Temperature strain monitoring system for fluid heating snow melting pavement

A monitoring system and temperature strain technology, applied in the application of thermometers, electrical/magnetic solid deformation measurement, thermometers, etc., can solve the problems of road surface safety, only focus on the effect of snow melting, etc., and achieve the effect of ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

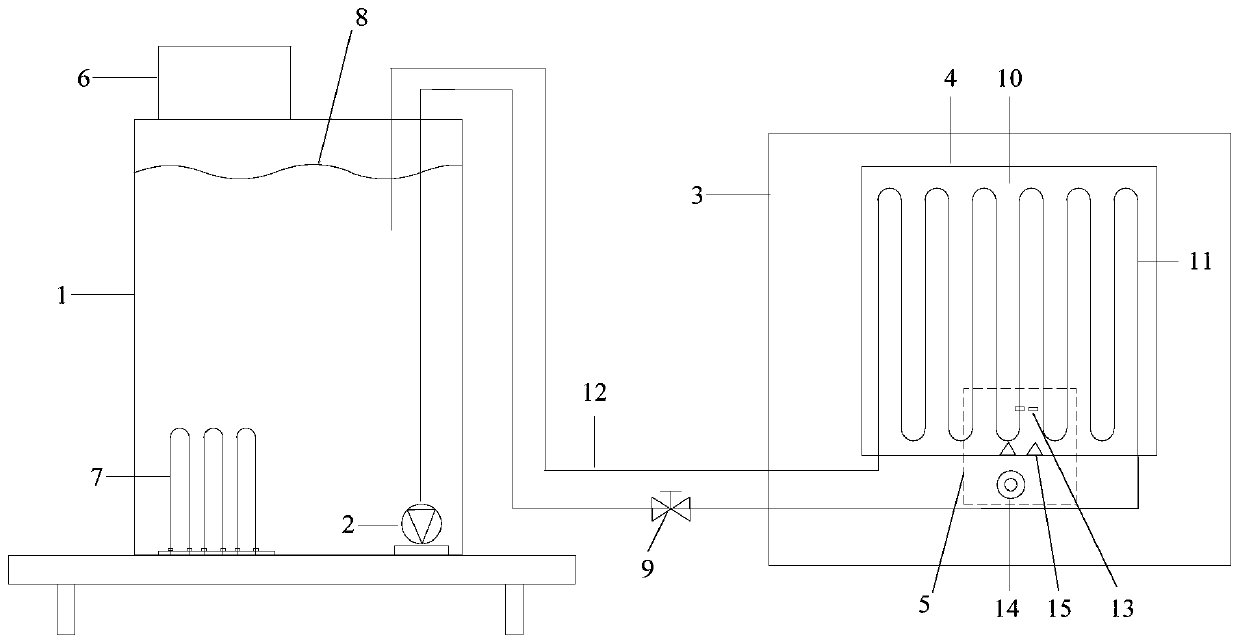

[0031] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment mode, a kind of fluid heating snow-melting road surface temperature strain monitoring system of this embodiment mode, it comprises heating system, circulating pump 2, environment box 3, road surface system 4, monitoring system 5, control valve 9 and two connection tube 12,

[0032] The heating system includes a heating water tank 1, a power distribution box 6 and an electric heating tube 7. The electric heating tube 7 is fixed on the inner bottom surface of the heating water tank 1, and the distribution box 6 is installed on the outer upper end surface of the heating water tank 1. The power distribution box 6 passes through the wire Connected with the electric heating tube 7, the distribution box 6 is used to control the opening and closing of the electric heating tube 7, and the power adjustment of the electric heating tube 7, and the upper side wall of the heating water tank 1 is ...

specific Embodiment approach 2

[0048] Specific implementation mode two: combination Figure 5 Describe this embodiment, the cement concrete pavement 10 internal pipeline 11 center line of the present embodiment is provided with a plurality of temperature sensors 13 along the vertical direction from top to bottom sequentially, the cement concrete pavement 10 internal adjacent pipeline 11 center line A plurality of temperature sensors 13 are arranged in sequence from top to bottom in the vertical direction, and the distance between all the temperature sensors 13 and the side surface of the cement concrete pavement 10 is 5 cm. So set, the temperature sensor 13 is used to monitor and record the temperature at different depths of the road surface. Other compositions and connections are the same as in the first embodiment.

[0049] The temperature sensor 13 of this embodiment is used to monitor and record the temperature at different depths of the road surface, the temperature measurement range is -50°C to +120°...

specific Embodiment approach 3

[0050] Specific implementation mode three: combination Image 6 Describe this embodiment. The digital speckle meter acquisition device in this embodiment includes a bracket, a slide rail, a lighting lamp, a camera A and a camera B. The bracket is erected on one side of the cement concrete pavement 10, and the slide rail is horizontally arranged on the bracket The lighting lamp is installed in the middle of the slide rail. Camera A and camera B are located on both sides of the lighting lamp. Both camera A and camera B are slidingly connected with the slide rail. The lens of camera A and the lens of camera B Both the lens and the lighting lamp are directed towards the end surface to be measured of the cement concrete pavement 10 , and the signal output terminals of the camera A and the camera B are connected with the signal input terminal of the digital speckle meter 14 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0051] The digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com