Rare earth metal alloy plate surface grinding equipment

A rare-earth metal and alloy plate technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of low efficiency, time-consuming and labor-intensive grinding of unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

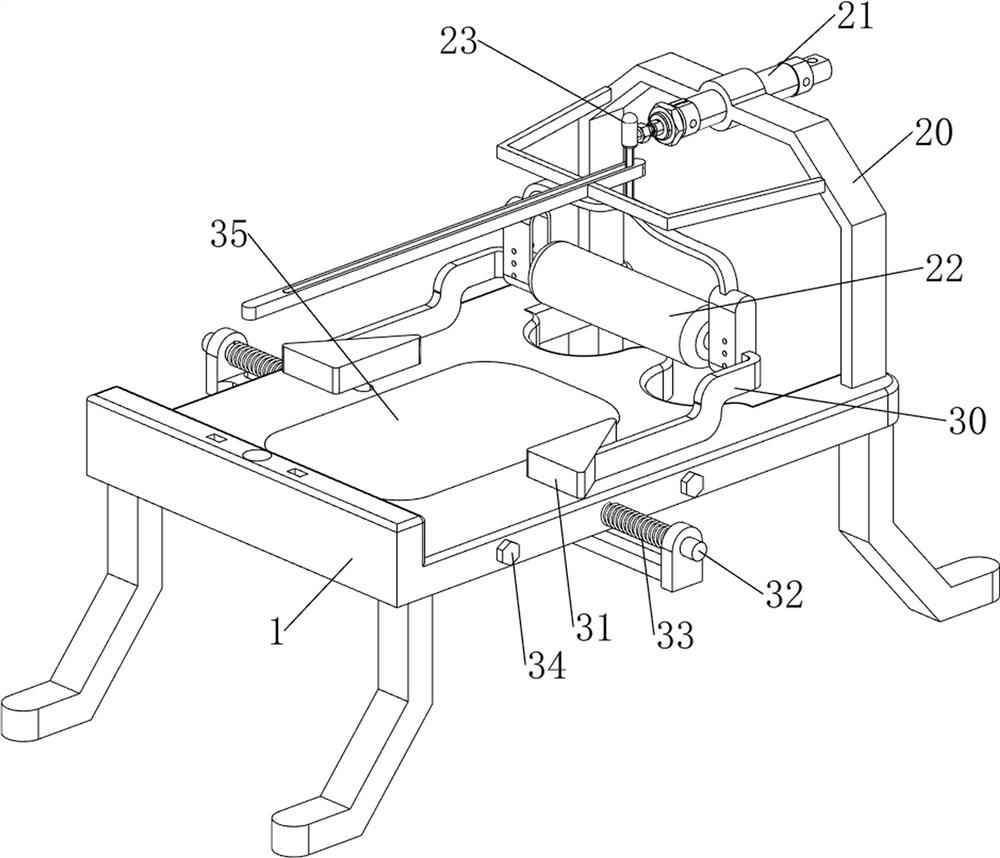

[0031] A kind of rare earth metal alloy plate surface grinding equipment, such as figure 1 with figure 2 As shown, it includes a base 1 , a grinding mechanism 2 and a clamping mechanism 3 , the top right side of the base 1 is connected to the grinding mechanism 2 , and the upper left side of the base 1 is connected to the clamping mechanism 3 .

[0032] Grinding mechanism 2 comprises support plate 20, cylinder 21, slide rail 23 and grinding wheel 22, base 1 upper right side is connected with support plate 20, and support plate 20 top is equipped with cylinder 21, and cylinder 21 telescoping rod is connected with slide rail 23, A grinding wheel 22 is slidably connected to the bottom of the slide rail 23 .

[0033] The clamping mechanism 3 includes an extruding rod 30, a first wedge block 31, a first guide rod 32, a first spring 33, a bolt 34 and a supporting plate 35, the front and rear sides of the slide rail 23 are connected with an extruding rod 30, and the base 1 The fir...

