Grinding device used for machining mechanical sealing elements

A technology for mechanical seals and workpieces, which is applied in the direction of grinding drive devices, metal processing equipment, and parts of grinding machine tools, etc. It can solve the problems that the workpiece cannot be turned over, the workpiece cannot be clamped, and the distance between the grinding head and the workpiece cannot be adjusted. Achieve the effect of increasing the grinding area and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0020] The purpose of this application is to provide a grinding device for mechanical seal processing to solve the problems raised in the above background.

[0021] In order to achieve the above object, the present application provides the following technical solutions include:

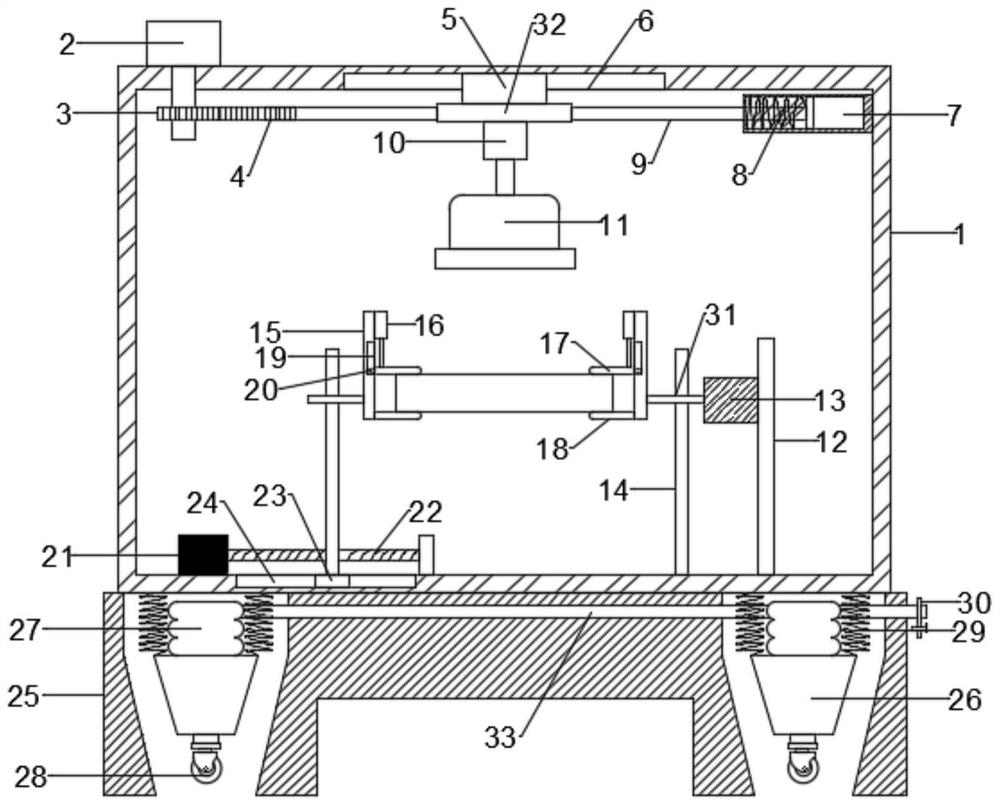

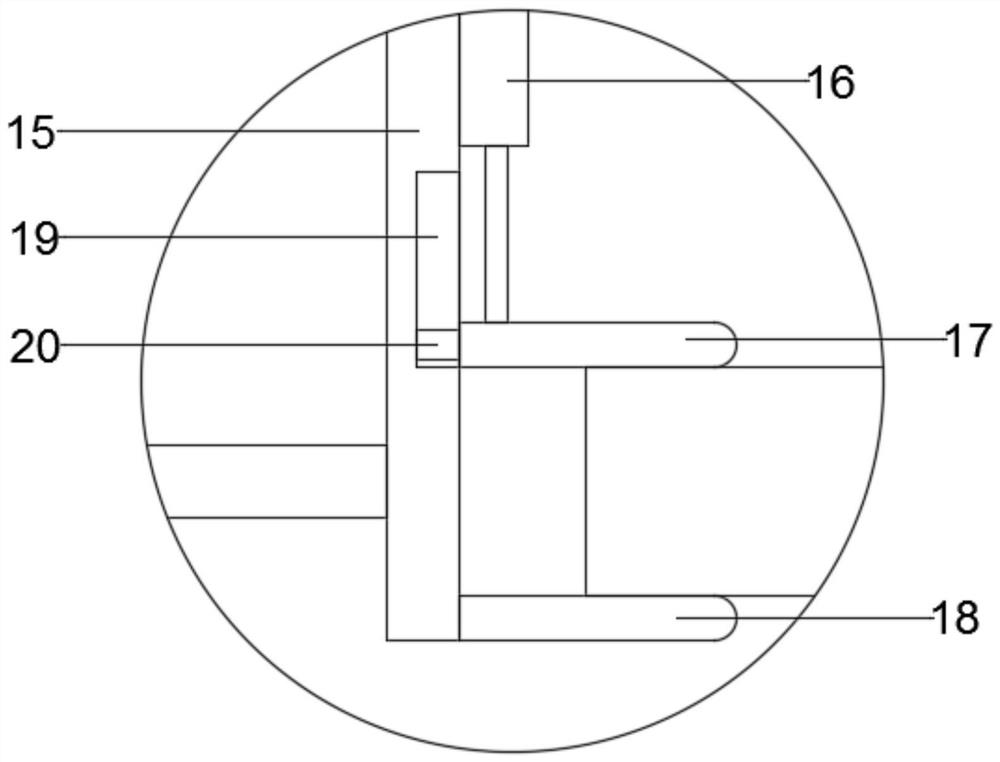

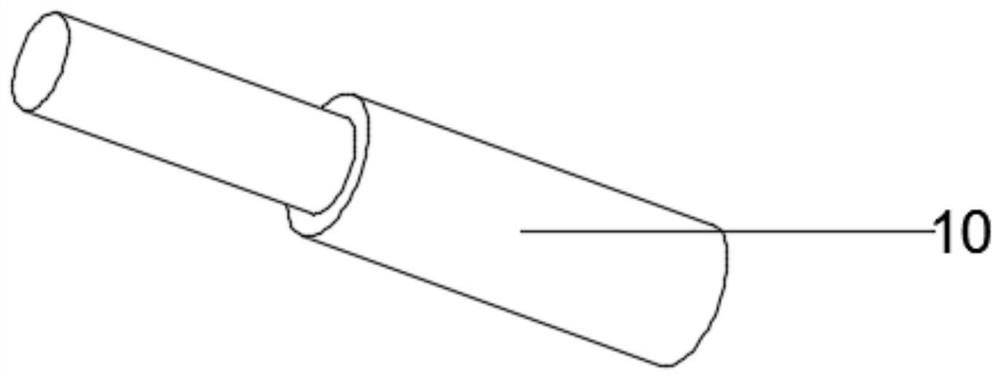

[0022] A grinding device for mechanical seal processing, including the apparatus body, further comprising an adjustment member, fixed to the top of the apparatus main body, for connecting the grinding member; the wear member, secured to the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com