A carbon dioxide ultrasonic vibration foaming device and its grading enhanced fracturing method

A technology of carbon dioxide and ultrasonic vibration, which is applied in the field of coal seam fracturing, can solve the problems of difficulty in implementing the carbon dioxide foam fracturing process, large amount of foam bursting, and affecting the fracturing effect, so as to reduce the transmission process time, improve work efficiency, and improve Effect of Foam Quality and Fracturing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

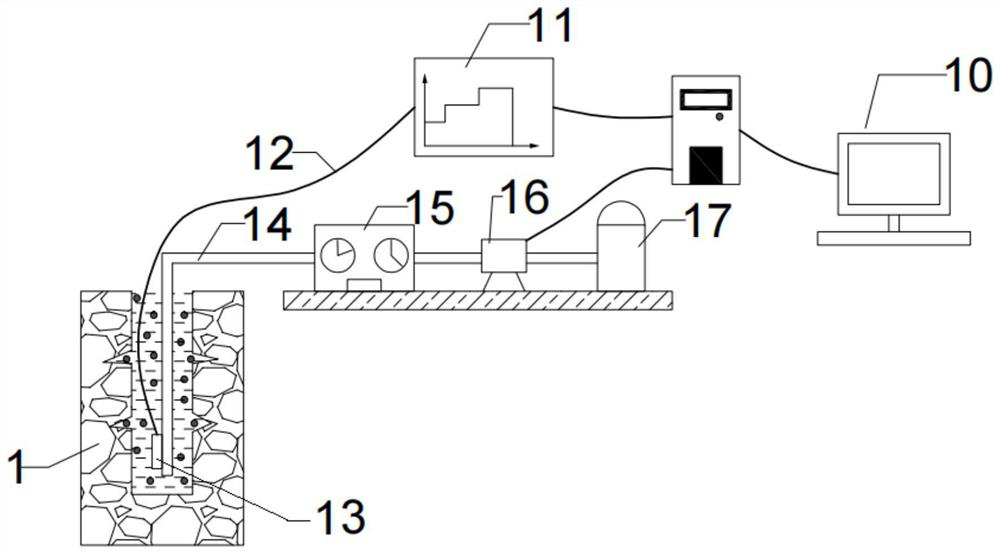

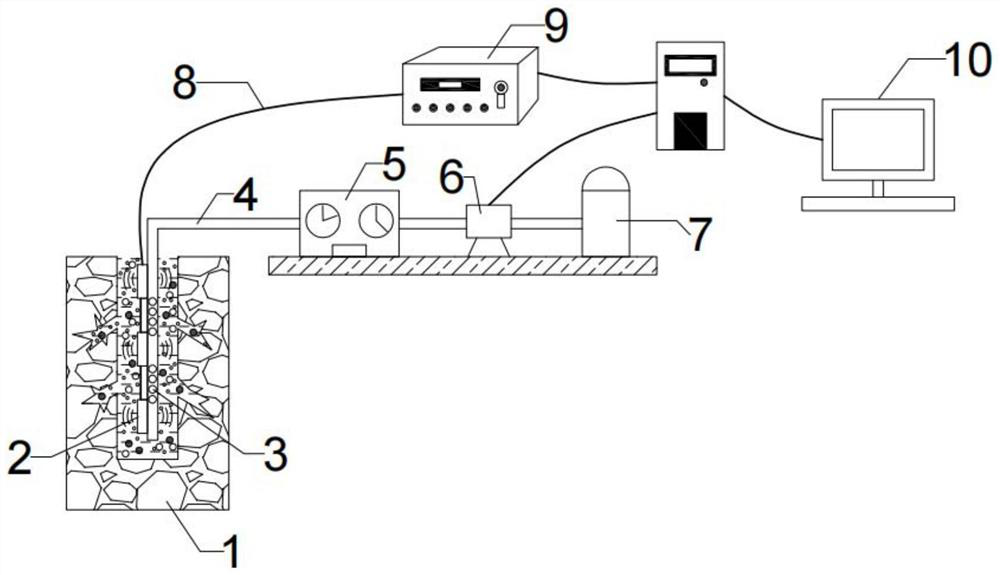

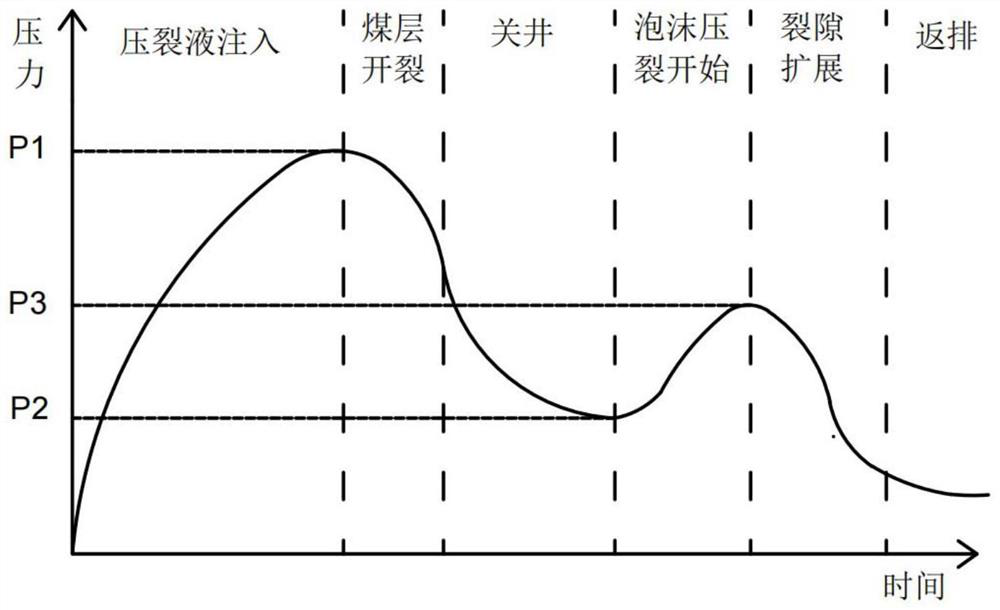

[0038] like Figure 1-3 As shown, a carbon dioxide ultrasonic vibration foaming device is mainly composed of a water-based fracturing system, a pressure monitoring system, a high-pressure gas injection system, an ultrasonic vibration system and a central control system 10 .

[0039] The water-based fracturing system is mainly composed of a fracturing fluid storage tank 17, a high-pressure water pump 16 and a high-pressure pipeline 14; the water inlet end of the high-pressure water pump 16 is connected to the fracturing fluid storage tank 17, and the water outlet end of the high-pressure water pump 16 is connected to the high-pressure pipeline 14 is connected to the water inlet end. A water injection console 15 is arranged on the high pressure pipeline 14 , and a water flow meter and a water pressure gauge are arranged in the water injection console 15 , so that the water flow and water pressure of the high pressure water pump 16 can be monitored manually.

[0040] The pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com