Bearing friction torque testing mechanism in vacuum environment

A testing mechanism, friction torque technology, applied in mechanical bearing testing, force/torque/work measuring instruments, bearing-related force sensors, etc., can solve installation errors, machining errors, and inability to obtain bearing friction data To achieve the effect of reducing errors and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

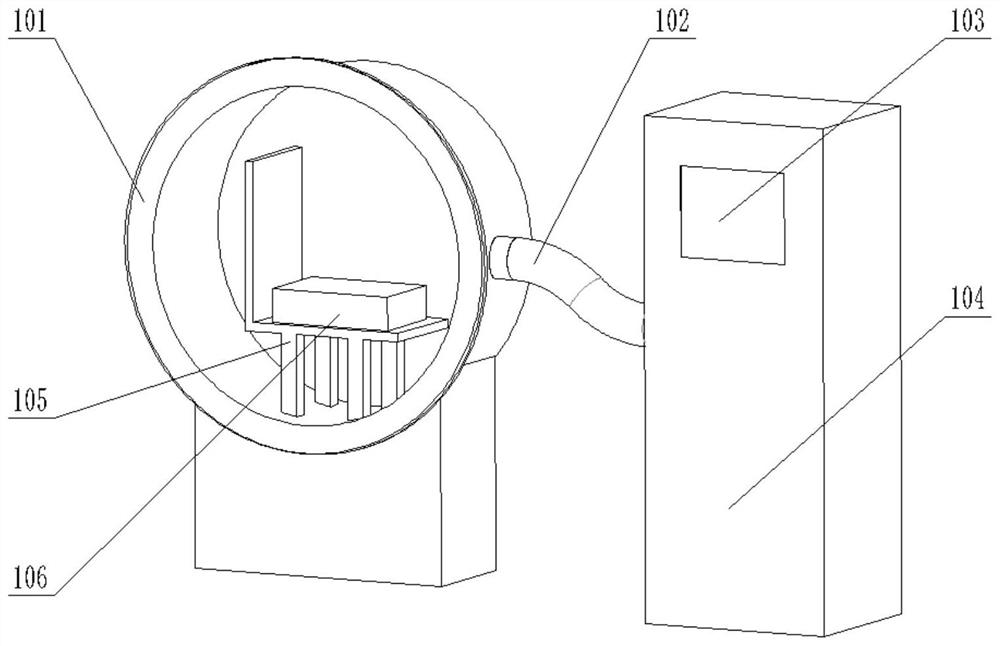

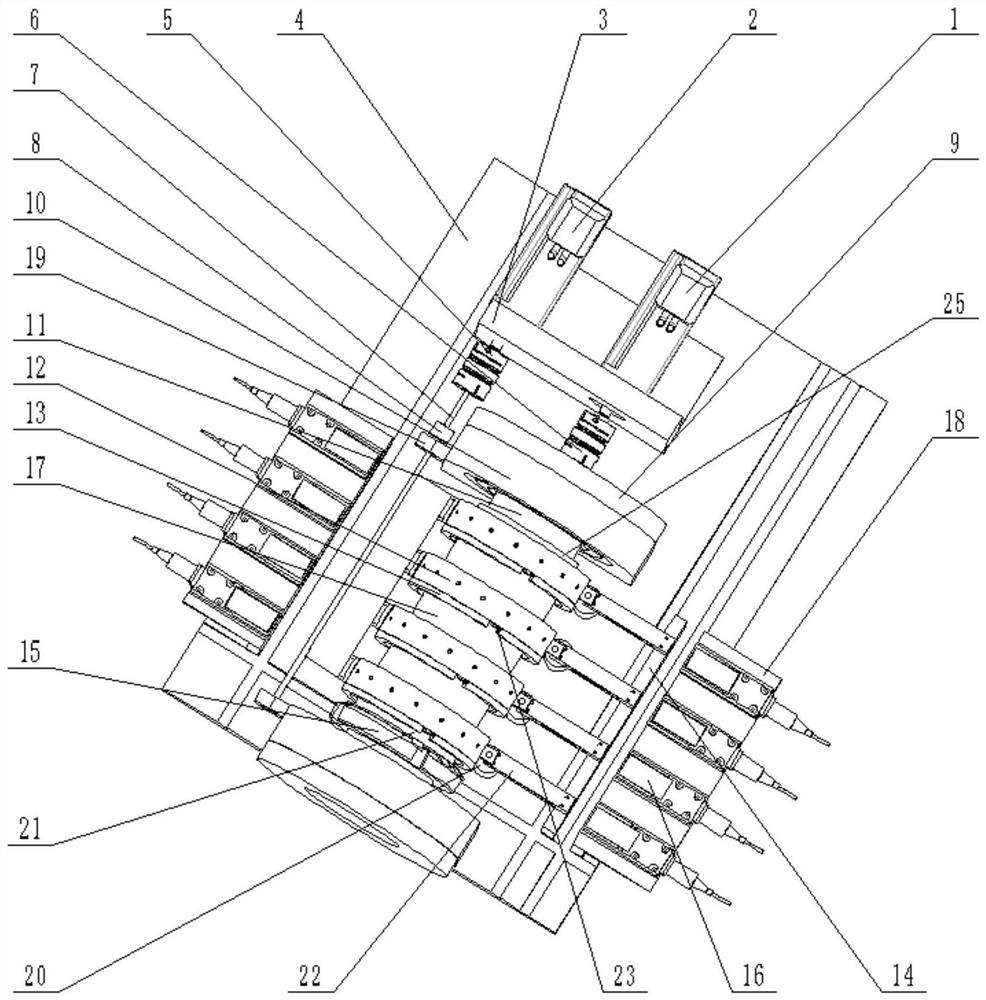

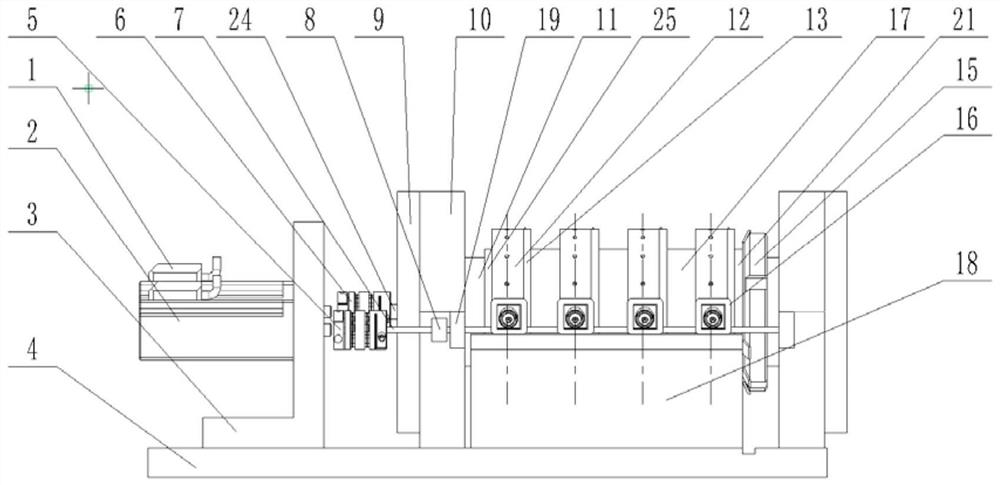

[0031] like Figure 1-7 As shown, a bearing friction torque testing mechanism in a vacuum environment includes a rotating shaft system, a friction testing mechanism, a friction arm measuring mechanism and a lever mechanism. The bearing friction torque test mechanism of the present invention is applied to the bearing friction torque test test under the vacuum environment. The bearing friction torque test mechanism 106 is installed on the installation platform 105, and the installation platform 105 is fixed in the vacuum tank 101. The vacuum tank 101 and the vacuum unit 104 Installed on the ground to avoid the influence of the motor work in the vacuum unit on the test results. The operating platform 103 and the vacuum unit 104 are integrated, placed on the side of the vacuum tank, and connected to the vacuum tank 101 through the vacuum bellows 102 .

[0032] The lever mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com