Crushing auxiliary device for premixed mortar production

An auxiliary device and ready-mixed mortar technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult cleaning of raw materials and poor practicability, and achieve the effect of preventing sticking and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

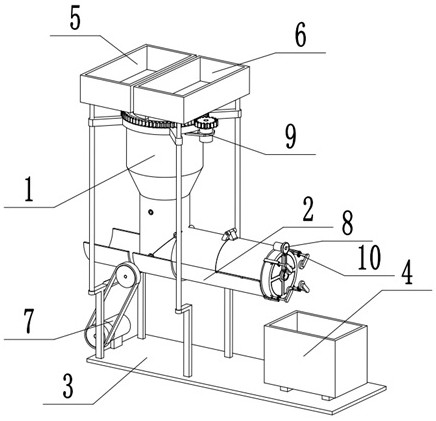

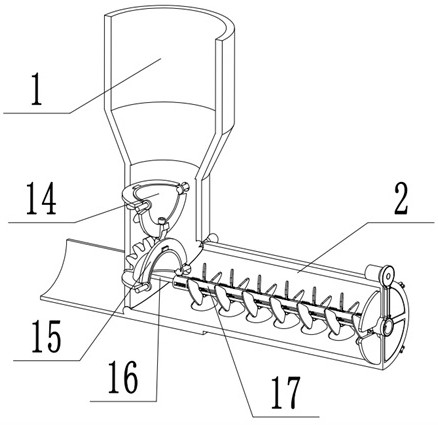

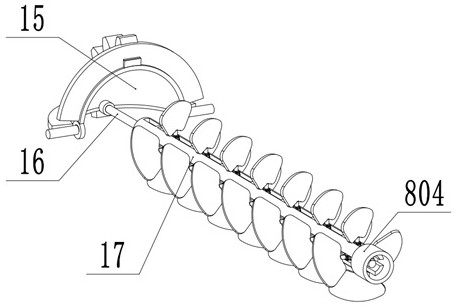

[0023] Example: such as Figure 1-Figure 4 The crushing auxiliary device for the production of ready-mixed mortar is shown, which includes a conveying bin 1 for feeding materials, a conveying crushing bin 2 for crushing mortar, a support frame 3, and a receiving chamber for crushed mortar. Tank 4, sand material storage tank 5 and slurry storage tank 6 for raw materials, conveying bin 1 and conveying crushing bin 2 are rotatably connected, conveying bin 1 is fixedly installed on frame 3, and conveying crushing bin 2 is rotatably installed on frame 3 Above, the material receiving tank 4 is fixedly installed on the frame 3, the sand material storage tank 5 is fixedly installed on the frame 3, the slurry storage tank 6 is fixedly installed on the frame 3, and the upper gear is installed on the conveying bin 1 to close Ring 14, the lower gear closed ring 15 is installed in rotation on the delivery bin 1, the upper gear closed ring 14 and the lower gear closed ring 15 form a gear fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com