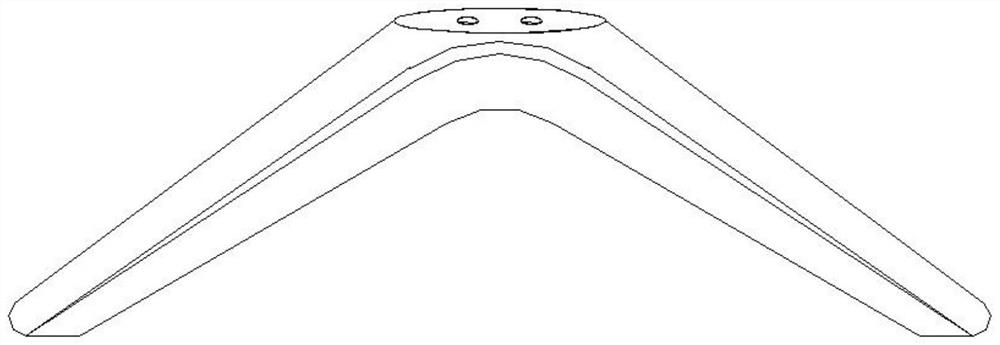

Blow molding product with high surface smoothness and manufacturing device

A technology for blow molding products and manufacturing devices, which is applied in the field of blow molding products and manufacturing devices with high surface finish, and can solve problems such as the limitation of the use range of devices, and achieve the goal of improving production value, improving production effect, and ensuring continuity and effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

