Quick exhaust valve with overpressure protection function

A technology of overpressure protection and exhaust valve, applied in the direction of functional valve type, valve details, multi-way valve, etc., can solve the problems of inconvenient pipeline connection, large occupied volume, and many pneumatic components, so as to enhance the reliability of long-term use , Easy to disassemble and replace, avoiding the effect of contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

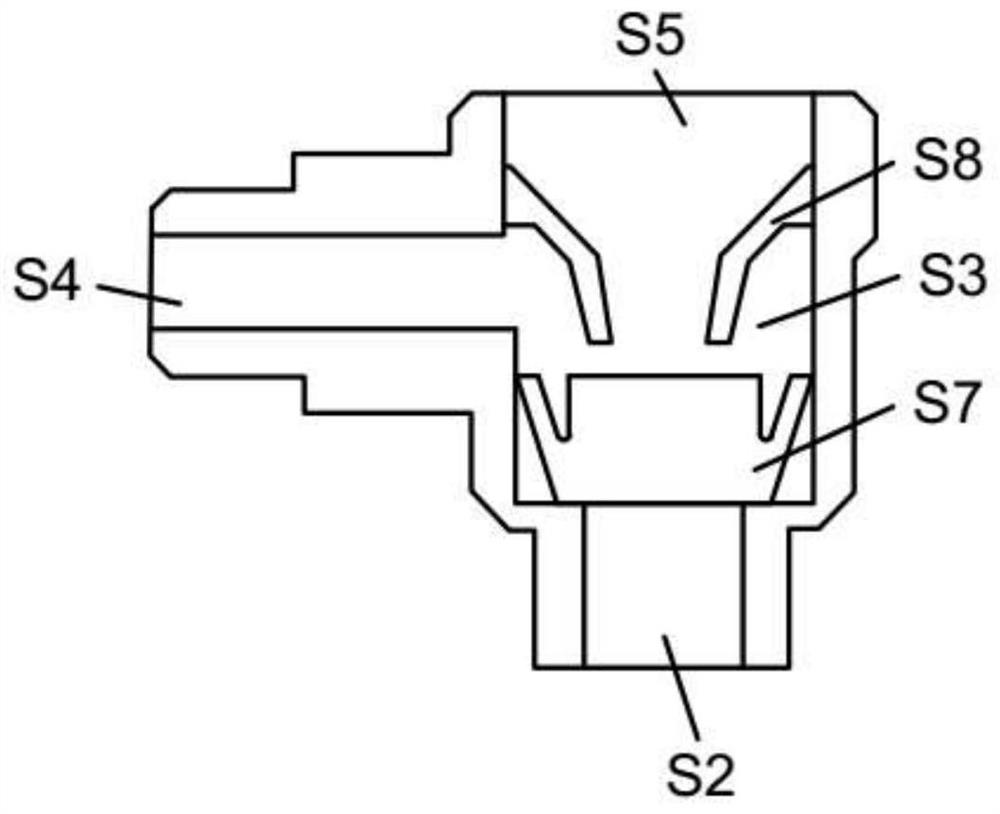

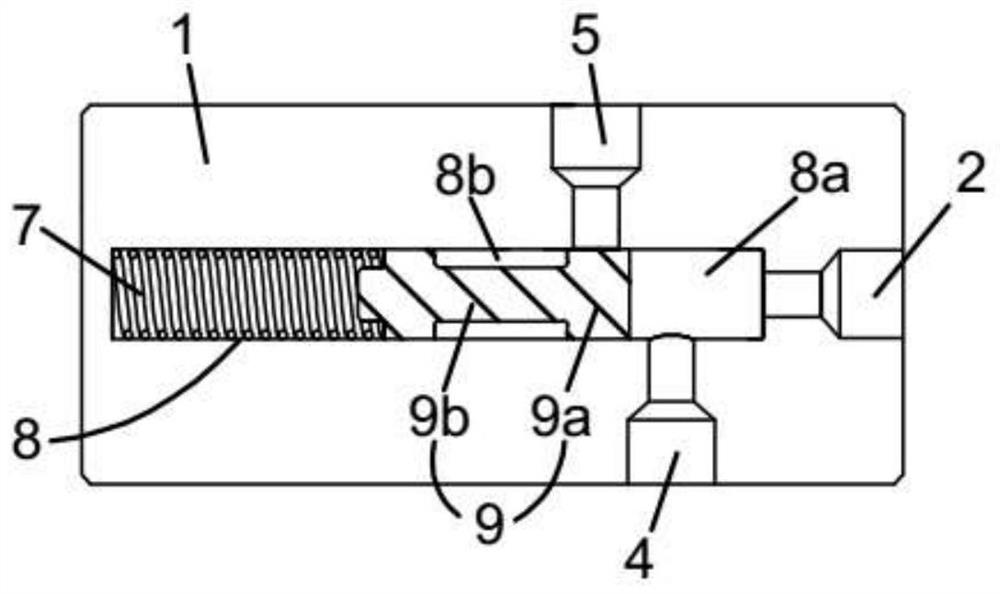

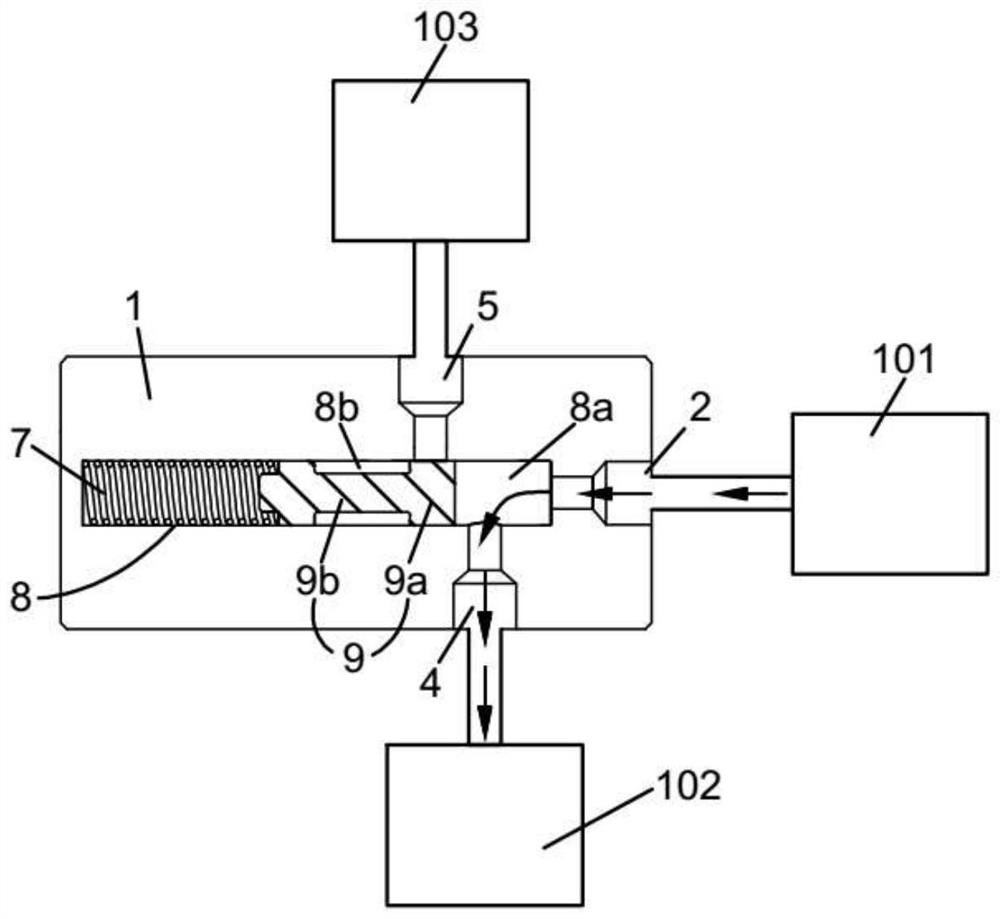

[0035] Such as figure 2 As shown, this embodiment provides a quick exhaust valve with an overpressure protection function, including a valve body 1, the valve body 1 has three valve ports and a valve cavity 8, and the three valve ports are respectively the first valve port 2. The second valve port 4 and the third valve port 5; the first valve port 2 communicates with the air source 101 outside the quick exhaust valve, and the second valve port 4 communicates with the actuator 102 outside the quick exhaust valve. The third valve port 5 is connected with the discharge environment 103 outside the quick exhaust valve.

[0036]A reversing mechanism is provided in the valve cavity 8, the reversing mechanism includes a spring 7 and a valve core 9, the spring 7 is located between one end of the valve core 9 and the wall of the valve cavity 8, the valve core 9 can reciprocate in the valve cavity 8; The spool 9 divides the valve cavity 8 into at least two mutually isolated first chamb...

Embodiment 2

[0045] Figure 6 Another embodiment of the quick exhaust valve shown in the present invention is shown. The difference between this embodiment and Embodiment 1 is that the valve body 1 has four valve ports, and the fourth valve port 6 is arranged on the third Near the valve port 5, more preferably, the fourth valve port 6 and the third valve port 5 are coaxially arranged, and the flow path between the two is basically linear; the second valve port 4 and the fourth valve port 6 are connected to the The actuator 102 outside the quick exhaust valve is connected, the gas enters the actuator 102 through the second valve port 4 , and the gas to be discharged in the actuator 102 is discharged outside through the fourth valve port 6 .

[0046] Figure 7-9 The working principle of the quick exhaust valve described in this embodiment under different gas pressure states is shown:

[0047] Such as Figure 7 As shown, when the intake pressure is higher than the opening pressure and lowe...

Embodiment 3

[0053] Figure 10 Another embodiment of the quick exhaust valve shown in the present invention is shown. The difference between this embodiment and Embodiment 1 or 2 is that a valve sleeve 12 is fixedly installed in the valve cavity 8 of the valve body 1, and the valve sleeve 12 It is made of high wear-resistant and self-lubricating materials such as ceramics or PTFE; the outer side of the valve sleeve 12 and the inner side of the valve cavity 8 can be respectively provided with external threads and internal threads, and the valve sleeve 12 is installed in the valve cavity 8 through threaded connections .

[0054] The valve sleeve 12 is provided with openings corresponding to the first valve port 2, the second valve port 4, the third valve port 5 and the fourth valve port 6 respectively, and a reversing mechanism is provided in the valve sleeve 12, and the reversing mechanism includes Spring 7 and spool 9, one side of spring 7 is connected with the inner side wall of valve sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com