Split type electric power tower group installation method

An installation method and technology of power towers, applied in towers, wind power generation, building types, etc., can solve problems such as difficult detection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

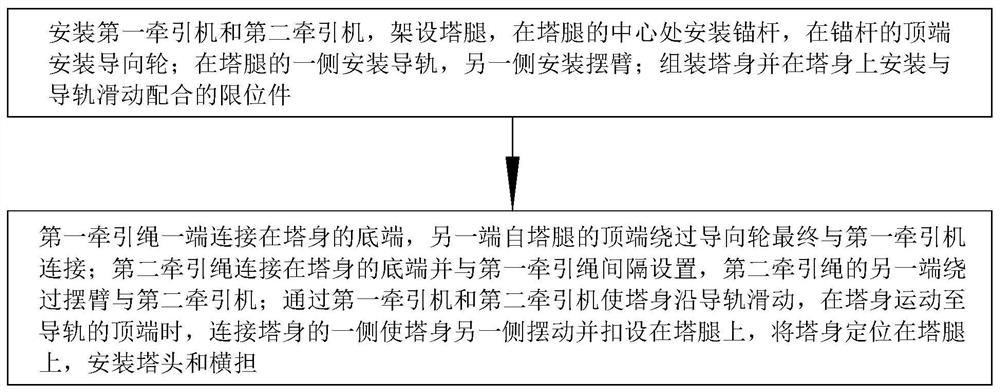

Method used

Image

Examples

specific Embodiment approach

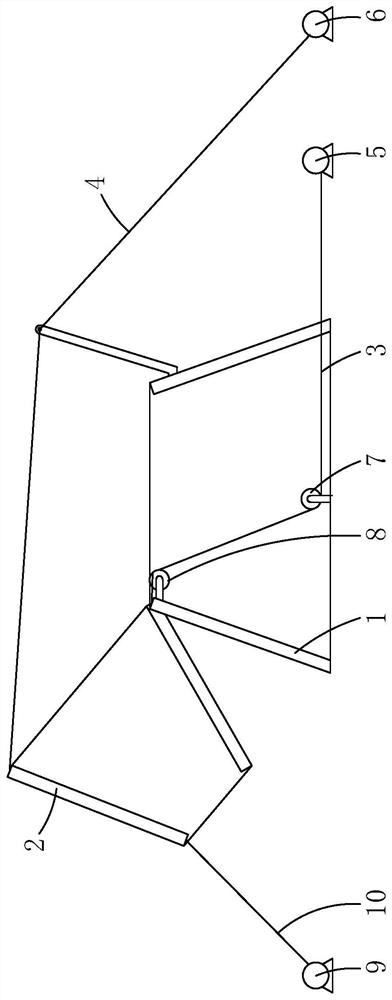

[0065] As a specific embodiment of the installation method of a split type power tower group provided by the present invention, after positioning the tower body 2 on the top of the tower leg 1, it also includes:

[0066] Remove the fixed pulley 8 and the swing arm from the tower leg 1, and install them on the corresponding position of the tower body 2, install the auxiliary rail on the same side where the tower body 2 is located on the guide rail, install the tower head through the auxiliary rail and the guide rail, and install the second A traction rope 3 and a second traction rope 4 are respectively connected to both sides of the tower head.

[0067] In order to reduce the use of materials, the reinforcement bar, the swing arm and the fixed pulley 8 can all be detachably connected in this application. After the tower body 2 is installed, the swing arm and the fixed pulley 8 can be installed at the pre-specified position on the top of the tower body 2. On, for the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com