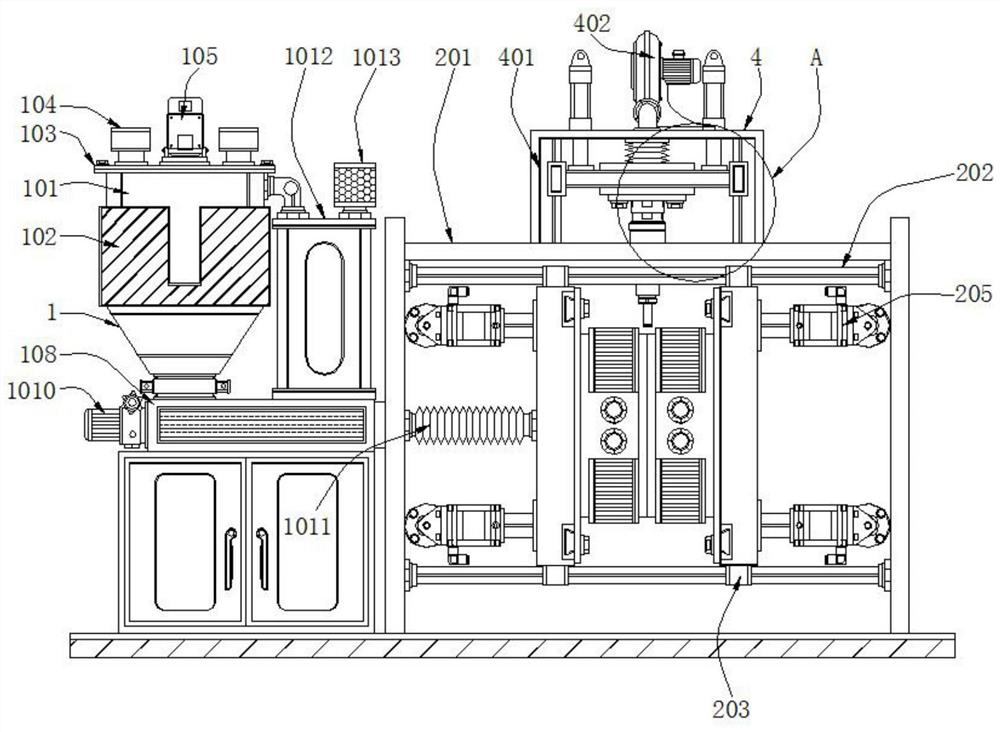

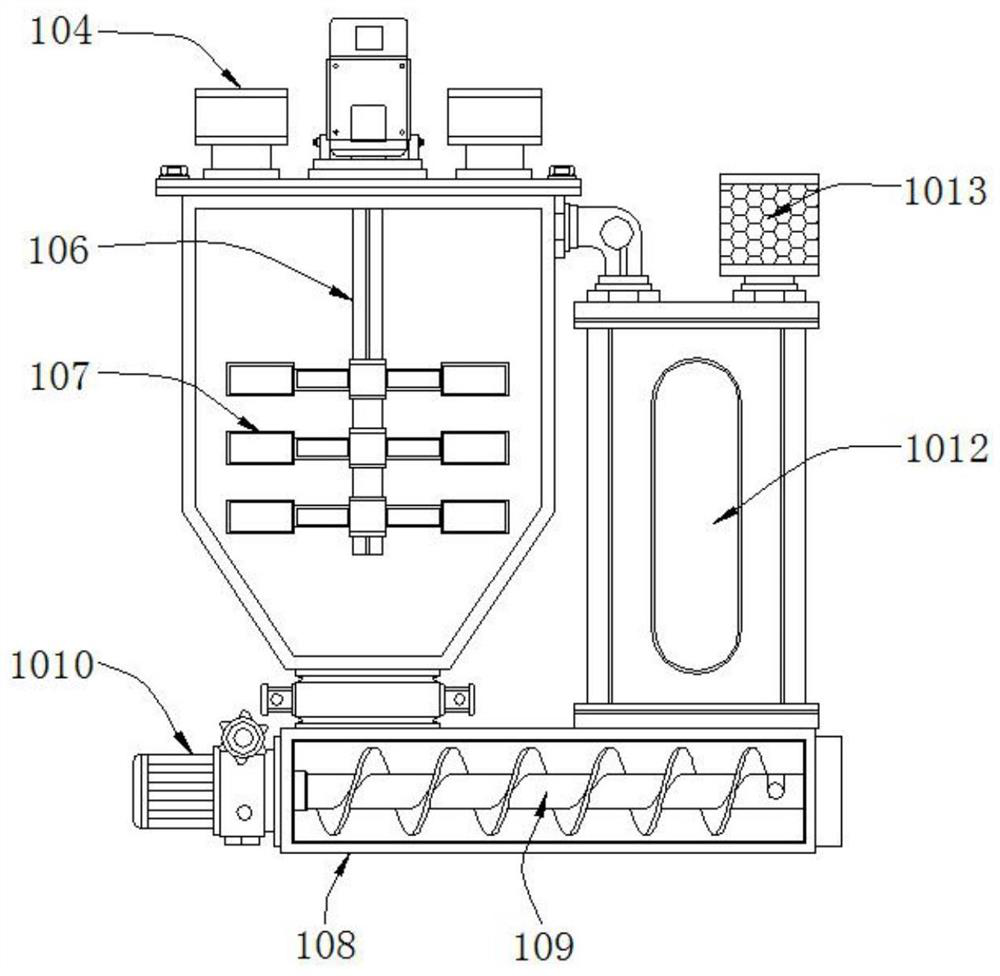

[0028] see Figure 1-6 , a high surface finish blow molding product and manufacturing device, including a mixing assembly 1 and a blow molding assembly 4, the right side of the mixing assembly 1 is provided with a driving assembly 2, and the middle part of the driving assembly 2 is connected to a molding assembly 3, the molding assembly 3 includes a placement chute 301, a placement slider 302, a molding module 303, a positioning bolt 304, a heating block 305 and a cooling water pipe 306, and the inside of the placement chute 301 is connected with a placement slider 302, and the other side of the placement slider 302 The forming module 303 is connected, and the inner side of the sliding block 302 is provided with positioning bolts 304, the two sides of the forming module 303 are provided with heating blocks 305, and the inside of the forming module 303 is provided with a cooling water pipe 306, and the blow molding assembly 4 is arranged on the upper end of the drive assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com