Belt speed monitoring device of conveyor belt and application method of belt speed monitoring device

A monitoring device and conveyor belt technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as wear, conveyor belt slippage, and disordered steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

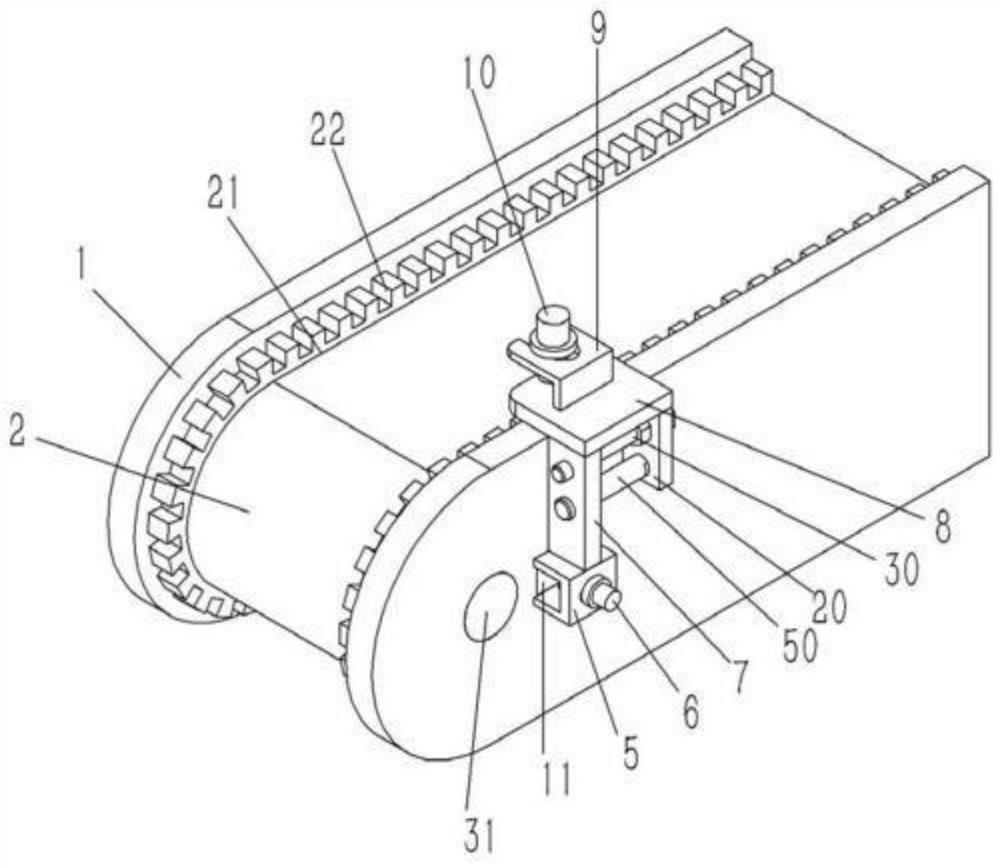

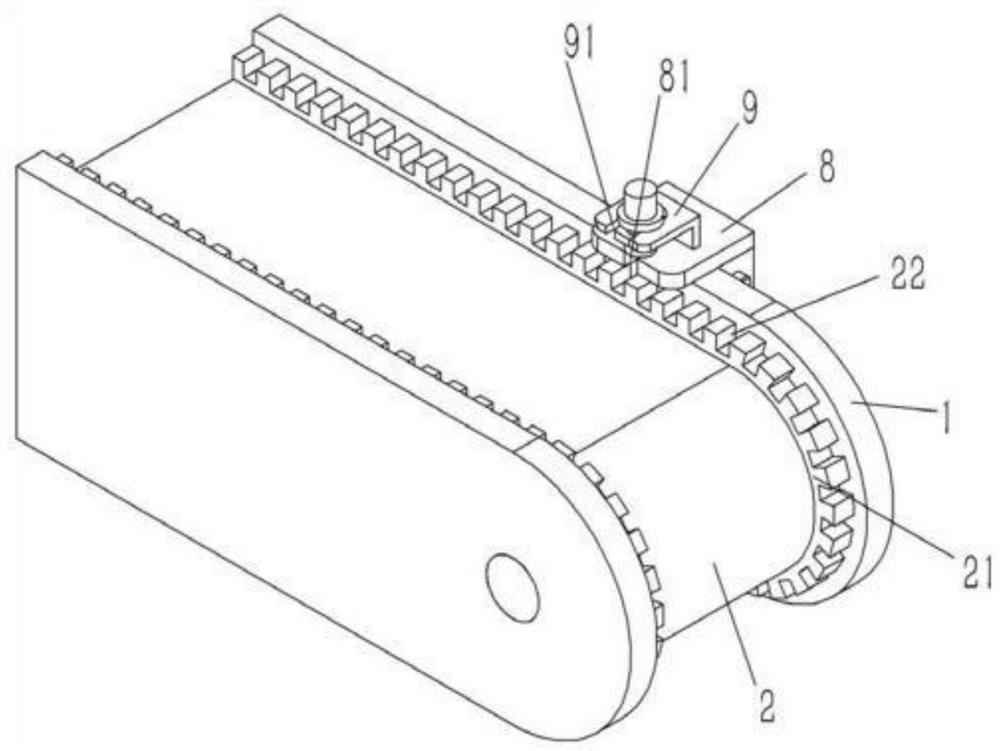

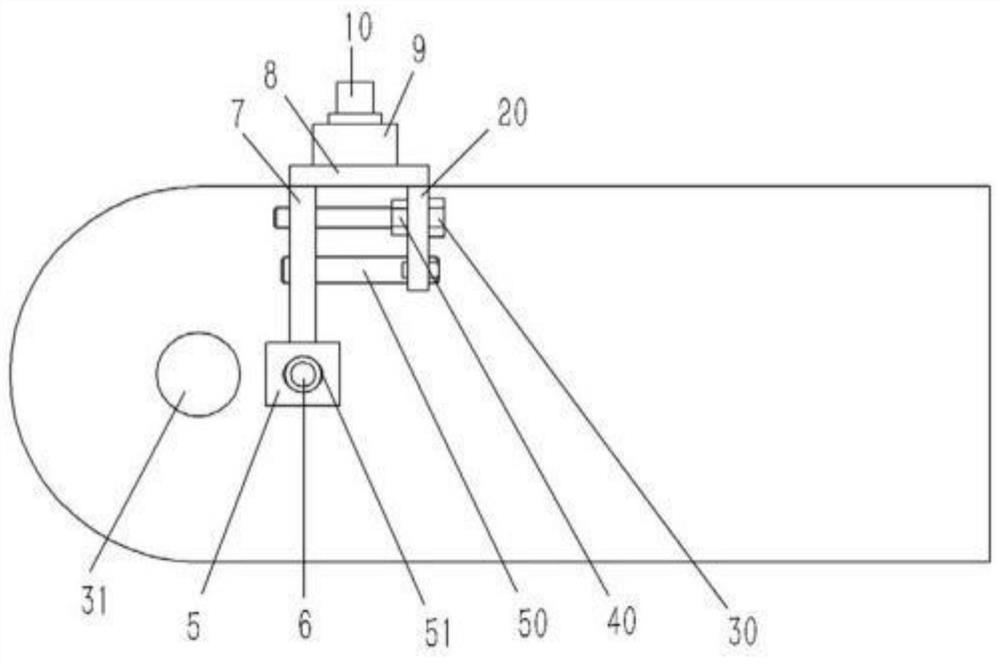

[0020] Example: see Figures 1 to 5 As shown, the belt speed monitoring device of the conveyor belt and its use method include the side support plate 1 of the conveyor belt and the belt body 2 of the conveyor belt. The roller and the rotating shaft of the servo motor are fixedly connected, and the two ends of the driving roller 3 are formed with hinged shafts 31, which are inserted into the side support plate 1; the friction roller sleeve 4 is fixed on the driving roller 3, and the belt body 2 Set and lean against the friction roller sleeve 4, the side end surface of the friction roller sleeve 4 is formed with a dimple 41, the side support plate 1 is formed with a window 11 opposite to the dimple 41, and the side support plate 1 is fixed There is a "匚"-shaped fixed bracket 5 opposite to the window 11, a first counting sensor 6 is fixed on the fixed bracket 5, and the probe of the first counting sensor 6 is opposite to the dimple 41 on the friction roller sleeve 4;

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com