Method and device for screening sensors in industrial manufacturing, terminal equipment and storage medium

A technology of industrial manufacturing and screening methods, applied in the field of industrial manufacturing, can solve problems such as time-consuming and energy-consuming, sensor omission, affecting the performance of FDC models, etc., to achieve the effect of improving performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

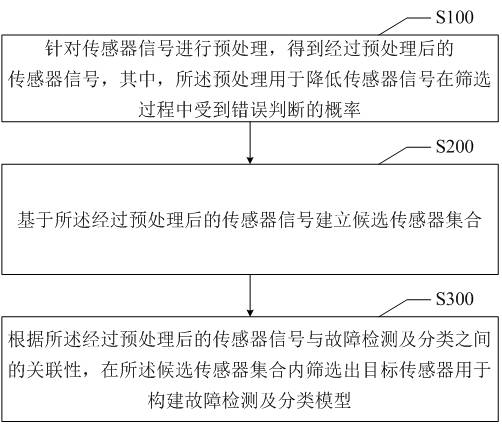

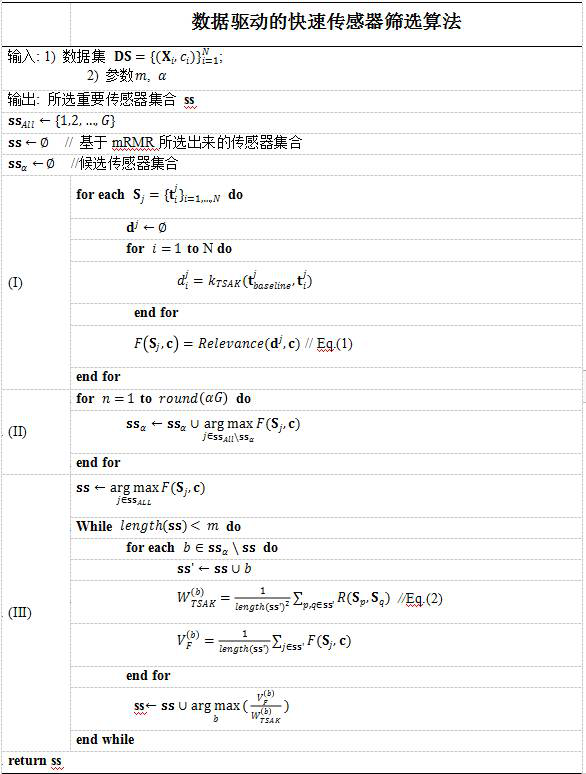

[0079] The first embodiment: please refer to figure 2 and image 3 , figure 2 It is a schematic flow chart of the first embodiment of the screening method for sensors in industrial manufacturing of the present invention, image 3 It is an algorithm coding diagram of an embodiment of a sensor screening method in industrial manufacturing of the present invention. The screening method of sensor in the industrial manufacturing provided by the invention, comprises the following steps:

[0080] In step S100, preprocessing is performed on the sensor signal to obtain the preprocessed sensor signal, wherein the preprocessing is used to reduce the probability that the sensor signal is misjudged during the screening process.

[0081] It should be noted that, in this implementation, since the process of screening sensors is realized by analyzing and evaluating the sensor signals, before analyzing and evaluating the sensor signals, it is necessary to preprocess the sensor signals to i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap