Method for arranging non-weft band hoop on end portion of armature of brushless exciter

A no-weft belt and electromechanical technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of ineffective control of the surface temperature of the no-weft belt, the quality of the tension-free belt hoop, uneven heating of the hoop part, and production problems. Periodic impact and other issues, to achieve the effect of accurate outer circle size, solve errors, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

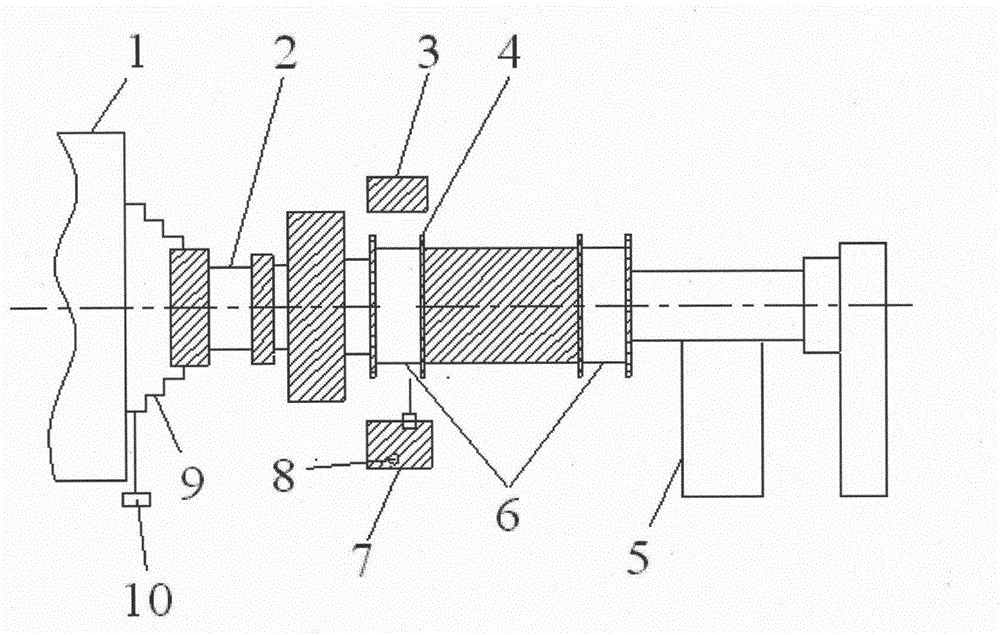

[0034] figure 1 It is a schematic diagram of a method for tying a weft-free band at the end of a brushless exciter armature provided by the present invention. The method for tying a weft-free band at the end of a brushless exciter armature consists of the following 5 steps composition:

[0035] Step 1: The rotating shaft is hoisted to the hooping machine, and the hooping tool is in place:

