Lumber-core board and manufacture method thereof

A blockboard and log technology, applied in the direction of manufacturing tools, wood layered products, wood processing equipment, etc., can solve the problems of high cost, poor blockboard gluing performance, difficulty in manufacturing large-format blockboard, etc., to achieve gluing high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, fir blockboard

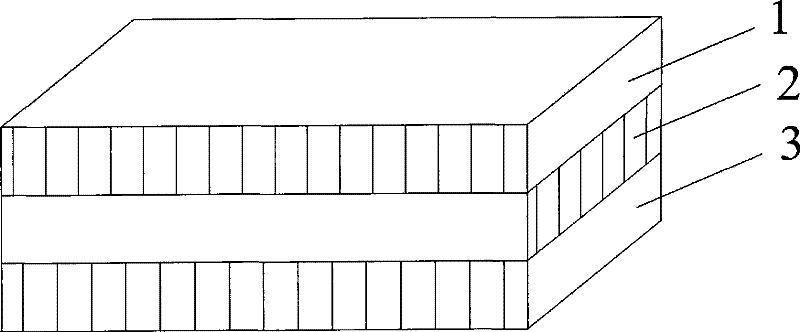

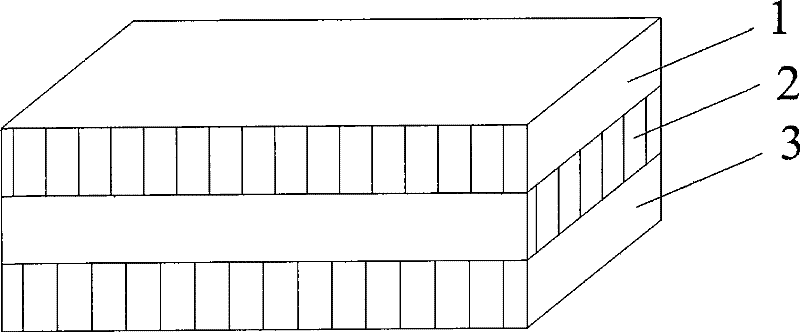

[0049] Such as figure 1 As shown, the Chinese fir blockboard provided in this example adopts three layers of Chinese fir rotary-cut thick veneer with a thickness of 4.8 mm, and is processed into a fine wood veneer after drying, gluing, billet assembly, pre-pressing, aging, and hot pressing. Woodworking board, the thickness of the processed blockboard is about 12 mm, among which, the wood grain direction of the three-layer veneer is criss-crossed and perpendicular to each other (the straight line shown in the figure shows the wood grain direction of the log rotary-cut veneer).

[0050] The specific production steps of the fir blockboard provided by the present embodiment are as follows:

[0051] 1. Sawing: Saw the Chinese fir into fir sections according to the required size;

[0052] 2. Rotary cutting: the fir wood section is rotary cut into a log rotary veneer with a thickness of 4.8 mm;

[0053] 3. Drying: Dry the rotary-cut log veneer...

Embodiment 2

[0066] Embodiment 2, masson pine blockboard

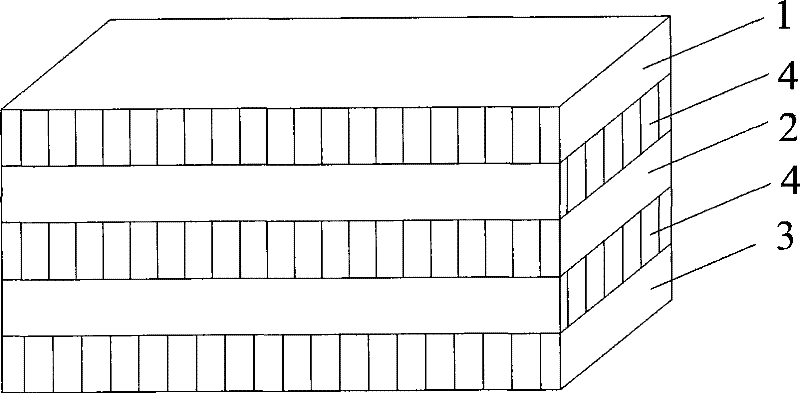

[0067] Such as figure 2 As shown, the masson pine blockboard provided in this embodiment adopts 5 layers of masson pine rotary-cut thick veneer with a thickness of 4.50 mm, and is processed through steps such as drying, gluing, forming blanks, pre-pressing, aging, and hot pressing. Blockboard, the thickness of the processed blockboard is about 18 mm, among which, the wood grain direction of the five-layer log rotary-cut veneer is criss-crossed and perpendicular to each other (the straight line shown in the figure shows the direction of the log rotary-cut veneer). wood grain direction).

[0068] The concrete production steps of the masson pine blockboard provided by the present embodiment are as follows:

[0069] 1. Sawing: Saw the masson pine into masson pine wood sections according to the required size;

[0070] 2. Rotary cutting: the masson pine wood section is rotary cut into a log rotary veneer with a thickness of 4.50 mm; ...

Embodiment 3

[0084] Embodiment 3, poplar blockboard

[0085] Such as figure 2 As shown, the poplar blockboard provided in this example uses 5 layers of poplar veneer with a thickness of 3.30 mm and is processed into a blockboard through steps such as drying, gluing, billet assembly, pre-pressing, aging, and hot pressing. , the thickness of the processed blockboard is about 12 mm, among which, the wood grain direction of the five-layer log rotary-cut veneer is criss-crossed and perpendicular to each other (the straight line shown in the figure shows the wood grain direction of the log rotary-cut veneer) .

[0086] The concrete production steps of the poplar blockboard provided by the present embodiment are as follows:

[0087] 1. Saw cutting: saw the poplar wood into poplar wood sections according to the required size;

[0088] 2. Rotary cutting: the poplar wood section is rotary cut into a log rotary veneer with a thickness of 3.30 mm;

[0089] 3. Drying: Dry the log rotary-cut veneer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com