Combined type casing milling joint device and construction method thereof

A joint device and combined technology, which is applied in the combined sleeve milling joint device and its construction field, can solve the problems of increased project cost, water leakage at the joint position, and unevenness, so as to improve the water-stop performance and impermeability , enhance the smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

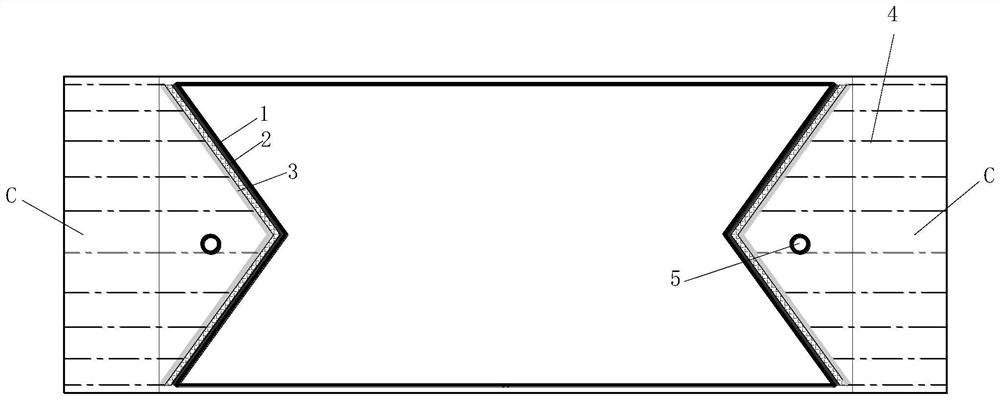

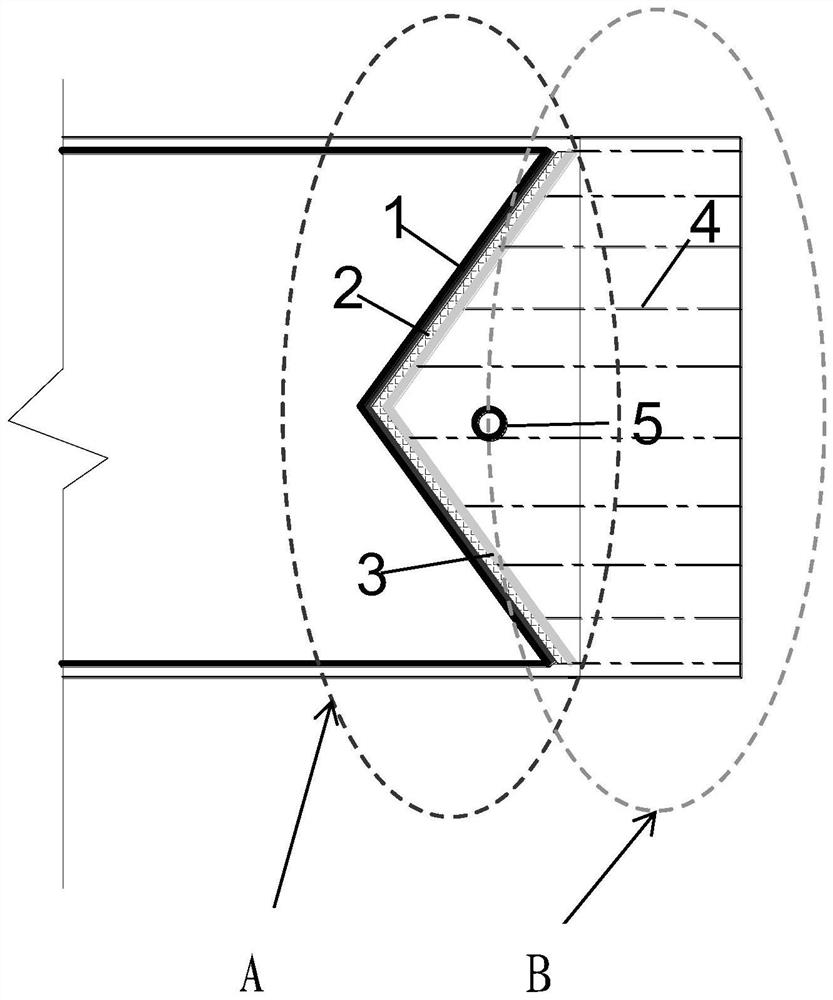

[0036] see Figure 1-2 , the combined joint device is connected with a conventional steel cage, which may be welded.

[0037] see Figure 1-2 , the combined joint device includes a special-shaped joint device A and an accessory device B. The attachment device B covers the milling area C of the joint; the attachment device A is adjacent to the attachment device B, and is located on the side close to the pre-grooving section, and the joint device A is strictly prohibited from intruding into the milling area C.

[0038] The joint device A consists of a 3-layer structure, which is divided into an inner layer, a middle layer and an outer layer; the accessory device includes a grouting hole 5 and a connection structure 4 . The outer layer of the joint device A is connected to the connection structure of the accessory device B.

[0039] see Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com