Fabricated slab culvert main body structure and construction method thereof

A technology of the main structure and construction method, which is applied in the direction of buildings and road bottom layers, can solve the problems of uneven construction and maintenance quality and low construction efficiency of slabs and culverts, and achieve the goals of shortening the construction period, less maintenance water, and improving the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

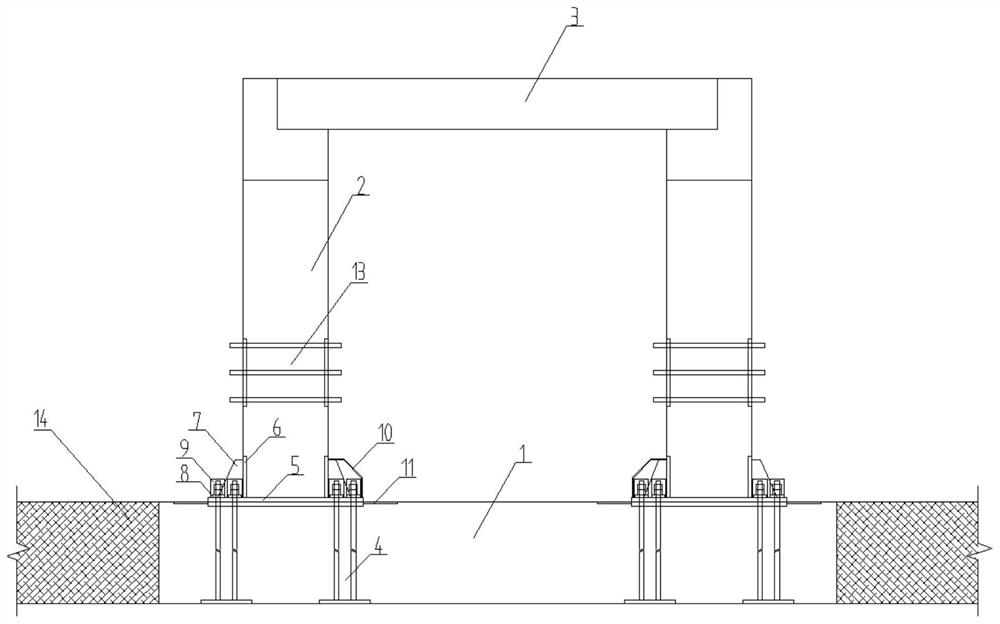

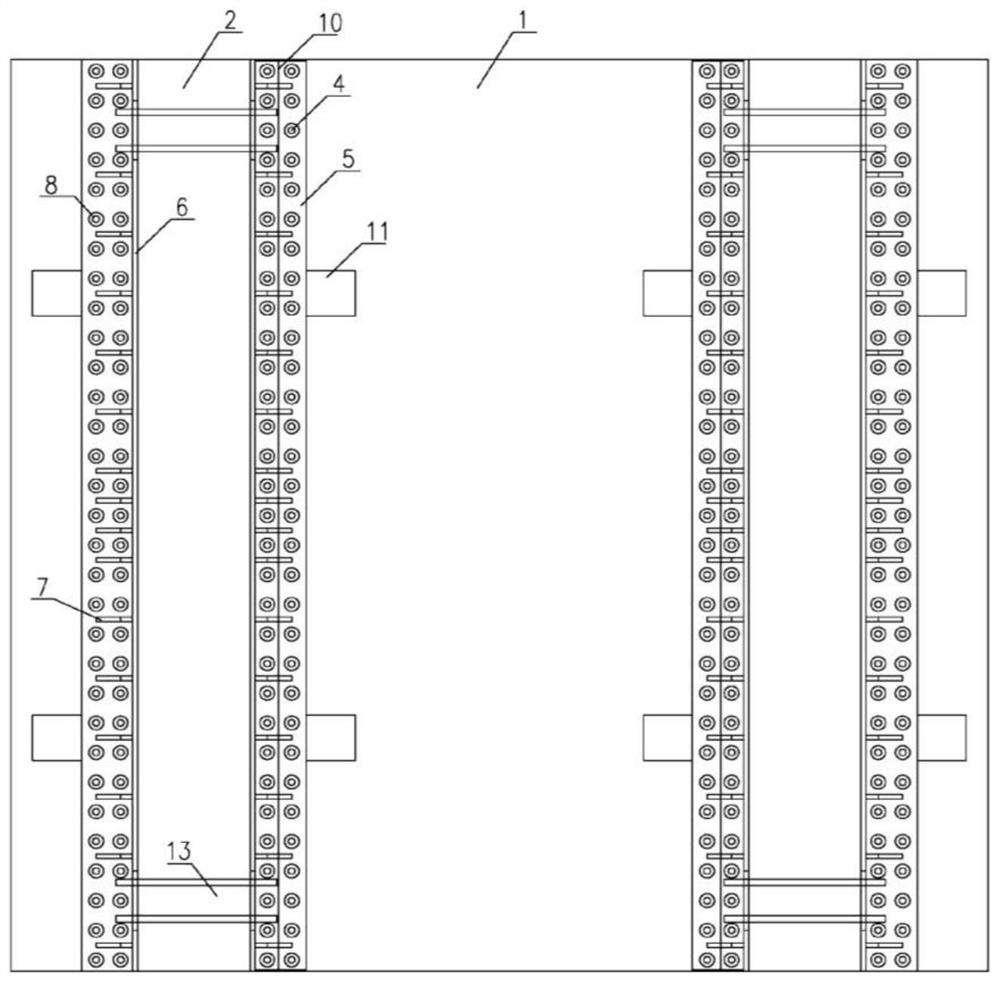

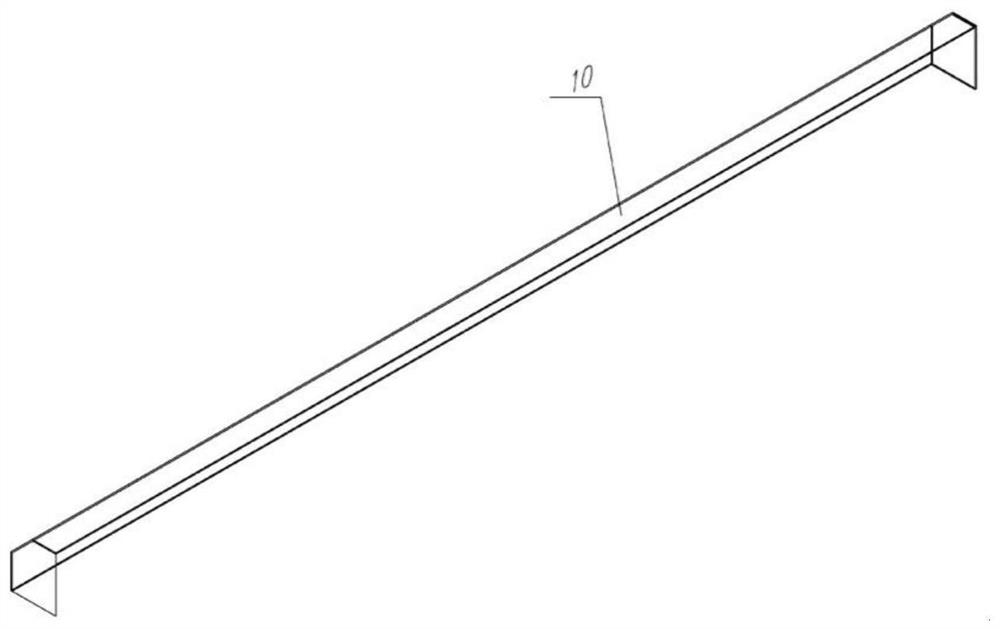

[0048] Such as Figure 1 to Figure 4 As shown, the main structure of the assembled cover plate of this embodiment includes a prefabricated base plate 1, a prefabricated platform body 2 and a prefabricated cover plate 3, anchor bolts 4 are pre-embedded in the base plate 1, and a base frame steel plate 5 is provided at the bottom of the platform body 2 , base side steel plate 6, stiffening steel plate 7 and rectangular threaded steel bar 19, base frame steel plate 5 and anchor bolt 4 are connected by double-layer nut 8, platform body 2 is provided with platform body embedded bolt 13 for installing spreader, cover The plate 3 is arranged on the platform cap at the upper end of the platform body 2, a steel glue layer is provided under the base frame steel plate 5, a stainless steel box cover 10 is provided on the water side of the bottom of the platform body 2, and the base frame steel plate 5 and The base side steel plate 6 is accommodated in the stainless steel box cover 10 . T...

Embodiment 2

[0050] Part of the steps are conventional means, and will not be repeated here. The following are the main steps of the present invention.

[0051] Such as Figure 5 As shown, the cover plate is installed to cover the bottom plate 1, the backfill material 14 on one side of the bottom plate 1 is compacted, the temporary support 151 of the platform body is installed, and the guide frame 12 is installed on the welding platform body; The height is about 13cm, and the self-weight does not exceed 25kg. Perforated lugs are arranged on the side of the top plate, and the double-layer temporary support is fixed vertically by bolts. This facilitates the handling and installation of the platform body temporary support 151 .

[0052] Such as Figure 6 and Figure 7 As shown, the temporary support 152 of the jack is installed, and the vertical space is fixed with bolts, and then the three-dimensional jack 18 is installed, and the three-dimensional jack 18 vertically tightens the cantilev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com