Countersunk head structure with non-molten clamping piece and knife body

A kind of knife meat and clip technology, which is applied in metal processing and other directions, can solve the problem of non-melting, achieve the effect of convenient use, increase the use function, and prevent accidental loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

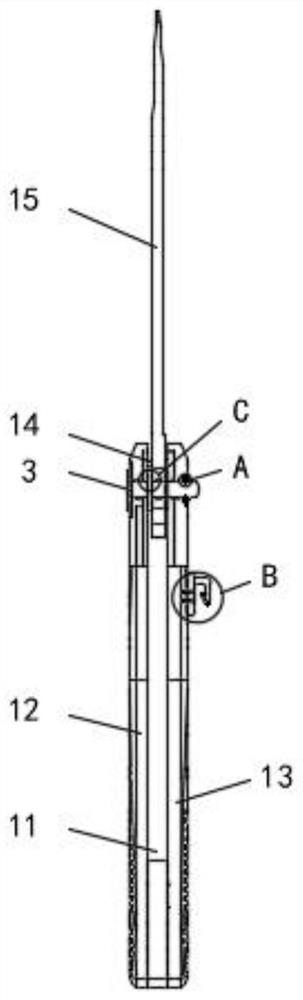

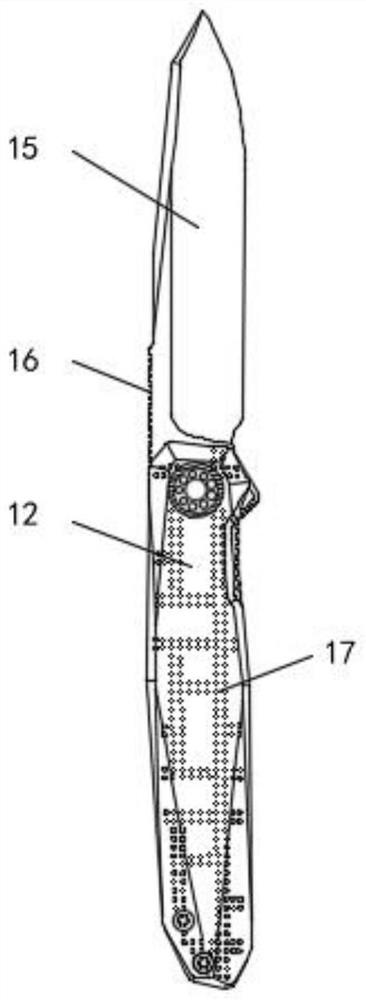

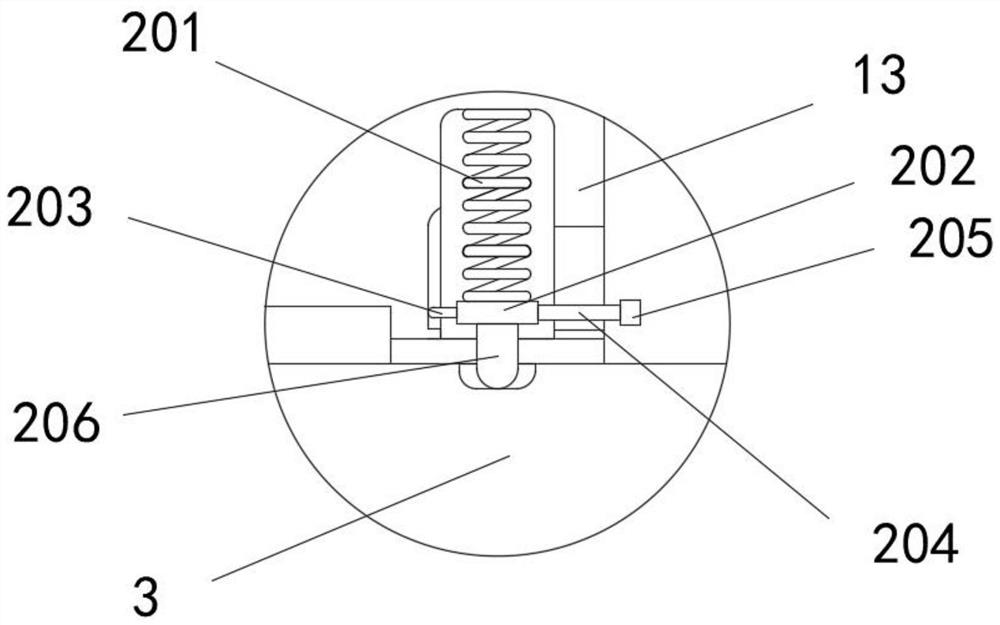

[0027] see Figure 1-6 , the clip and the knife meat in this embodiment do not have a countersunk structure, including a cutter main structure 10, an auxiliary structure 200 and a fixed rod 3, the cutter main structure 10 is located outside the fixed rod 3, and the auxiliary structure 200 is located in the cutter main structure The right side of 10, wherein, the tool body structure 10 is convenient for the operator to use, and ensures the safety of the user, prevents accidents, has a simple structure, beautiful appearance, meets modern aesthetic requirements, and also conforms to usage habits, is convenient to hold, and can For better operation and use, the auxiliary structure 200 adds the auxiliary function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com