Model simulation method for liquid nitrogen flow in corrugated pipe of high-temperature superconducting cable

A cable corrugation and high-temperature superconducting technology, which is applied in design optimization/simulation, electrical digital data processing, CAD numerical modeling, etc., can solve the problems of simulation accuracy and low reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

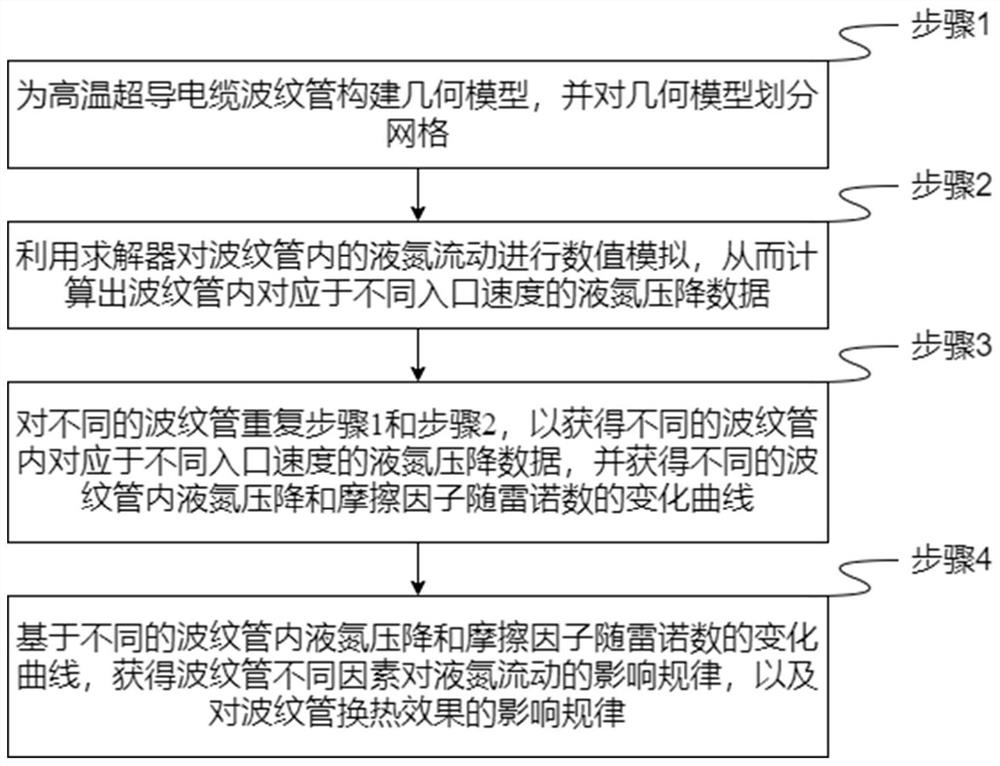

[0047] figure 1 It is a schematic flowchart of steps in a model simulation method for liquid nitrogen flow in a high temperature superconducting cable bellows of the present invention. Such as figure 1 As shown, a model simulation method for liquid nitrogen flow in a high temperature superconducting cable bellows is characterized in that it includes steps 1-4.

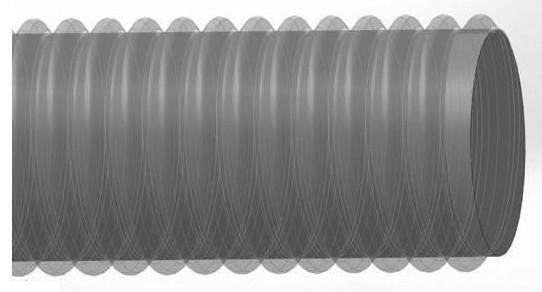

[0048] Step 1. Construct a geometric model for the high-temperature superconducting cable bellows, and divide the geometric model into meshes.

[0049] Preferably, the geometric model of the high-temperature superconducting cable bellows includes a central spiral pipe section and straight pipe sections at both ends; dividing the grid inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com