Radiation hole design method of thermal radiation component and thermal radiation component

A technology of heat radiation components and design methods, which is applied to heating elements, ohmic resistance heating components, etc., can solve the problems of inability to achieve uniform heating and difficulty in uniform heating, and achieve the effect of increasing radiation amount and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

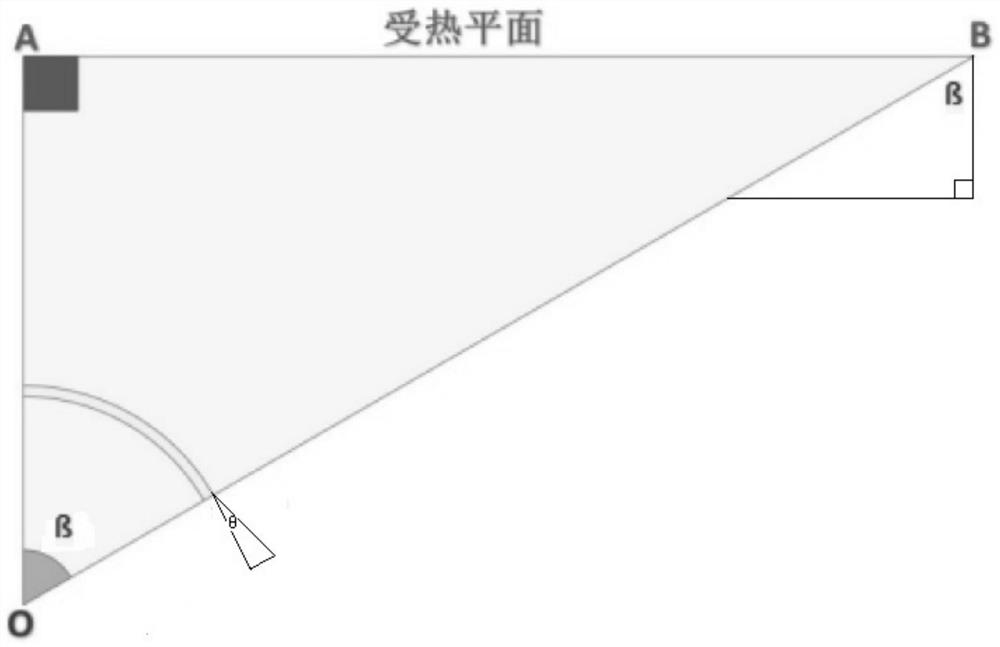

[0050] see figure 1 The schematic diagram of the design principle of the radiation hole of the heat radiation component is shown. Embodiment 1 of the present application discloses a design method of the radiation hole of the heat radiation component. The design method includes the following steps:

[0051] Step 1, mark the thermal radiation source with a point O, and mark the heated plane corresponding to the thermal radiation source with a line segment AB, wherein the heated plane is parallel to the thermal radiation source, the line segment OA is perpendicular to the line segment AB, and the The heat radiation member is arranged between the heat radiation source and the heated plane, and the heat radiation of the heat radiation source passes through the radiation holes on the heat radiation member to heat the heated plane. Preferably, in order to facilitate analysis and calculation, The heat radiation member is perpendicular to the line segment OA at OA, that is, the radiati...

