Disinfection material with nanometer zero-valent iron as main disinfection component and preparation method thereof

A nano-zero-valent iron and nano-particle technology, which is applied in botany equipment and methods, disinfectants, chemicals for biological control, etc., can solve the problems of weak disinfection ability of disinfectants and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

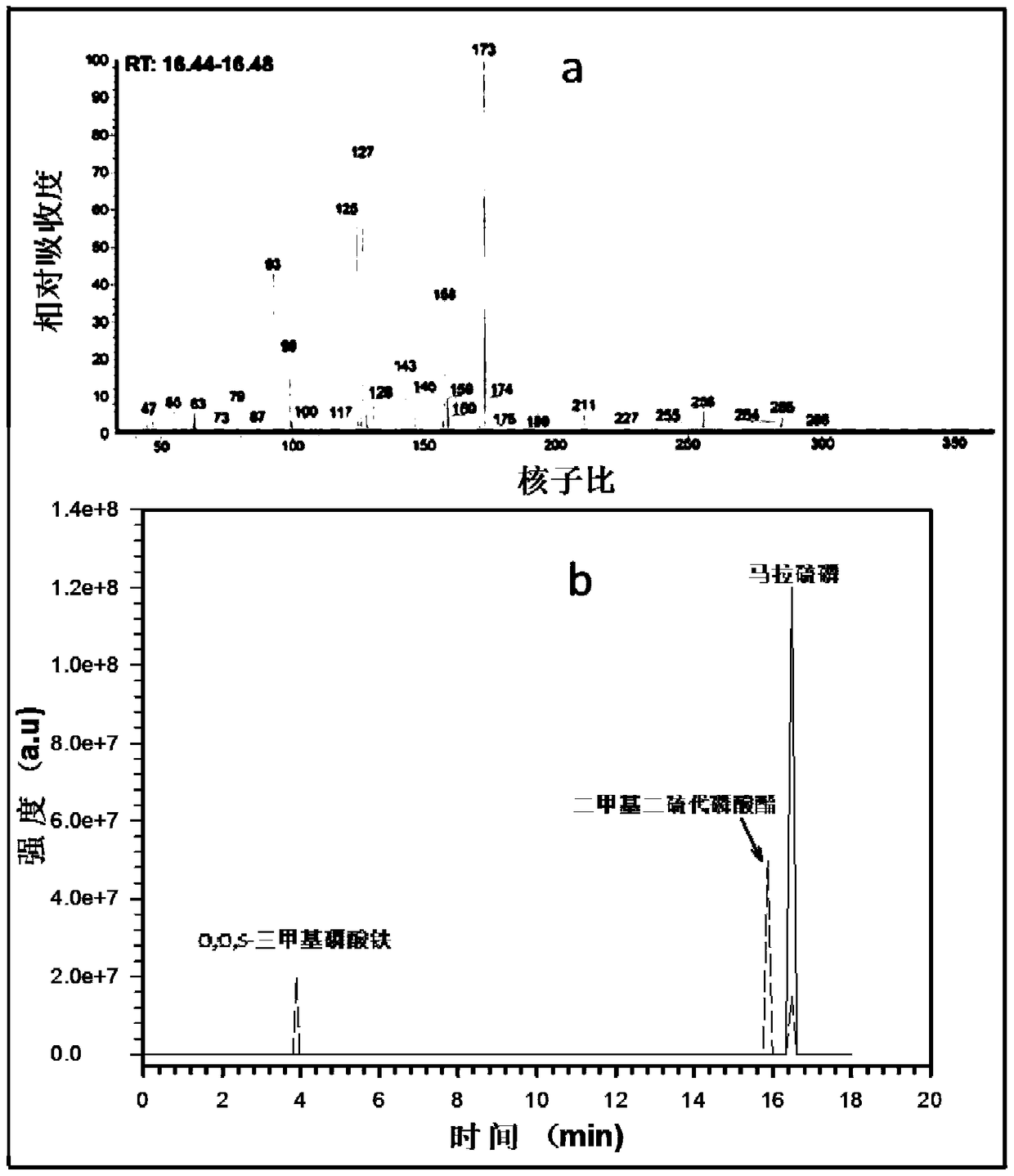

[0108] Example 1 Nano zero-valent Fe / Ni composite particles eliminate malathion in water

[0109] Put 300 mesh, analytically pure iron powder with a purity greater than 99.9% (Nanjing Welding Rod Iron Powder Factory), use 26mm stainless steel balls as grinding balls, and the ball-to-material ratio is 10:1 (weight ratio of grinding balls to iron powder), and put them into a new ball mill (XPEX8000M), at 250rpm, using intermittent (ball milling for 1 hour, intermittent 0.5 hour) ball milling for 10.5 hours, the nanoparticle tracking analysis (NTA) method measures the obtained iron grain size is about 140-300nm, that is, nano-scale iron pink. The above-mentioned nanoscale iron powder is immersed in the mixed solution of 0.2mol / L HCl and acetic acid through deoxidation treatment in the ratio of 1g:10mL. The volume ratio of hydrochloric acid and acetic acid in this mixed solution is 1:1 (the oxygen content is less than 0.5mg / L), at N 2 Under protection and accompanied by shaking...