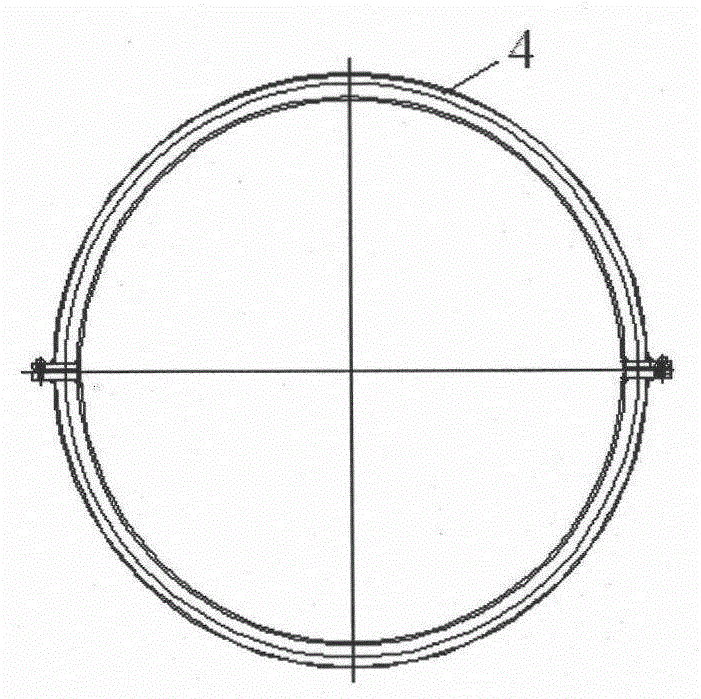

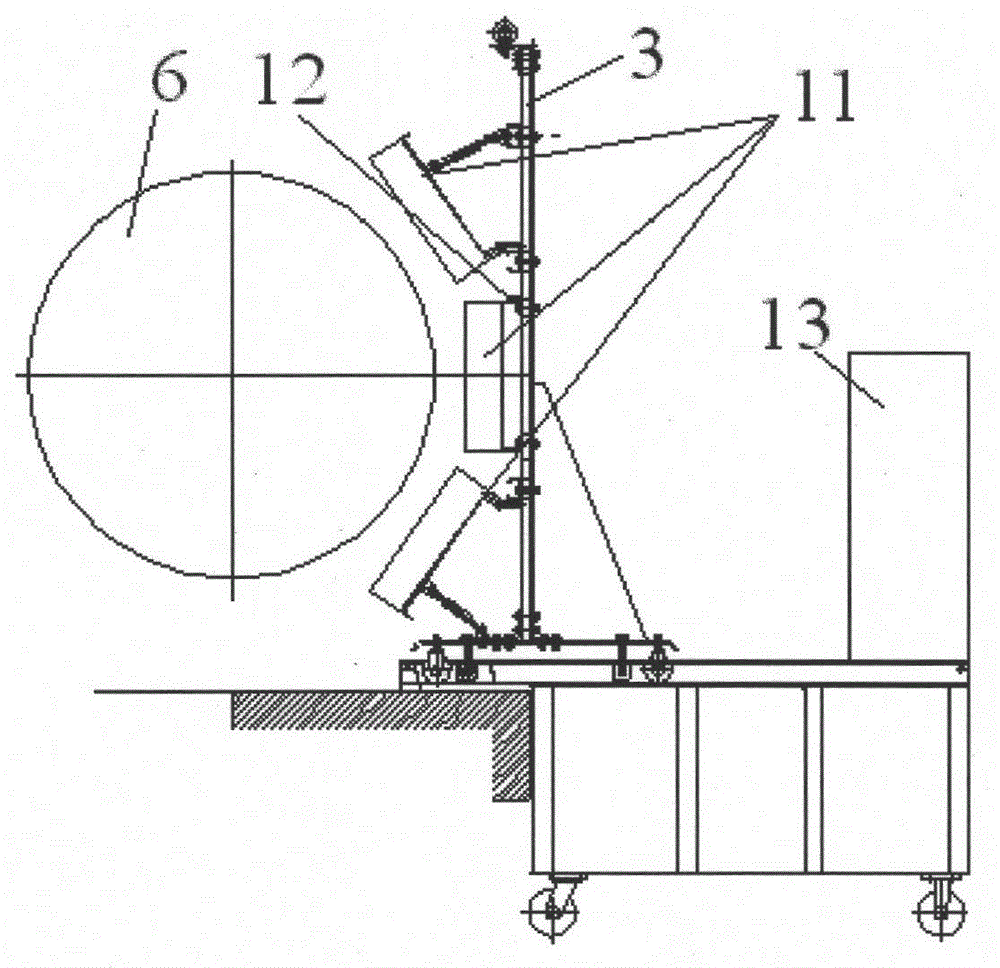

[0036] Clamp the two ends of the hoop part 6 at both ends of the armature respectively figure 2 The shown hoop clamp 4 with size limit line lifts the exciter rotor 2 to the hoop machine tool 1, and supports the center frame 5 at the bearing gear. Place the heater 3 and the hoop tension device 7 on both sides of the hoop site 6 respectively. to combine image 3 , the heater 3 includes three heating plates 11, and the heating plates 11 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com