High-performance self-suction solid treatment garbage pump convenient for self-cleaning

A self-cleaning, high-performance technology, applied in grain processing, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as low intelligence, troublesome handling, and existence, and achieve faster suction and smart use High performance and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

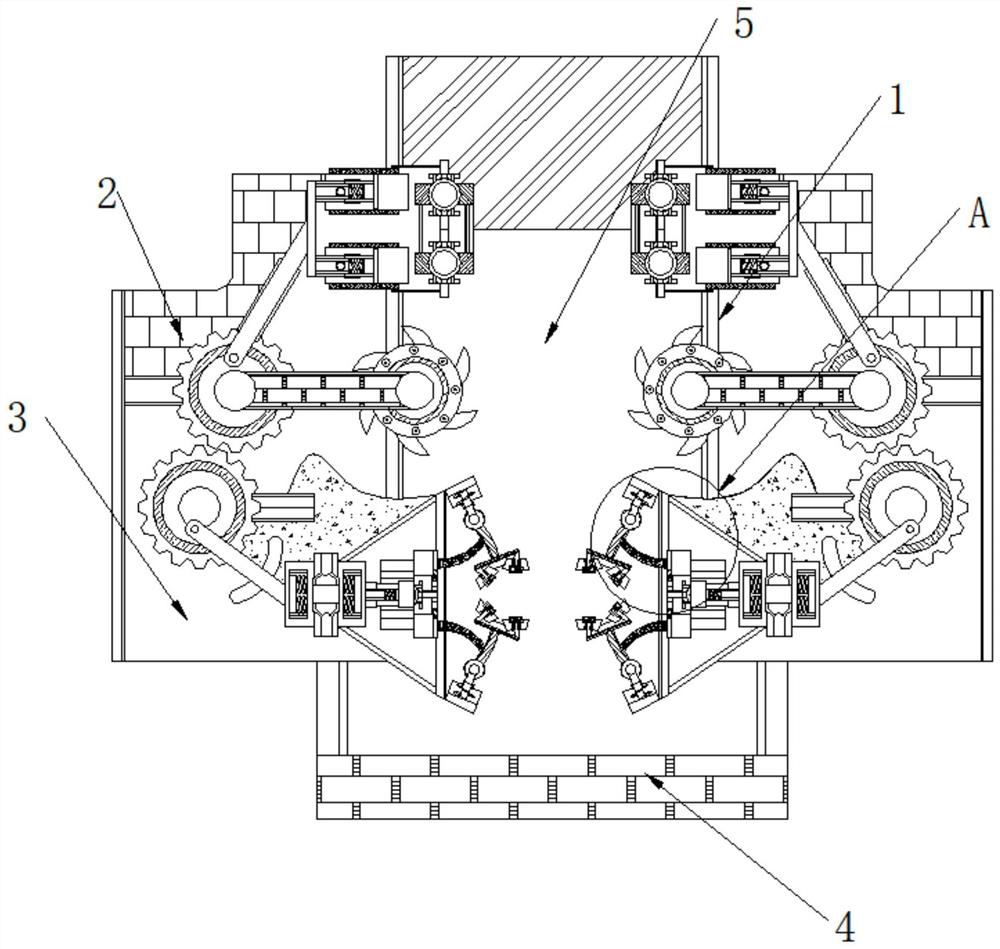

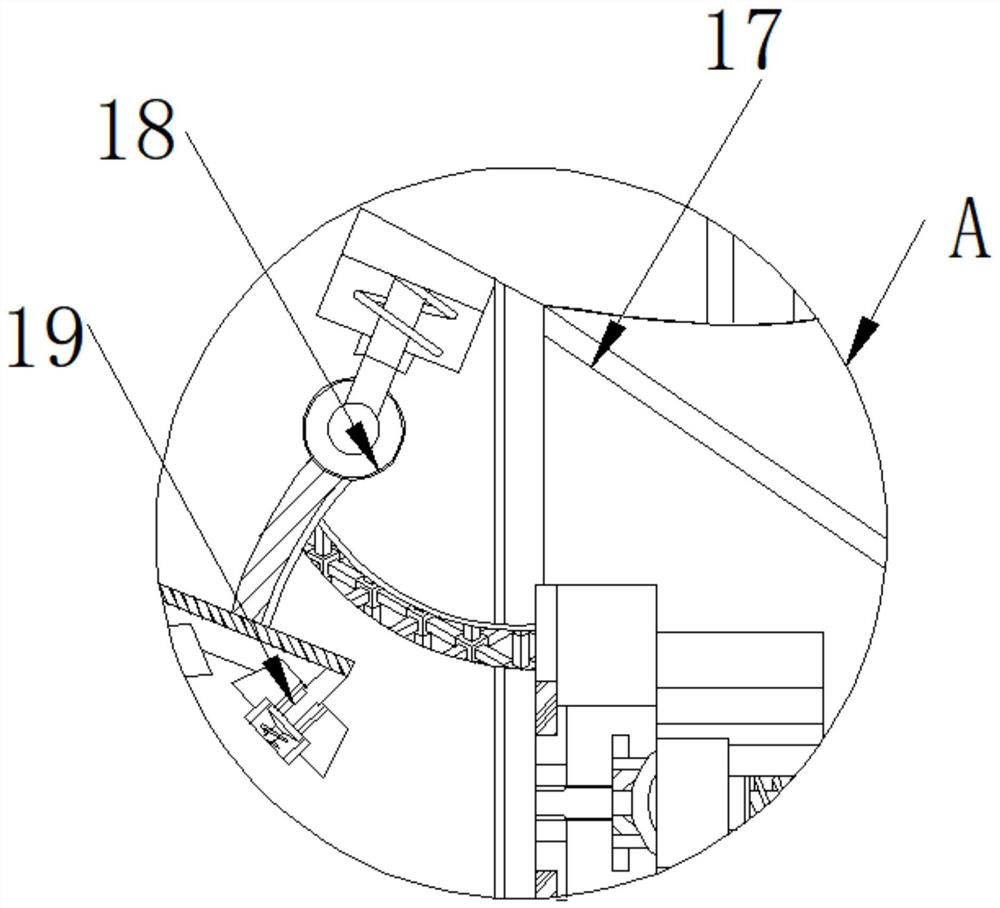

[0020] As shown in Figure 1 to Figure 4:

