A Method for Simultaneous Preparation of Phospholipid Microtubules and Vesicles Using Electric Field of Point Surface Electrode

A point-surface electrode and phospholipid technology, which is applied in the field of simultaneous preparation of phospholipid microtubules and vesicles, can solve the problems of not being able to prepare phospholipid microtubules and vesicles at the same time, and achieve high yield, low energy consumption, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

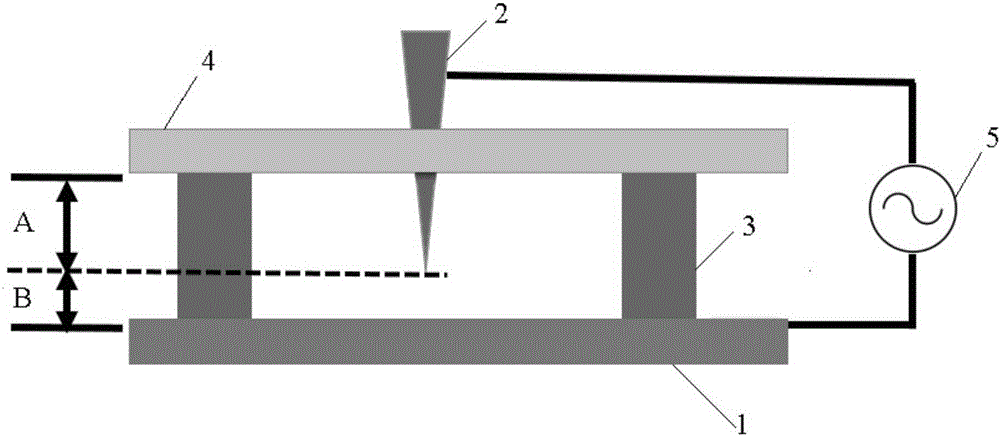

[0017] Specific implementation mode one: combine figure 1 , this embodiment is a method for simultaneously preparing phospholipid microtubules and vesicles by using the electric field of a point-surface electrode, specifically, it is completed according to the following steps:

[0018] 1. Clean the electrode: use absolute ethanol and distilled water as cleaning agents to clean the ITO electrode in sequence, and then blow it dry with nitrogen to obtain the cleaned ITO electrode; soak the tungsten needle electrode in the chromic acid solution for 3h to 6h, and then Rinse with distilled water for 3 to 6 times, and then blow dry with nitrogen to obtain a cleaned tungsten needle electrode;

[0019] 2. Preparation of phospholipid dry film: Dissolve phospholipids in chloroform to obtain phospholipid / chloroform solution; then evenly coat 1 μL to 10 μL of phospholipid / chloroform solution on the conductive surface of the cleaned ITO electrode, and dry naturally at room temperature for 2...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that: in step 1, use absolute ethanol and distilled water as cleaning agents to perform ultrasonic cleaning on the ITO electrode for 5 minutes to 20 minutes, and then dry it with nitrogen to obtain Cleaned ITO electrode. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of the chromic acid solution described in step 1 is 5-12%. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com