Die cutting machine for food packaging carton production

A food packaging and die-cutting machine technology, applied in the directions of packaging, transportation and packaging, papermaking, etc., can solve the problems of reducing the efficiency of cardboard die-cutting, equipment jams, scrapping, etc. The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

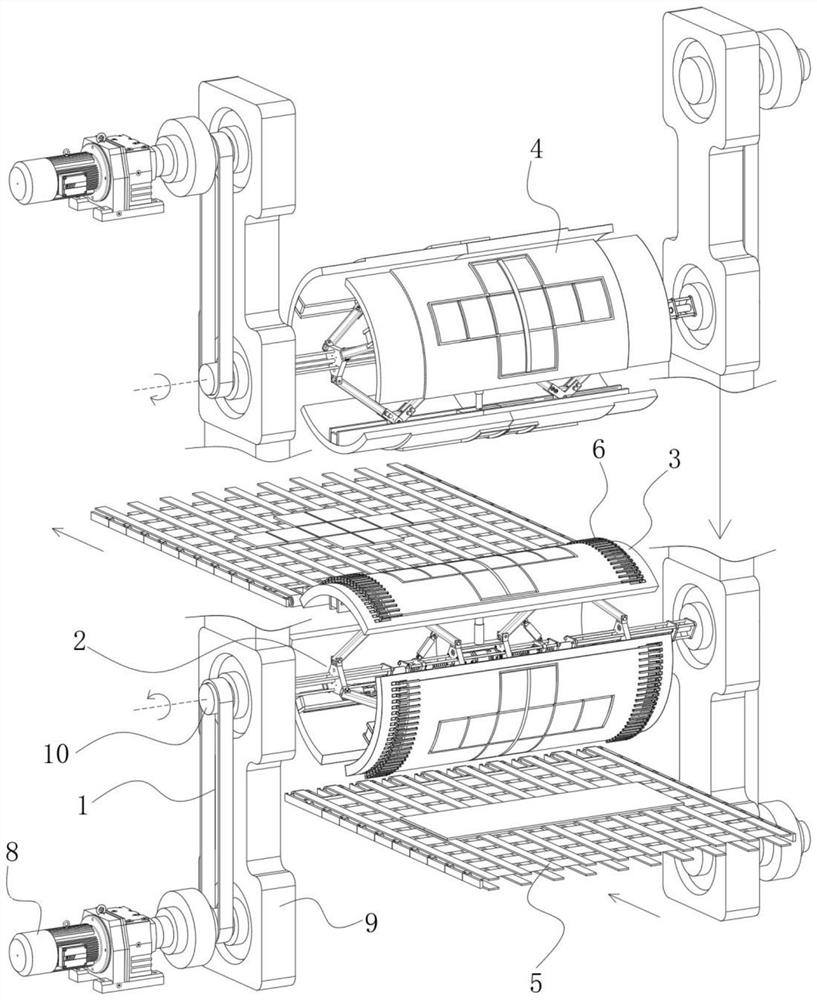

[0032] refer to Figure 1-4 , the present invention provides a technical solution: a die-cutting machine for food packaging carton production, which includes:

[0033] The driving device 1 is provided with two groups, and is symmetrically arranged up and down;

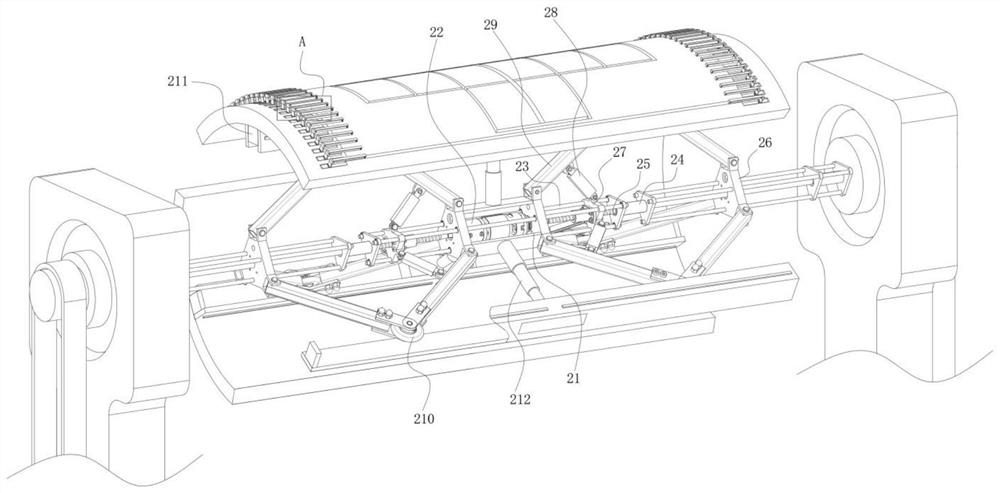

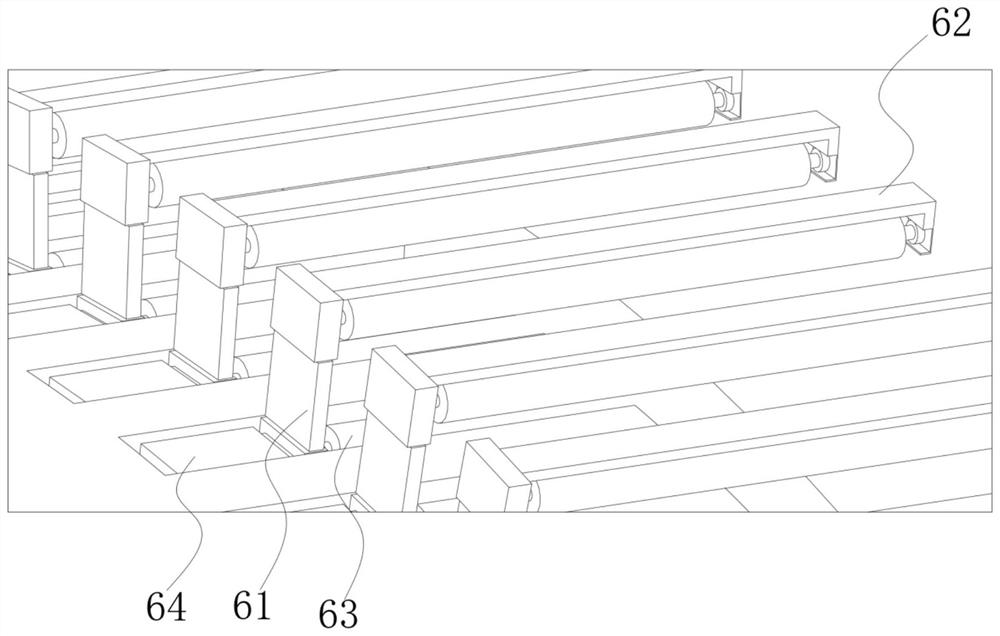

[0034] The rolling support 2 is in a cylindrical structure, and two groups are provided, which are respectively installed in the driving device 1 above and below. The die-cutting embossing plate 4 is installed on the outer side of the rolling support above, and the outer side of the rolling support below is installed. There are fixed templates 3, all of which are circular arc plate structures, with a central angle of 90°, and a clamping assembly 6 is installed near the left and right side arc edges of the fixed template 3, and an elastic pusher 7 is installed inside the fixed template, and Multiple groups are arranged along the arc surface, and the central angle is set at 90°, which can ensure that the arc surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com