruments and methods, disinfection, mixing methods and other directions, can solve the problems that tableware cannot be cleaned and disinfected integrated operation, increase tableware cleaning cost, and tableware cleaning process is cumbersome, etc. Practicality and use time, ensuring the quality of disinfection, the effect of good disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

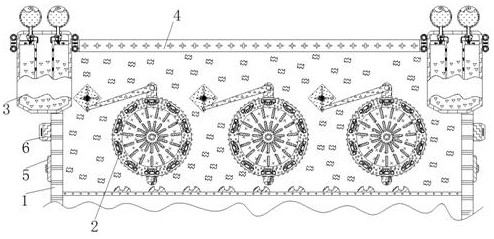

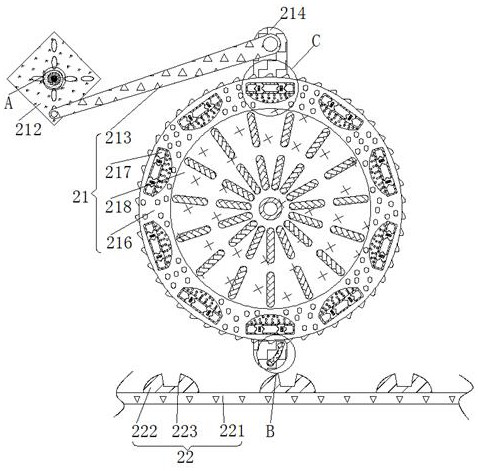

[0033] see Figure 3-6 , a chlorine dioxide disinfection device, comprising a shell 1, the inside of the shell 1 is movably connected with a disinfection mechanism 2, the disinfection mechanism 2 includes a processing assembly 21 for cleaning tableware, a fastening assembly 22 for supporting and positioning the tableware, and the processing assembly 21 is movable Connected to the inside of the shell 1 , the fastening assembly 22 is fixedly connected to the inside of the shell 1 .

[0034] The processing assembly 21 includes a motor 211, a rotating disk 212, a connecting rod 213, a swing rod 214, a push rod 215, a movable plate 216, a spray plate 217, and a friction plate 218. The motor 211 is fixedly connected to the inside of the housing 1, and the rotating disk 212 is fixedly connected to the motor. 211, the connecting rod 213 is movably connected to the outside of the turntable 212, the swing rod 214 is movably connected to the inside of the casing 1, the push rod 215 is fi...

Embodiment 2

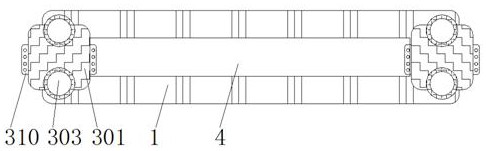

[0038] see figure 2 , 7 -9, a chlorine dioxide disinfection device, including a housing 1, a disinfection mechanism 2 is movably connected to the inside of the housing 1, and the disinfection mechanism 2 includes a processing assembly 21 for cleaning tableware, a fastening assembly 22 for supporting and positioning the tableware, and a processing assembly 21 is movably connected inside the shell 1 , and the fastening assembly 22 is fixedly connected inside the shell 1 .

[0039] A mixing mechanism 3 is movably connected to the outside of the shell 1, and the mixing mechanism 3 includes a tank body 301, a conduit 302, an air storage shell 303, an air bag 304, a sealing plate 305, a spring 306, an air outlet 307, a delivery pipe 308, a liquid outlet pipe 309, Electromagnetic pump 310, the tank body 301 is fixedly connected to the outside of the casing 1, the conduit 302 is fixedly connected to the inside of the tank body 301, the gas storage case 303 is fixedly connected to th...

Embodiment 3

[0042] see Figure 1-9 , a chlorine dioxide disinfection device, comprising a shell 1, the inside of the shell 1 is movably connected with a disinfection mechanism 2, the disinfection mechanism 2 includes a processing assembly 21 for cleaning tableware, a fastening assembly 22 for supporting and positioning the tableware, and the processing assembly 21 is movable Connected to the inside of the shell 1 , the fastening assembly 22 is fixedly connected to the inside of the shell 1 .

[0043] The processing assembly 21 includes a motor 211, a rotating disk 212, a connecting rod 213, a swing rod 214, a push rod 215, a movable plate 216, a spray plate 217, and a friction plate 218. The motor 211 is fixedly connected to the inside of the housing 1, and the rotating disk 212 is fixedly connected to the motor. 211, the connecting rod 213 is movably connected to the outside of the turntable 212, the swing rod 214 is movably connected to the inside of the casing 1, the push rod 215 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com