Embodiment 2

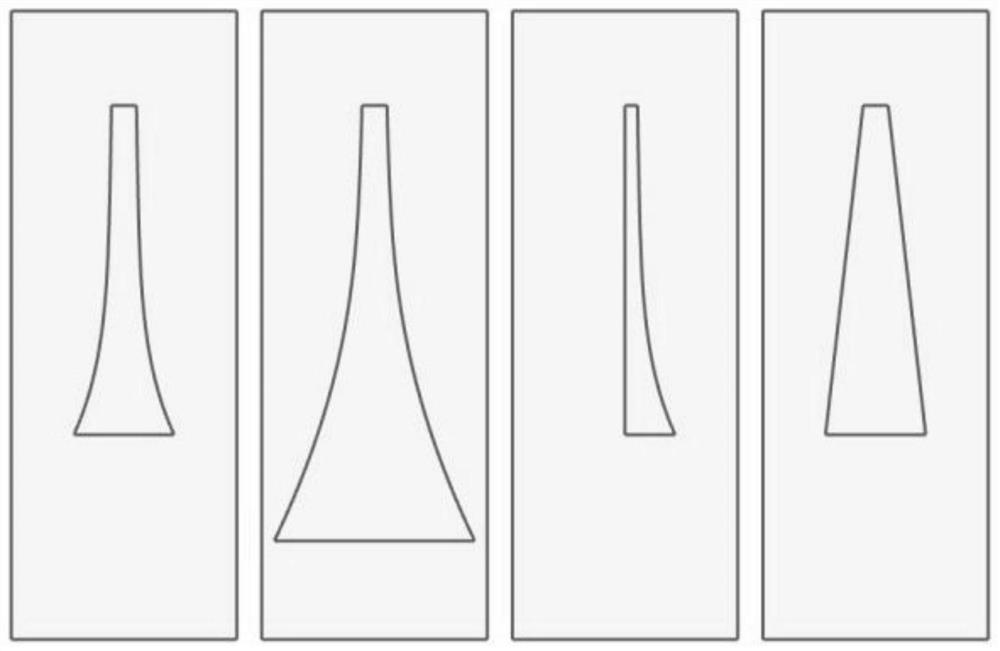

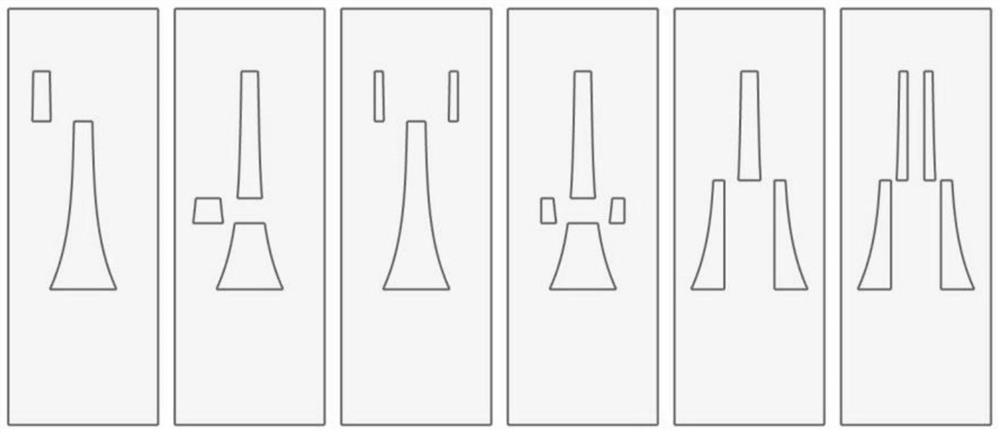

[0077] see Figure 4-7 As shown, this embodiment 2 discloses a structure of a heat radiation member, and the radiation hole of the heat radiation member is designed and manufactured using the radiation hole design method described in the above embodiment 1.

[0078] Specifically, it is assumed that the heat radiation source is marked with a point O, and the heating plane corresponding to the heat radiation source is marked with a line segment AB, and the line segment OA is perpendicular to the line segment AB, and the heat radiation member is arranged between the heat radiation source and the heating plane In between, the heat radiation rays of the heat radiation source pass through the radiation holes on the heat radiation member to heat the heated plane.

[0079] Preferably, in order to facilitate analysis and calculation, the heat radiation member is perpendicular to the line segment OA at OA, that is, the radiation line OA passes through the heat radiation member in a mann...

Embodiment 3

[0089] see Figure 8 with Figure 9 As shown, Embodiment 3 discloses a heat radiation assembly, and the heat radiation assembly includes the heat radiation member of Embodiment 2 and a heat radiation source 3, and the heat radiation source 3 is arranged inside or inside the heat radiation member .

[0090] In one embodiment, the heat radiation assembly includes side plates arranged on both sides of the heat radiation member, and the heat radiation source 3 is installed and fixed on the side plates.

[0091] Preferably, the heat radiation assembly is arranged on any one or several of the six walls of the oven, such as up, down, left, and right, and front and back, for uniform heating of the food in the oven,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com