Leaf storage cabinet and self-diagnosis control method thereof

A technology for leaf storage cabinets and cabinets, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., which can solve the problems of deformation of the position detection rod of the horizontal distribution vehicle, shutdown of the process section, equipment stampede events, etc., to prevent horizontal distribution The effect of reducing vehicle failure, reducing failure points, and reducing the amount of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

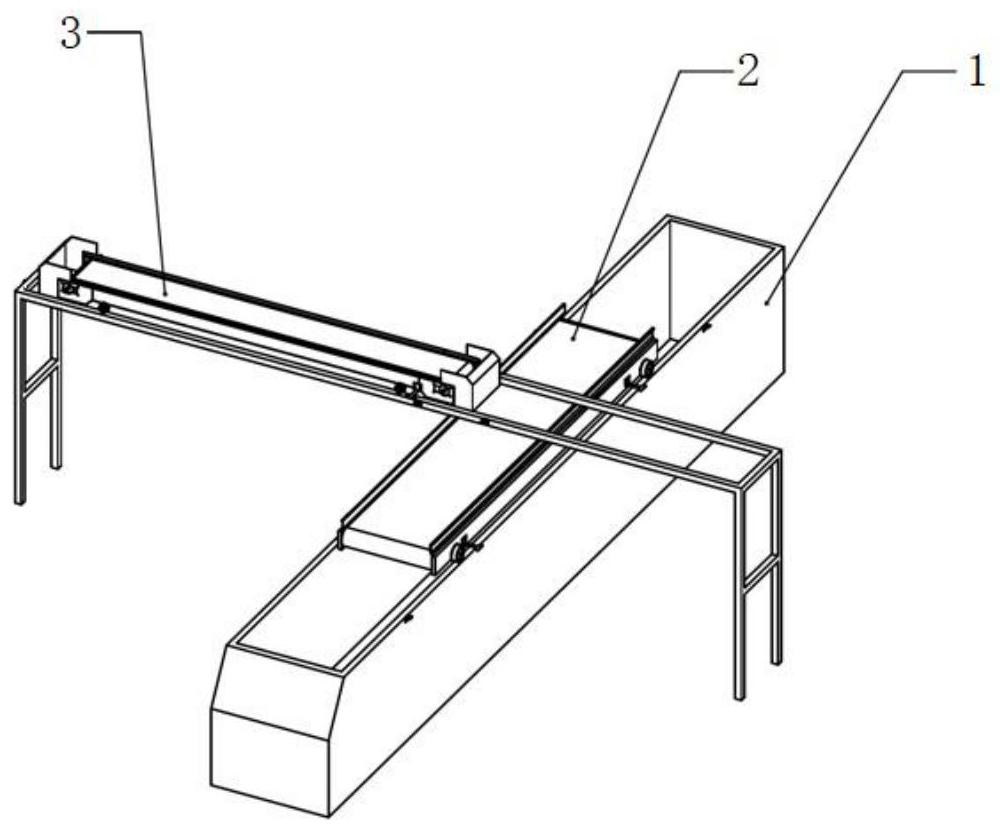

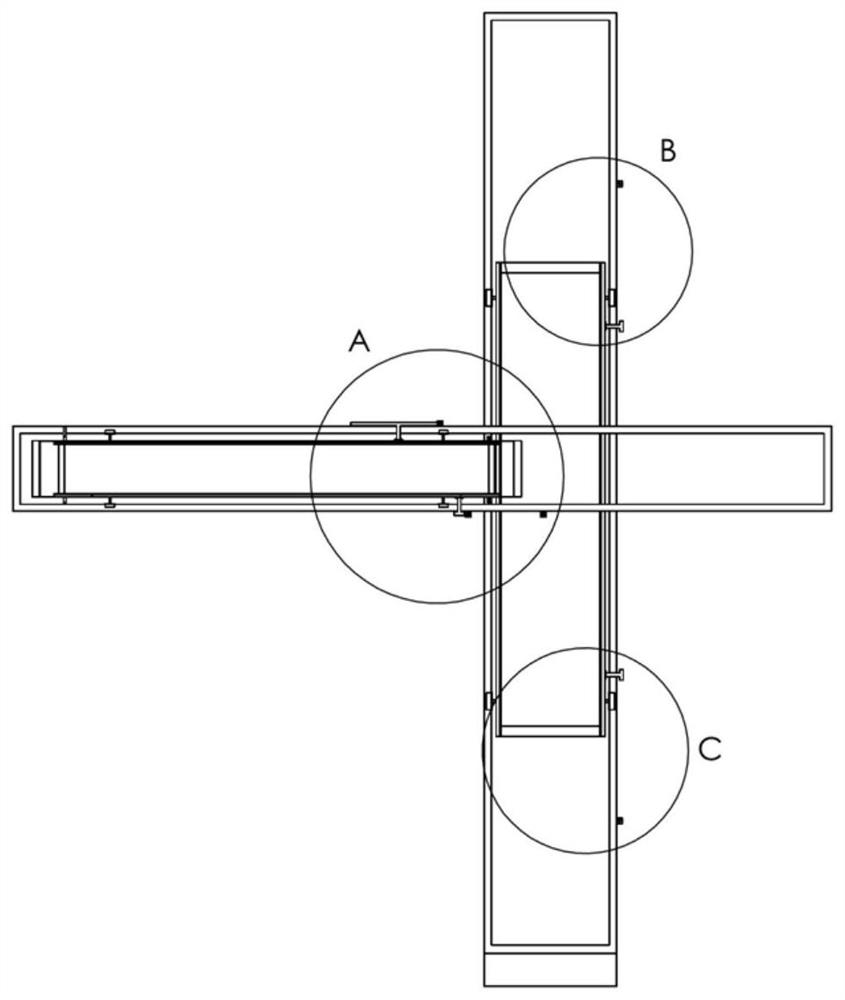

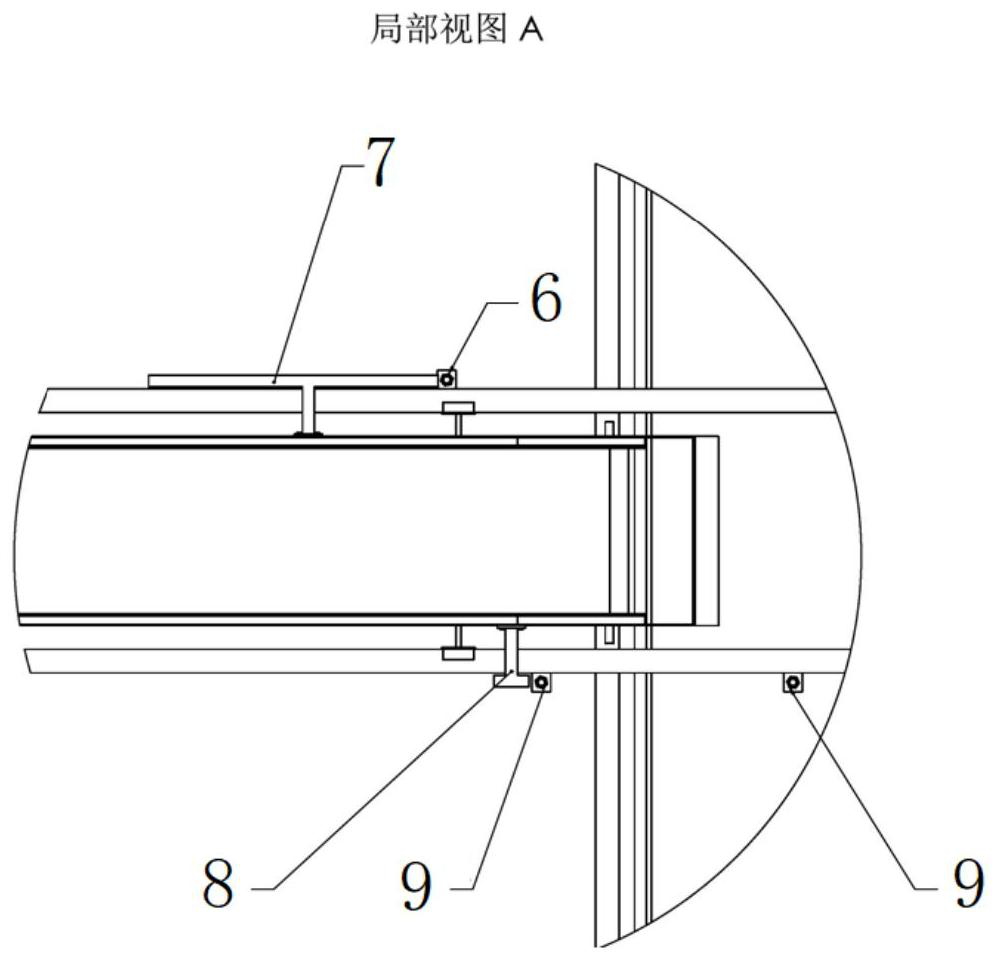

[0029] Such as Figure 6-Figure 10 As shown, a leaf storage cabinet includes a cabinet body 1, a material spreading vehicle 2 and a horizontal material distribution vehicle 3, the material spreading vehicle 2 is arranged on the cabinet body 1, and both ends of the material spreading vehicle 2 are provided with paving The limit detection rod 4 of the material spreading vehicle, the two ends of the cabinet body 1 are provided with the limit proximity switch 5 of the material spreading vehicle, through the limit detection rod 4 of the material spreading vehicle and the limit proximity switch 5 of the material spreading vehicle, the Material trolley 2 reciprocating continuous material distribution is used to vertically lay materials in the cabinet 1; the horizontal material distribution vehicle 3 is set above the material laying vehicle 2 through the support frame 10, and the horizontal material distribution vehicle 3 Arranged orthogonally to the material spreading vehicle 2, a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com