Front suspension assembly

A front suspension and assembly technology, applied in the direction of power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of increasing the stiffness of the front suspension, poor comfort, and difficult layout, so as to avoid vibration and noise The effect of increasing, improving the service life, and ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

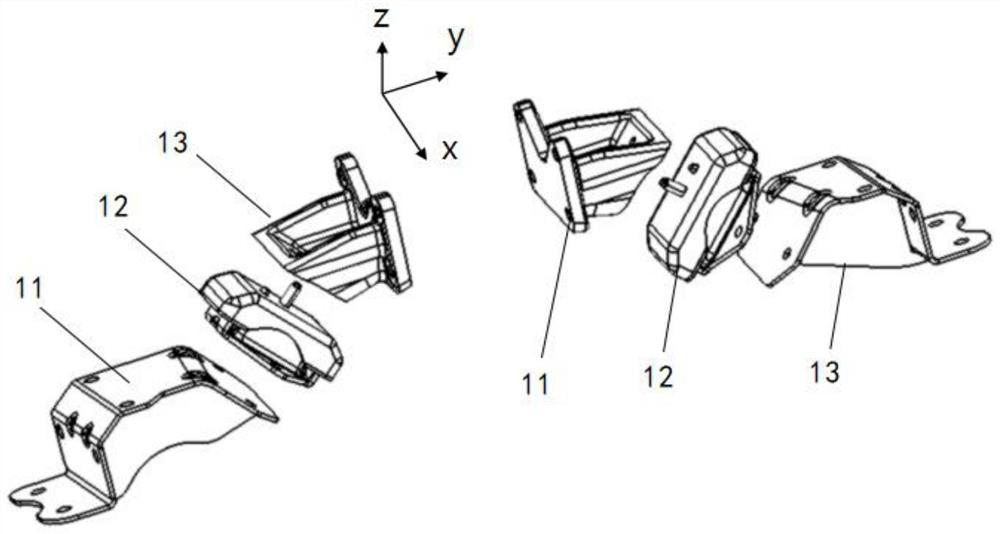

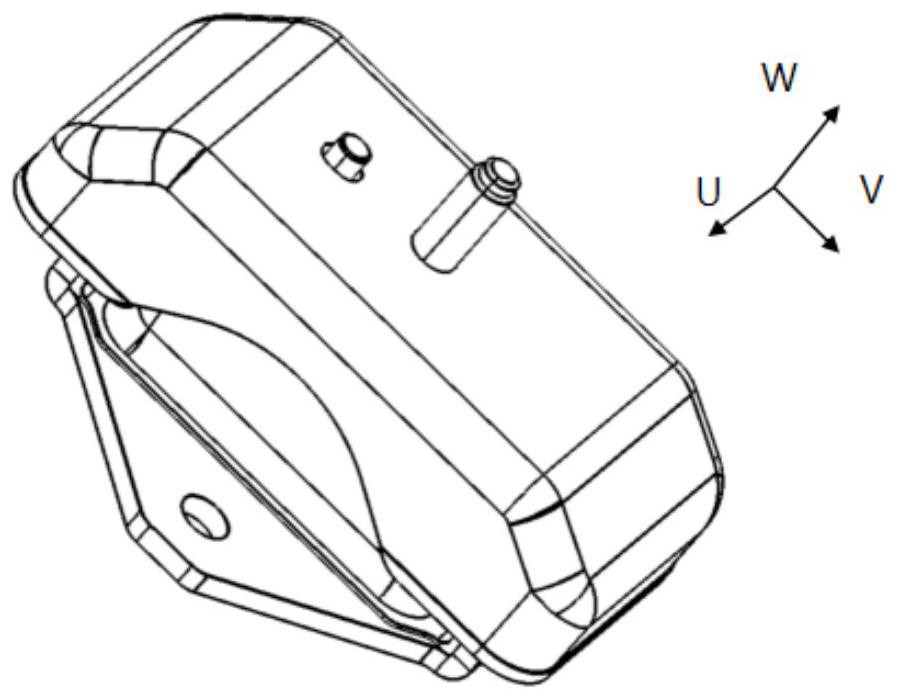

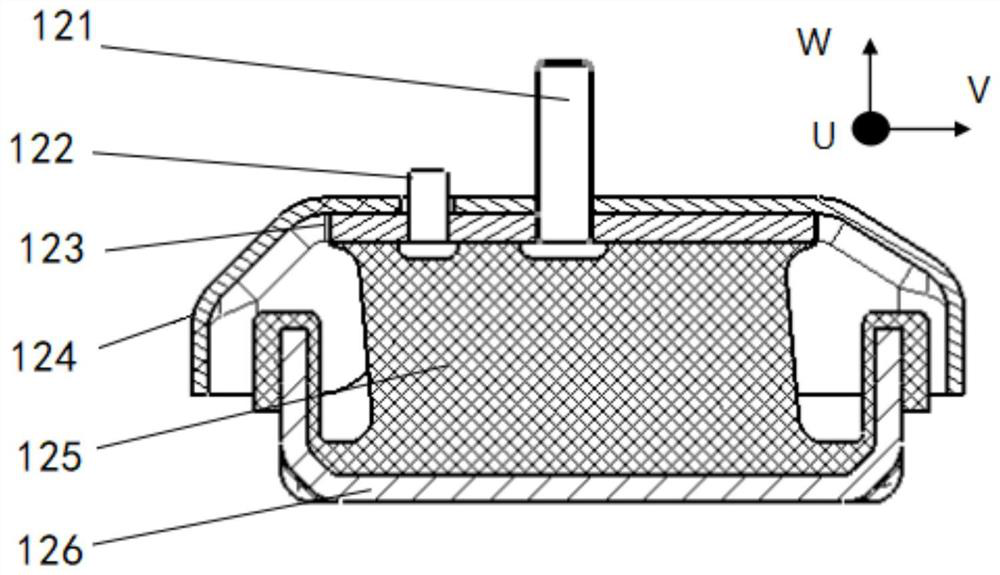

[0044] Such as Figure 5 to Figure 10 As shown, the embodiment of the present invention provides a front suspension assembly, which includes a front suspension upper plate 21, a mounting stud 23, a positioning pin 22, a front suspension lower plate 24, a rubber main spring 31, a limit screw column 41, the front suspension upper plate 21 is arranged on the top surface of the rubber main spring 31, and the front suspension lower plate 24 is arranged on the bottom surface of the rubber main spring 31; the positioning pin 22 and The mounting studs 23 are respectively arranged on the front suspension upper plate 21, and the rubber main spring 31 is provided with a first accommodation hole 311 for accommodating the limit head of the positioning pin, for accommodating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com