Pressure type cleaning device for optical brix detection surface of sugar refinery

A cleaning device and pressure technology, applied in measuring devices, material analysis by optical means, scientific instruments, etc., can solve the problems of not being able to clean the fouling, affecting the accuracy of hammer control, affecting the continuity of sugar solution, etc. Achieve the effect of ensuring energy reduction and consumption reduction, ensuring continuity, and ensuring the quality of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

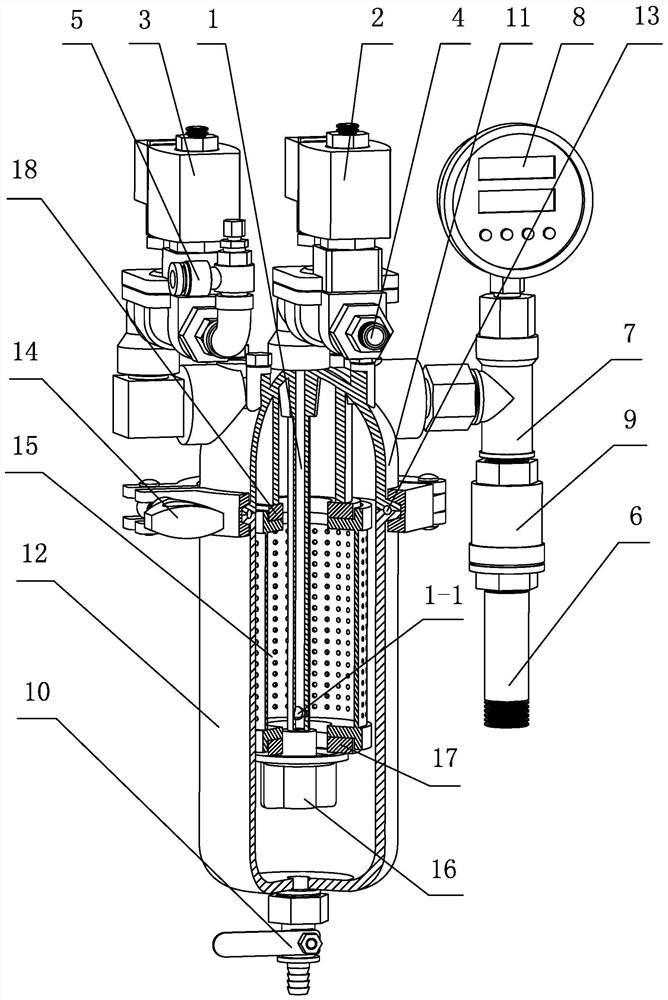

[0018] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0019] The pressure-type sugar factory optical hammer detection surface cleaning device of the present invention, its main body is a gas storage liquid tank, the gas storage liquid tank includes a tank cover 11 and a tank body 12, the lower cover opening of the tank cover 11 and the tank body 12 After the upper tank mouth is docked, the two are fixedly connected with a hoop 14. A sealing ring 13 is provided between the butt joint surface of the tank body 12 and the tank cover 11, and a support that is connected to the bottom of the tank cover 11 is coaxially provided. cover; the bottom center of the tank body 12 is provided with a slag discharge port, and the bottom of the tank body 12 is provided with a discharge valve 10 installed on the slag discharge port, such as figure 1 shown.

[0020] The top of the tank cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com