A gasification method and system with fly ash regasification

A technology for regasification and gasification of coal gas, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve problems such as difficult disposal, environmental pollution, and large production of gasification fly ash The effect of reducing equipment investment and enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

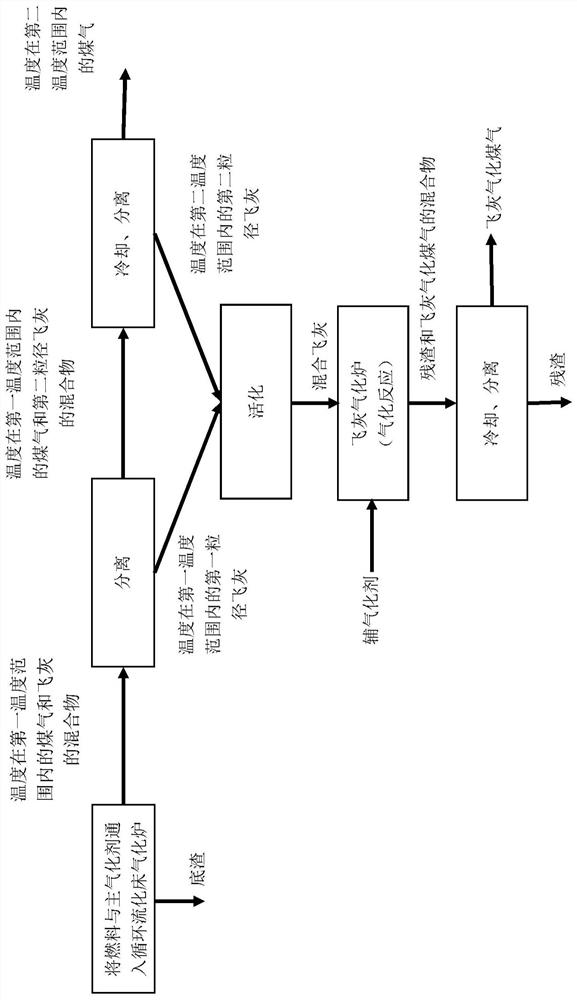

[0081] The invention provides a gasification method with fly ash regasification, figure 1 It is a system flow chart of a gasification method with fly ash regasification provided according to an embodiment of the present invention, such as figure 1 As shown, the method specifically includes:

[0082] (1) Passing the fuel and the main gasification agent into the circulating fluidized bed gasifier for gasification reaction to generate primary products; the reaction temperature of the circulating fluidized bed gasifier is between 850°C and 1200°C, specifically, During the operation of the gasifier, the maximum temperature at the bottom of the furnace is controlled to be 50-150°C lower than the softening temperature of the fuel ash in a weak reducing atmosphere to avoid over-temperature slagging at the bottom of the furnace. The fuel ash refers to the residue left after the fuel is completely burned and gasified.

[0083] The above-mentioned fuels are all solid fuels that can be ...

Embodiment 2

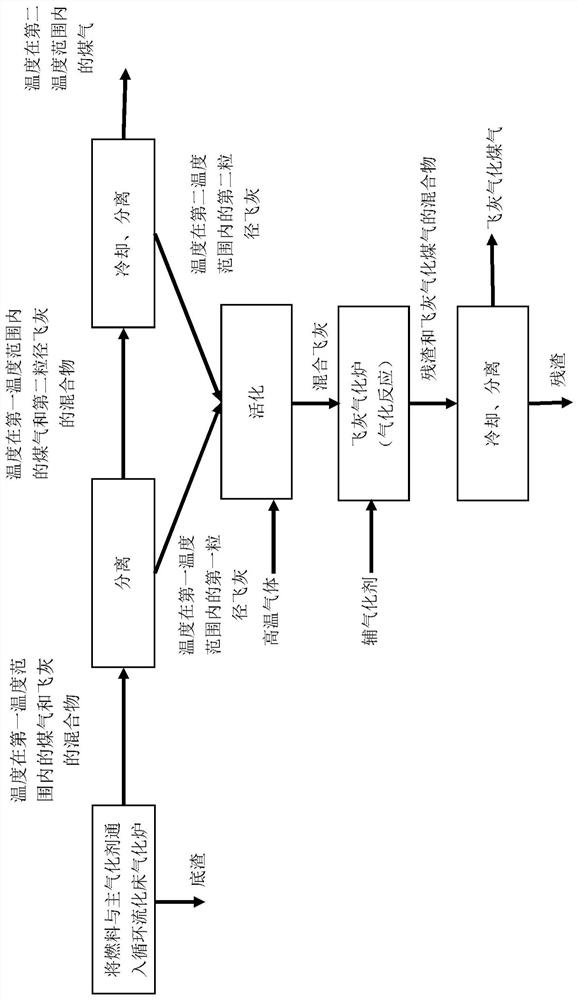

[0095] figure 2 It is a system flow chart of a gasification method with fly ash regasification provided according to another embodiment of the present invention, such as figure 2 As shown, this method is roughly the same as figure 1 The method shown is the same except that:

[0096] The first particle size fly ash with a temperature within the first temperature range, the auxiliary gasification agent, and the second particle size fly ash with a temperature within the second temperature range are passed into the fly ash gasifier to carry out gasification reaction. In the ash activator, the high temperature gas is introduced while the activation reaction is carried out, that is, the first particle size fly ash whose temperature is in the first temperature range, the second particle size fly ash whose temperature is in the second temperature range, and the high temperature gas are introduced into the ash activator. A fly ash activator, so that in the fly ash activator, a high...

Embodiment 3

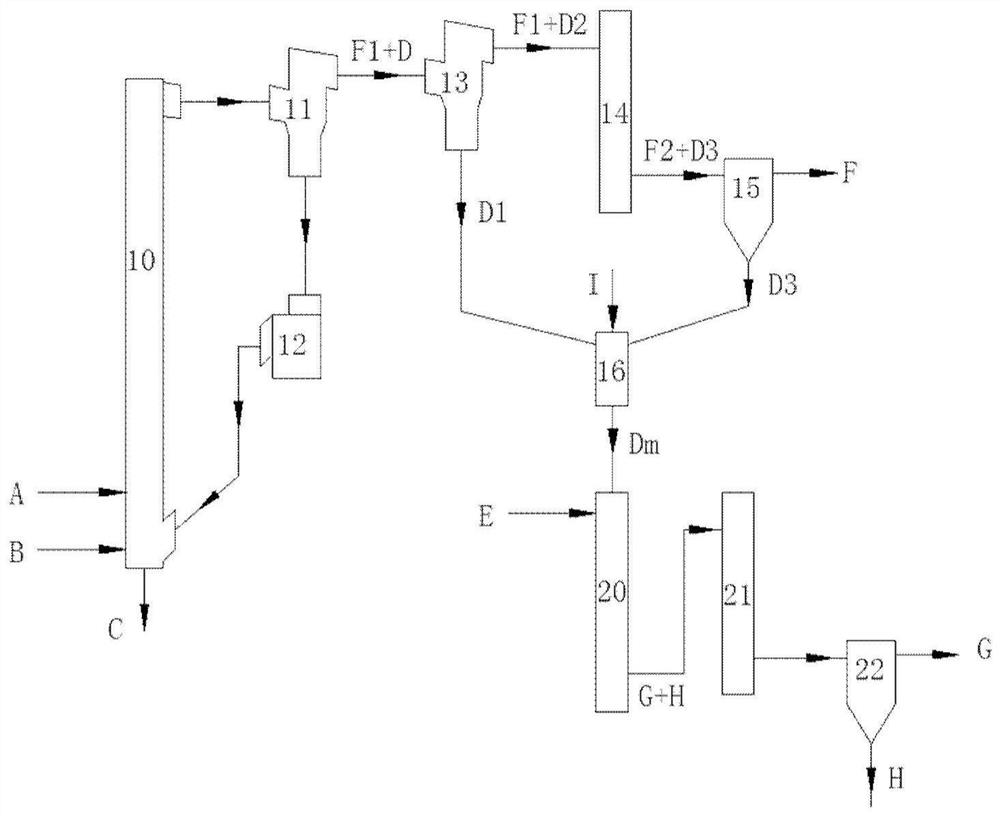

[0101] The gasification method with fly ash regasification of the present invention specifically includes:

[0102] (1) pass fuel and main gasification agent into circulating fluidized bed gasifier to carry out gasification reaction to generate primary product;

[0103] (2) Passing the primary product into the first-stage gas-solid separation device to generate a mixture of coal gas and fly ash and carbon-containing particles with a temperature within the first temperature range, and returning the carbon-containing particles to the circulating fluidized bed through a return device gasifier;

[0104] (3) the mixture of coal gas and fly ash whose temperature is in the first temperature range is passed into the secondary gas-solid separation device for separation, and the first particle size fly ash whose temperature is in the first temperature range is obtained; also obtain the temperature in the second A mixture of coal gas and fly ash of a second particle size within a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com