Quantitative oiling device and oiling method thereof

A technology of oil injection device and oil injection pipe, which is applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., and can solve the problems of small oil injection coverage of oil injection device, inconvenient quantitative oil injection treatment, pressurized oil injection work intensity and Pressure and other problems, to achieve the effect of reducing the intensity and pressure of oil injection work, easy to take out, and convenient to fix the limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

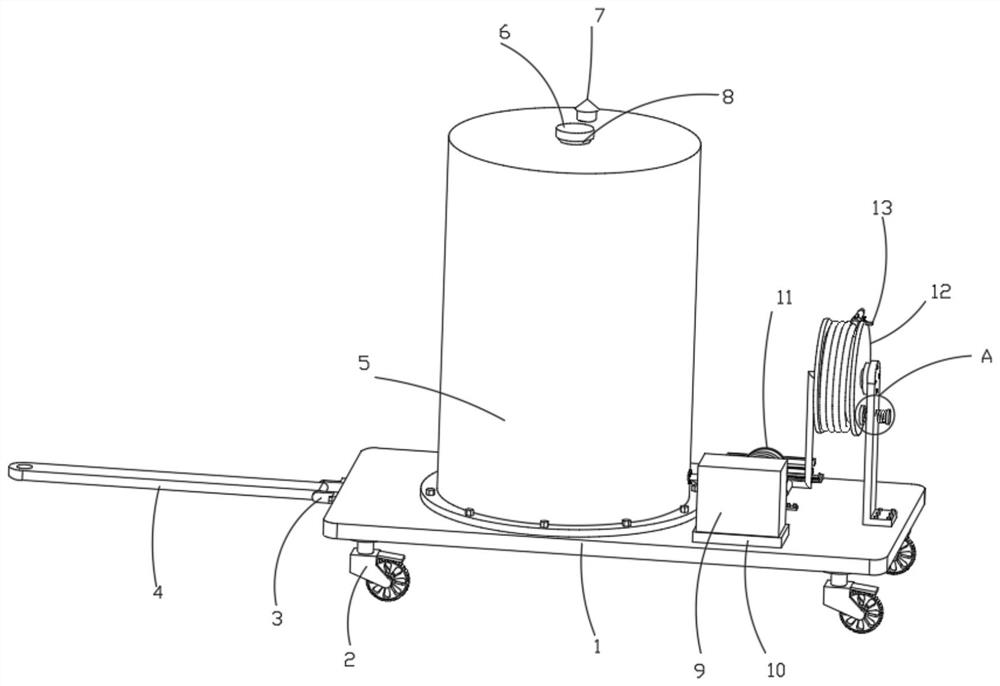

[0043] Such as figure 1 , 2 , a quantitative oiling device shown in 3, 4, 5, 6, 7, including a base 1, the bottom of the base 1 is symmetrically fixedly connected with a universal wheel 2, and one end of the base 1 is connected with a traction structure, and the traction structure includes a first L Shaped plate 3 and traction plate 4, the first L-shaped plate 3 is symmetrically fixedly installed on one end of base 1, the first L-shaped plate 3 is rotatably connected with traction plate 4 through a fixedly connected bearing, and traction plate 4 is connected with the external power structure;

[0044] One end of the top of the base 1 is connected with an oil storage tank 5, the top of the oil storage tank 5 is fixedly connected with an oil injection pipe 8 for oil injection, and the top of the oil injection pipe 8 is movably connected with a cap 6, 6 and 8 can be sealed, The top of the tank is connected with a breather valve 7 for balancing the pressure of the oil storage tan...

Embodiment 2

[0047] Embodiment 2 is a further improvement to Embodiment 1.