Embodiment 2

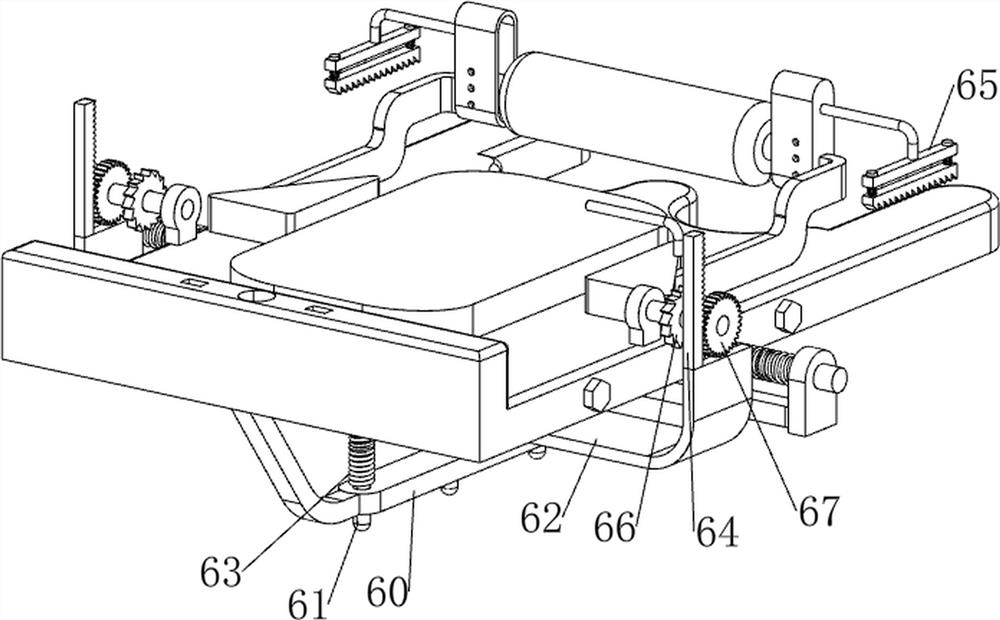

[0036] On the basis of Example 1, such as image 3 As shown, an adjustment mechanism 4 is also included. The adjustment mechanism 4 includes a first fixed plate 40, a clamping rod 41, a second spring 42 and a third spring 43, and the front and rear sides of the right part of the slide rail 23 are connected with the first fixed plate. 40, the bottom of the first fixed plate 40 on both sides is slidably connected with a clamping rod 41, and a second spring 42 is connected between the clamping rod 41 on both sides and the first fixed plate 40 on both sides, and the grinding wheel 22 and the slide rail 23 is connected with a third spring 43 .

[0037] When the surface of the rare earth metal alloy plate needs to be polished, manually pull the clamping rods 41 on both sides to move to the right and then pull the grinding wheel 22 to move upwards, the clamping rods 41 on both sides move to the right and the second springs 42 on both sides are compressed, The grinding wheel 22 moves...

Embodiment 3

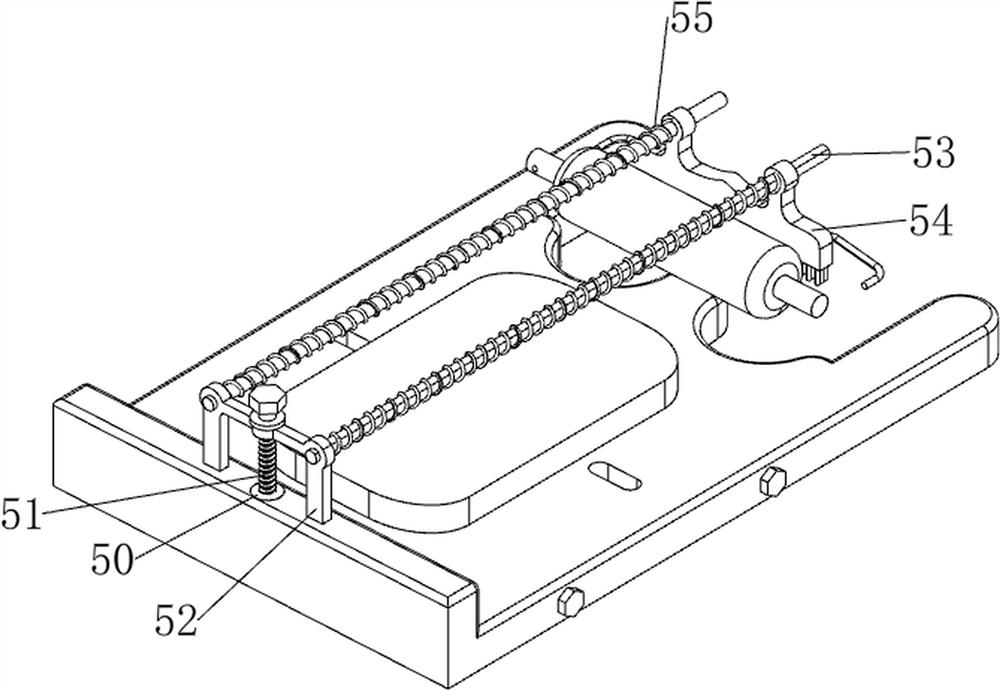

[0039] On the basis of Example 2, such as Figure 4 As shown, a cleaning mechanism 5 is also included, and the cleaning mechanism 5 includes a nut 50, a screw mandrel 51, a first connecting plate 52, a fixed rod 53, a brush 54 and a fourth spring 55, and the left side of the base 1 top is connected with a nut 50 , the upper part of the nut 50 is threadedly connected with a screw rod 51, the upper left side of the base 1 is slidably connected with a first connecting plate 52, the first connecting plate 52 is threadedly connected with the screw rod 51, and the front and rear sides of the upper part of the first connecting plate 52 are both The fixed rod 53 is connected in rotation, and the brush 54 is slidingly connected between the right sides of the fixed rod 53 on both sides. The brush 54 is in contact with the first fixed plate 40 on both sides. A fourth spring 55 is sleeved therebetween.

[0040] When the slide rail 23 moved to the left, the slide rail 23 moved to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com