Pressure vessel leakage detection system and working method thereof

A pressure vessel and leak detection technology, applied in signal transmission systems, testing of machine/structural components, instruments, etc., can solve the problems of increasing safety, failure to detect leaks in time, lack of real-time monitoring of pressure vessels, etc. Safety and effect of preventing leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

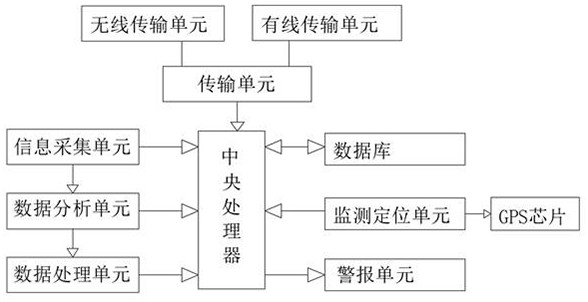

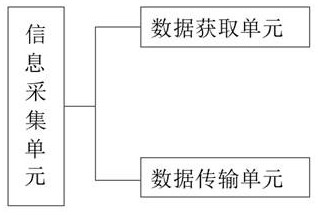

[0030] Such as Figure 1-4 As shown, the present invention provides a technical solution: a pressure vessel leak detection system includes a central processing unit, an information collection unit, a data analysis unit, a data processing unit, a database, a monitoring and positioning unit, an alarm unit and a transmission unit, and the information collection unit The data output end of the data analysis unit is connected with the data receiving end of the database, the data analysis unit transmits the analyzed data result to the data processing unit, and the data processing unit transmits the processing result to the central processing unit, so The alarm unit performs an alarm reminder according to the data information fed back by the central processor, the database is connected to the central processor, the monitoring and positioning unit is connected to the information collection unit and follows the information collection unit to transmit data back to the central processor, ...

Embodiment 2

[0040] Such as Figure 1-4 As shown, the present invention provides a technical solution: a working method of a pressure vessel leak detection system, comprising the following steps:

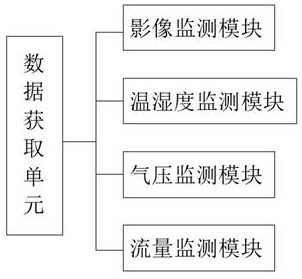

[0041] S1. The image detection module, temperature and humidity monitoring module, air pressure monitoring module, and flow monitoring module in the information acquisition unit monitor the temperature, humidity, internal air pressure, and flow rate of each group of pressure vessels in real time, and feed back the collected data to the In the database of the data analysis unit and the central processor, the monitoring and positioning unit follows the information collection unit and transmits the position information of the monitoring point to the database of the data analysis unit and the central processor;

[0042] S2. After the data analysis unit receives the data, it analyzes and processes the collected data, and transmits the analyzed and processed data to the data processing unit. The data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com