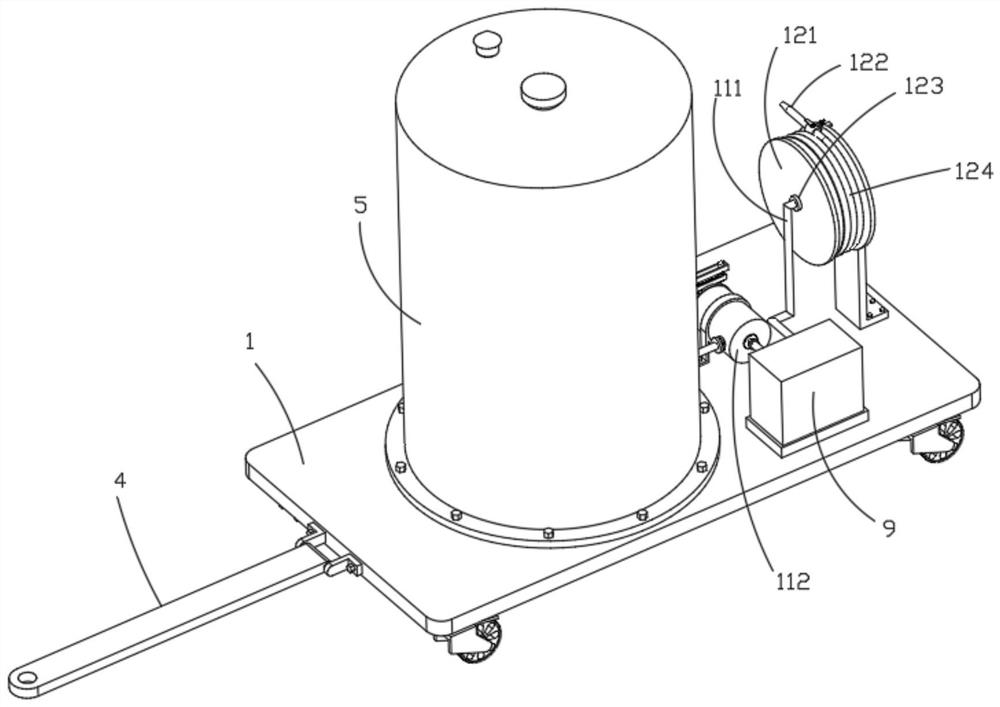

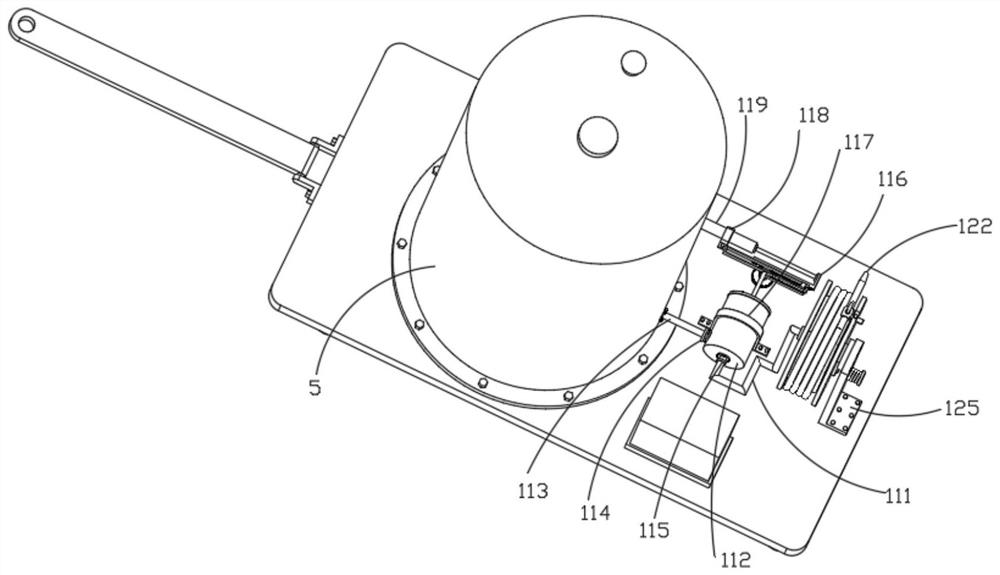

[0048] Such as figure 2 , 3 , 8, the damping winding structure 12 includes a hollow winding roller 121, an oil pipe 122, a sealed bearing 123, a hose 124, a second L-shaped plate 125, a first spring 126, a circular plate 127, a transverse shaft 128, Connecting pipe 129, rubber ring 1210, cross bar 1211, control valve 1212 and connecting sleeve 1213, the second L-shaped plate 125 is fixedly installed on the top of the base 1, and the top of the side wall of the second L-shaped plate 125 rotates through the fixedly connected bearing Connected with a horizontal shaft 128, the horizontal shaft 128 is fixedly connected with a hollow winding roller 121, the left end of the hollow winding roller 121 is fixedly connected with a sealed bearing 123, and the inner wall of the outer ring of the sealed bearing 123 is fixedly connected with a connecting pipe 129, and the connecting pipe 129 The top is fixedly connected with ...

Embodiment 3

[0050] Embodiment 3 is a further improvement to Embodiment 1.

[0051] Such as Figure 9 The hollow winding roller 121 shown is connected with a fixed structure 13 for the fixed connection of the connecting sleeve 1213. The fixed structure 13 includes a lock pin 131, a second spring 132, a horizontal plate 133 and a chute 134. The chute 134 is provided in the hollow winding roller. The side wall of the roller 121, the hollow winding roller 121 is fixedly connected with the second spring 132 at the top of the chute 134, the top of the second spring 132 is fixedly connected with the lock pin 131, and the outer wall of the connecting sleeve 1213 is fixedly connected with the chute 134 fits the horizontal plate 133 that is slidingly connected, and the bottom of the locking pin 131 penetrates the hollow winding roller 121 and is plugged into the top hole of the horizontal plate 133, and the horizontal plate 133 is pulled out from the chute 134 to pull the damping winding structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com