Circulating type cooling tank for plastic tube injection molding

A technology of injection molding and cooling tank, which is applied in applications, tubular objects, household appliances, etc., can solve the problems of low utilization rate of cooling liquid and low cooling efficiency, and achieve the effect of improving cooling efficiency and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

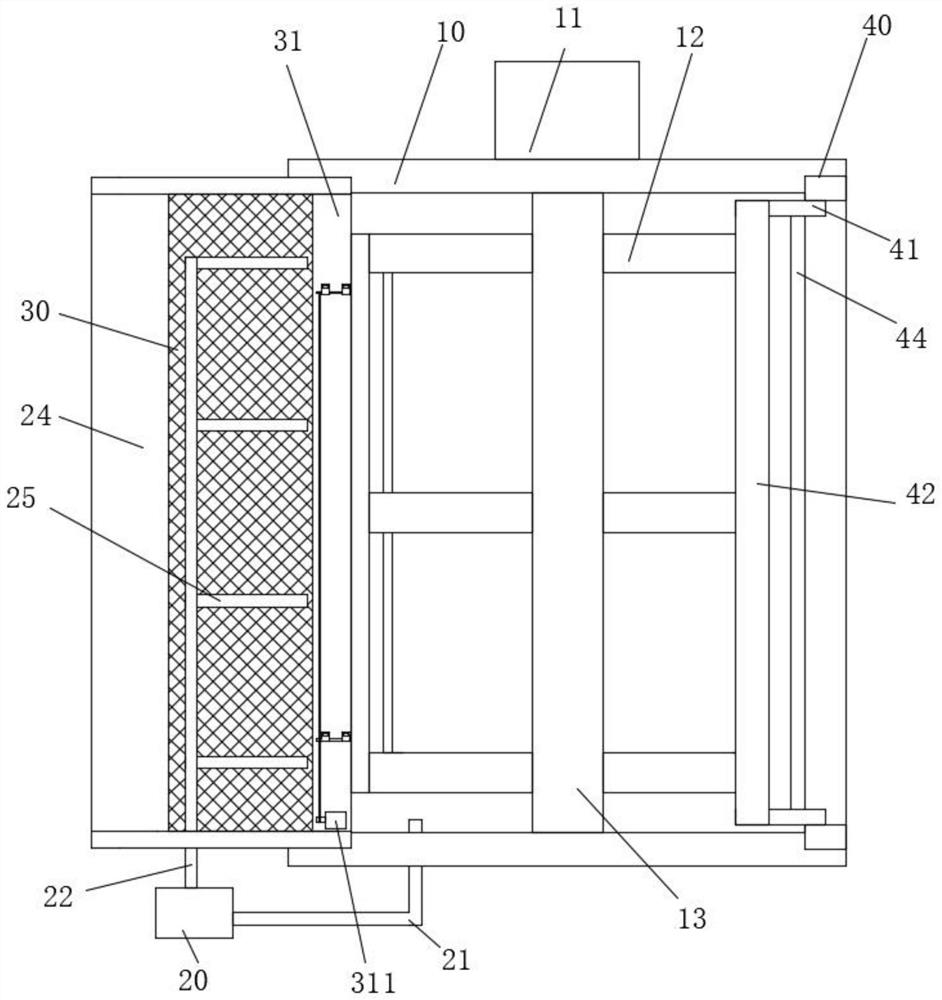

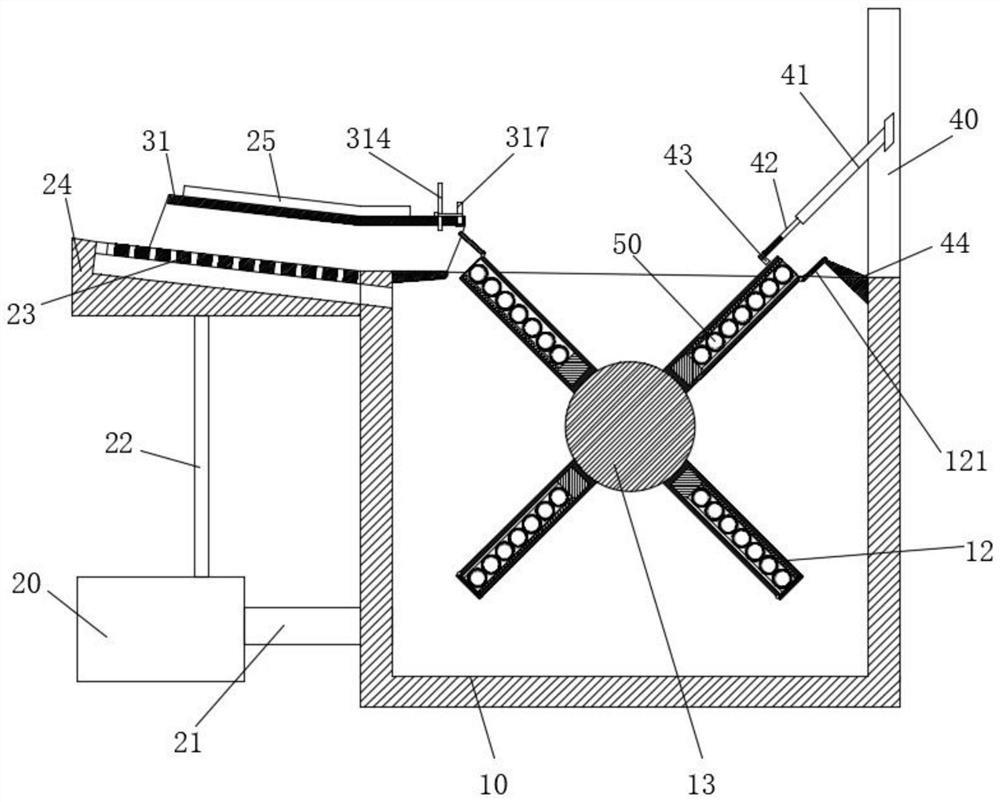

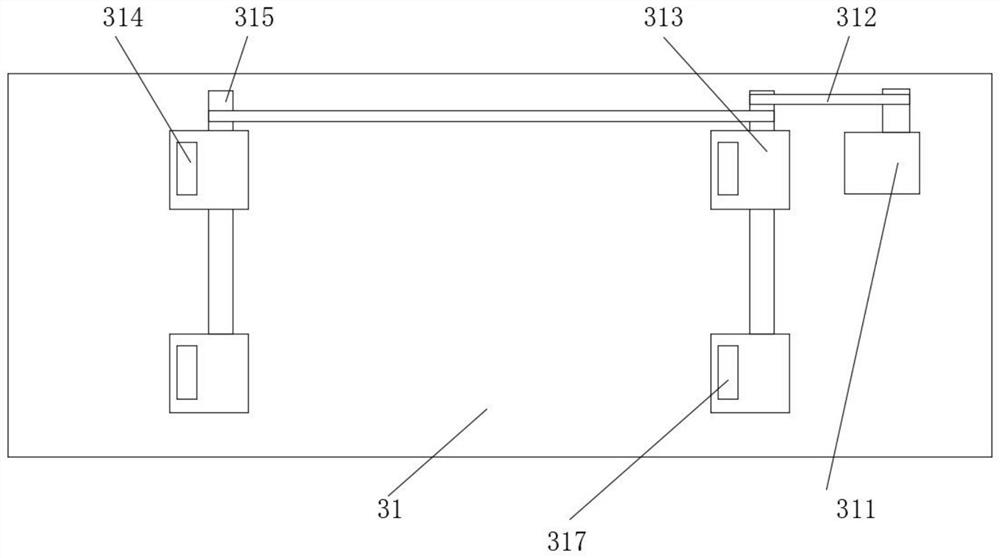

[0035] see Figure 1-9 , a circulating cooling tank for plastic pipe injection molding, including a cooling tank 10, a rotatable circulation shaft 13 is provided in the middle of the cooling tank 10, and multiple groups of fixed connections are provided on the circulation shaft 13 and are used for pipe body Fixed cooling frame 12, each group of cooling frames 12 is multiple, and cooling frame 12 is provided with a fixed groove 124 for tube body storage, the upper end of the fixed groove 124 is provided with openable and closed and used to prevent The sealing plate 121 that the pipe body drops.

[0036]The rotation of the circulating shaft 13 drives the cooling frame 12 to rotate periodically in the cooling tank 10, thereby realizing the rotation of the pipe body in the cooling tank 10, so that the pipe body can fully contact and cool with the cooling liquid at different positions in the cooling tank 10 , which improves the overall cooling efficiency; and the rotation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com