Disposable slippers production device

A production device, a one-time technology, applied in the direction of footwear, heel pads, shoe-making machinery, etc., can solve the problems of not being able to obtain the support of the upper forming device, wasting raw materials, and unqualified slippers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

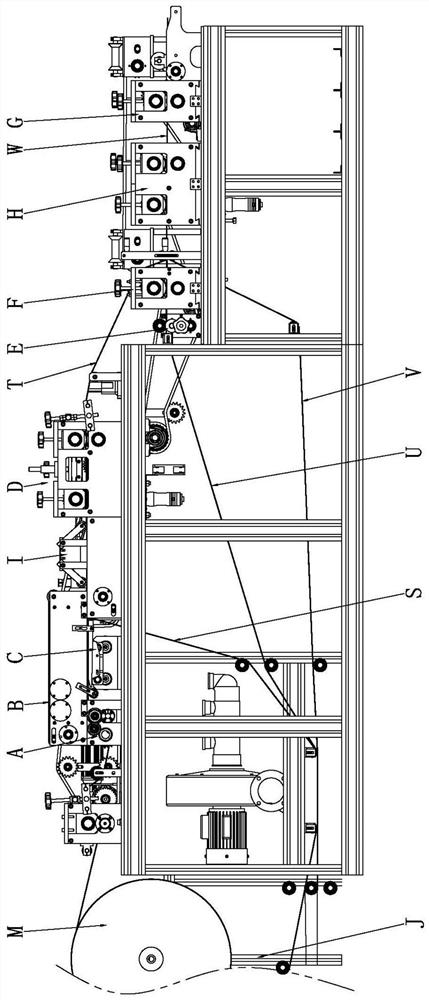

[0048] Combine below Figures 1 to 17 Explain in detail.

[0049] Disposable slippers production device, including cutting device A, conveying device B, upper molding mechanism C, first welding device D, first traction mechanism E, first cutting mechanism F, second welding mechanism H, final molding device G , the parts and their relationships are described in detail below:

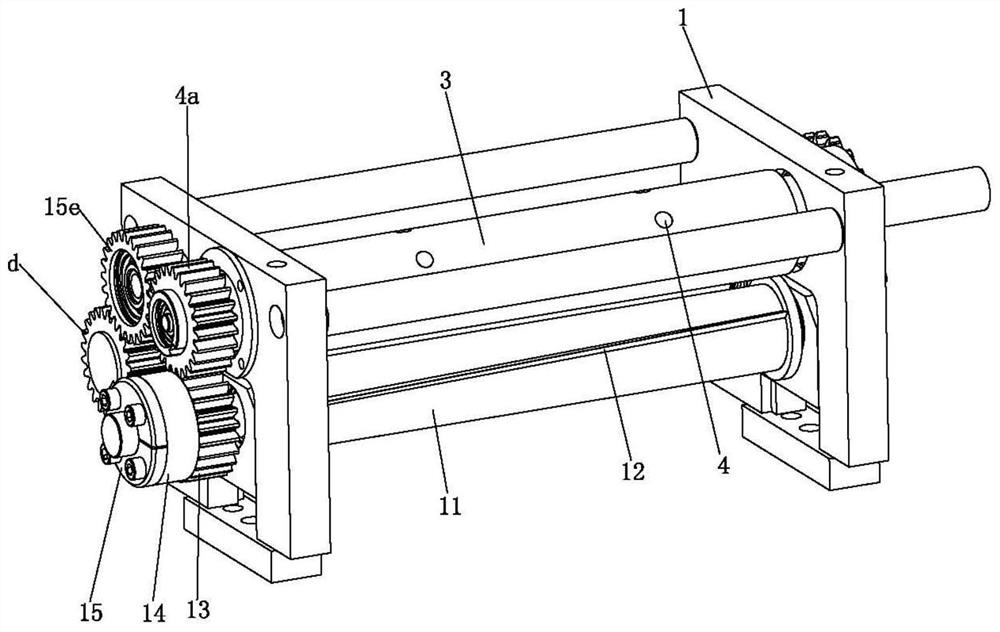

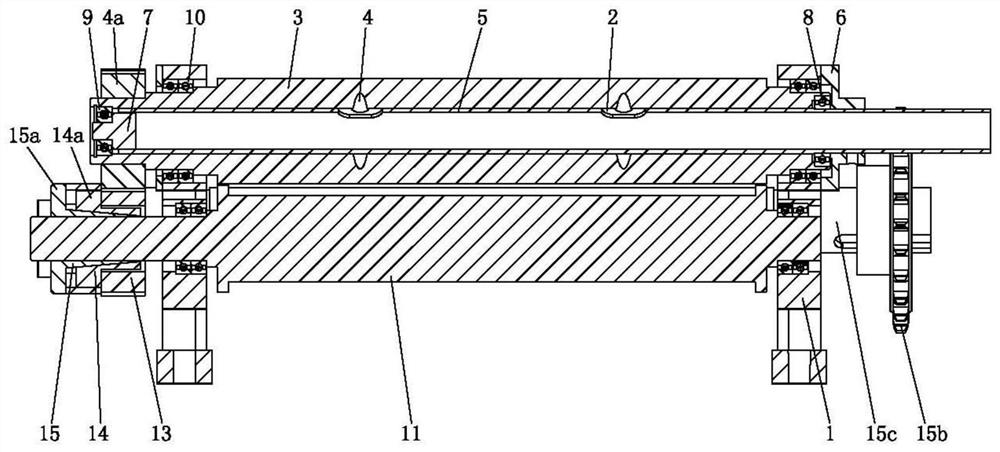

[0050] The cutting device A applies a cutting force to the introduced shoe upper fabric M, and the cutting device A includes a first mounting frame 1, a first cutter assembly, a first negative pressure mechanism that generates an adsorption force on the shoe upper fabric, and a first driver, The first negative pressure mechanism is pivotally connected with the first mounting frame, and the first negative pressure mechanism cooperates with the first cutter assembly to cut the upper material into individual upper blanks, the first driver is connected with the first cutter assembly and / or Or cooperate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com