[0021] A convenient self-cleaning high-performance self-priming solid treatment garbage pump, comprising a garbage pump main body 1 and a protective mechanism 2, the garbage pump main body 1 includes a protective cover 3, the outer surface of the protective cover 3 is movably connected with a rear cover 4, The inside of the protective cover 3 is fixedly connected with a pump body pumping cavity 5 .

[0022] The protective mechanism 2 includes a connecting seat 6, the inner part of the connecting seat 6 is connected with a connecting plate 7 for rotation, and the outer surface of the connecting plate 7 is movably connected with an arc-shaped blade 8.

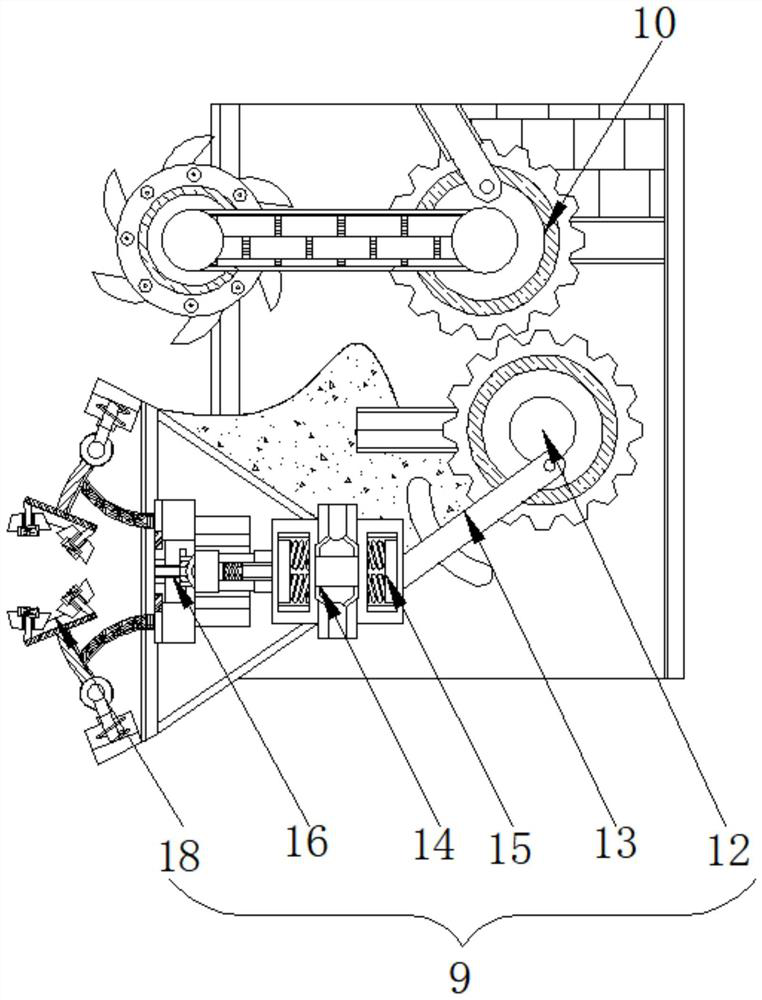

[0023] Further, it also includes a cleaning mechanism 9, the cleaning mechanism 9 includes a first connecting gear 10, the outer surface of the first connecting gear 10 and the outer surface of the connecting plate 7 are movably connected with a transmission chain 11, and the outer surfa...

specific Embodiment approach 2

[0025] As shown in Figure 3 to Figure 4:

[0026] A convenient self-cleaning high-performance self-priming solid treatment garbage pump, comprising a garbage pump main body 1 and a protective mechanism 2, the garbage pump main body 1 includes a protective cover 3, the outer surface of the protective cover 3 is movably connected with a rear cover 4, The inside of the protective cover 3 is fixedly connected with a pump body pumping cavity 5 .

[0027] Further, it also includes a compression mechanism 20, the compression mechanism 20 includes a compression chamber seat 21, the interior of the compression chamber seat 21 is movably connected with a piston seat 22, the outer surface of the piston seat 22 is fixedly connected with a moving column 23, and the internal movement of the moving column 23 A pressure spring 24 is connected, a bias rod 25 is movably connected to the outer surface of the moving column 23 , and an air delivery port 26 is movably connected to the outer surface...

specific Embodiment approach 3

[0029] As shown in Figure 1 to Figure 4:

[0030] A convenient self-cleaning high-performance self-priming solid treatment garbage pump, comprising a garbage pump main body 1 and a protective mechanism 2, the garbage pump main body 1 includes a protective cover 3, the outer surface of the protective cover 3 is movably connected with a rear cover 4, The inside of the protective cover 3 is fixedly connected with a pump body pumping cavity 5 .

[0031] The protection mechanism 2 includes a connecting seat 6, the inner part of the connecting seat 6 is connected with a connecting plate 7, and the outer surface of the connecting plate 7 is movably connected with an arc-shaped blade 8, and the cleaning mechanism 9 includes a first connecting gear 10, the first connecting gear 10 The outer surface and the outer surface of the connecting disc 7 are movably connected with a transmission chain 11, the outer surface of the first connecting gear 10 is meshed with a second connecting gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com