Embodiment 2

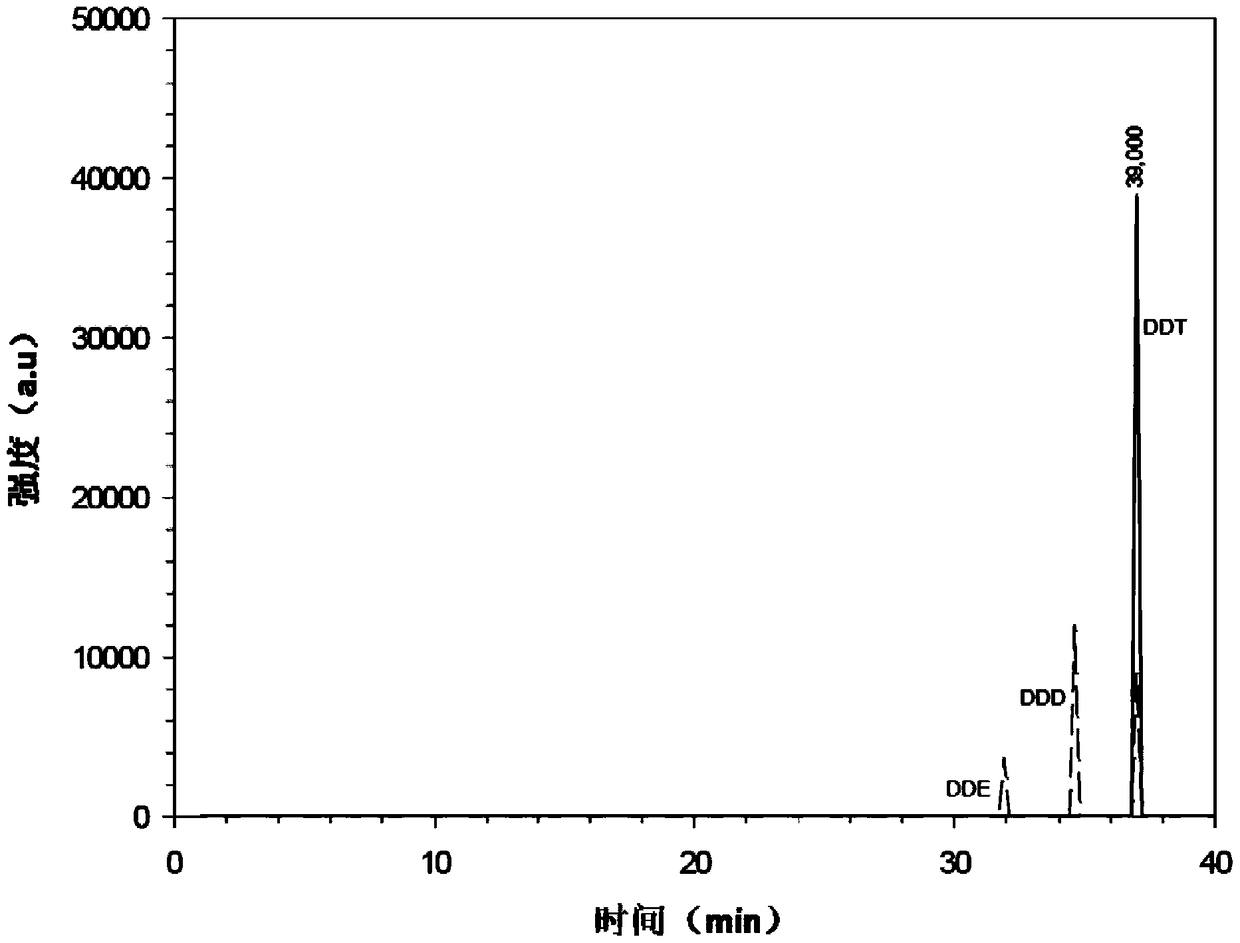

[0111] Example 2 Elimination of organochlorine pesticide DDT by using nanometer zero-valent Fe / Ag composite particles

[0112] Put 300 mesh, analytically pure iron powder with a purity greater than 99.9%, use 26mm stainless steel balls as grinding balls, and the ball-to-material ratio is 20:1, and put it into a planetary ball mill at 250rpm, using a batch type (ball milling for 1 hour, intermittent 0.5 hours) After ball milling for 7 hours, the obtained iron grain size is about 160-400nm as measured by nanoparticle tracking analysis (NTA), that is, nanoscale iron powder is obtained. The above-mentioned nanoscale iron powder is immersed in a deoxidized 0.1mol / L HCl and acetic acid solution (the volume ratio of hydrochloric acid and acetic acid is 1:1) in the ratio of 1g:20mL (oxygen content is less than 0.5mg / L), in N 2 Under protection and accompanied by shaking at a shaking speed of 400rpm for 8min, filter, wash with distilled water with an oxygen content of less than 0.5mg / ...

Embodiment 3

[0114] Example 3 Utilizes zero-valent Fe / Pd bimetallic particles to eliminate nitro compounds TNT in water

[0115] With 300 meshes, analytically pure iron powder with a purity greater than 99.9%, use 26mm stainless steel balls as grinding balls, and the ball-to-material ratio is 20:1, put them into a planetary ball mill, and use intermittent ball milling at 200rpm (ball milling for 1 hour, intermittent 0.5 hours) ) ball milled for 12 hours, and the diameter of the obtained nano-iron particles was measured to be about 120-268nm. The above-mentioned nanoscale iron powder is immersed in the deoxidized 0.5mol / L HCl and acetic acid solution in the ratio of 1g:5mL, and the volume ratio of hydrochloric acid and acetic acid in this mixed solution is 1:1 (the oxygen content is less than 0.5mg / L L), in N 2 Under protection and accompanied by shaking at a shaking speed of 400rpm for 5min, filter, rinse with distilled water with an oxygen content of less than 0.5mg / L to neutrality, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com