Hydraulic part fault automatic processing device

A technology of automatic processing and hydraulic parts, applied in the field of hydraulic control, can solve the problems of inability to real-time monitoring, hydraulic punch breakage failure, low efficiency, etc., to achieve the effect of easy troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

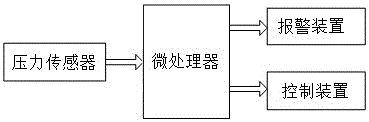

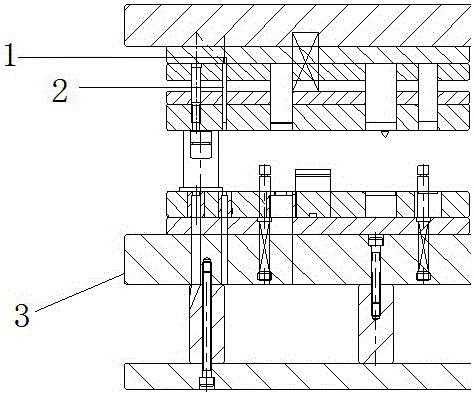

[0015] like figure 1 , figure 2 As shown, a hydraulic component failure automatic processing device includes a plurality of punches 2, and the punches 2 are arranged on the mold assembly 3, and a pressure sensor 1 is provided at the bottom of each punch 2, and the The pressure sensor 1 is connected to the input end of the microprocessor, the output end of the microprocessor is connected to the alarm device, and the output end of the microprocessor is also connected to the hydraulic cylinder control device.

[0016] In this example. The device includes multiple sets of hydraulic cylinder control devices. The punch 2 adopts punching needles or punches. The hydraulic cylinder control devices are relays and solenoid valves. The hydraulic pressure is controlled by relays. The alarm device described above is an audible and visual alarm or a liquid crystal display.

[0017] It can monitor the pressure data of the punch 2 in real time during the production process, and determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com