Modular fabricated high-pile wharf structure and construction method thereof

A technology of high-pile wharf and construction method, applied in the field of wharf structure, to achieve the effects of reducing workload, improving construction efficiency, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

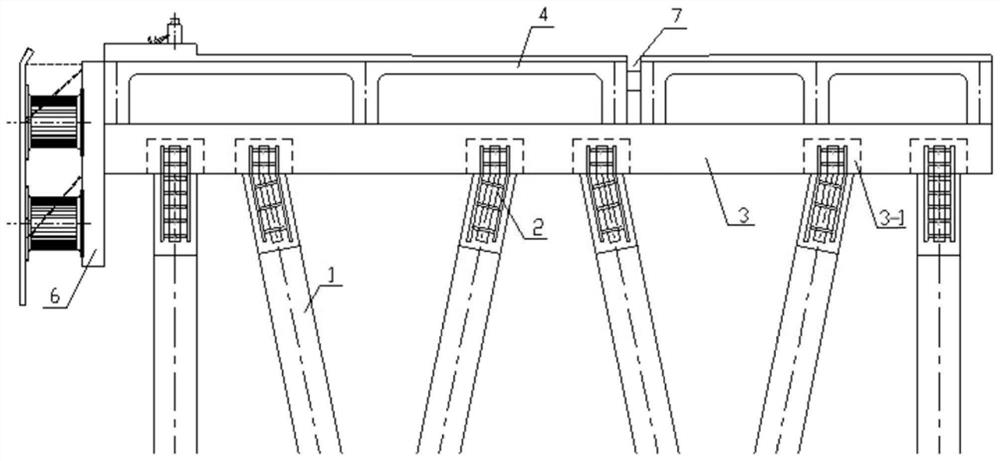

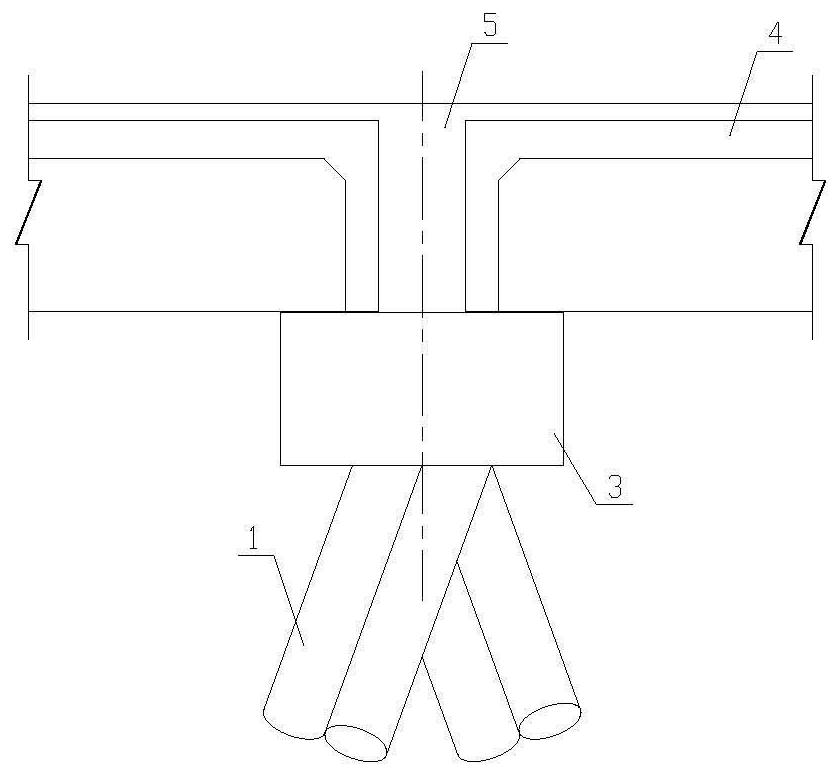

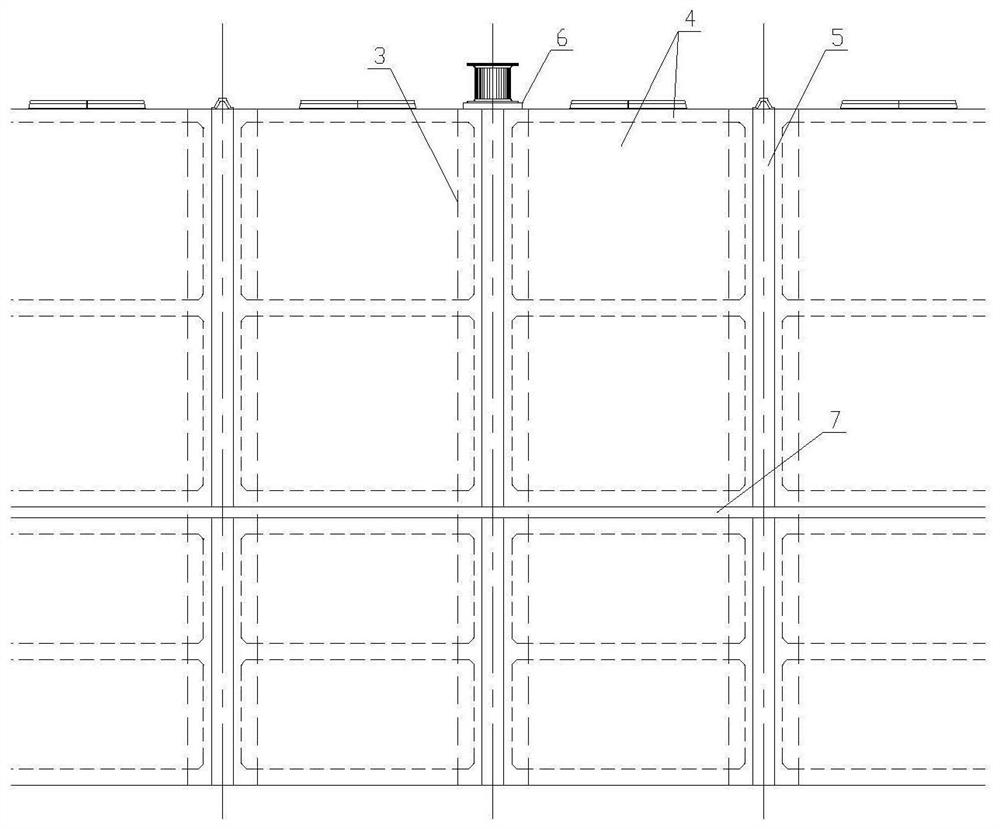

[0040] For the high-piled wharf, this scheme abandons the existing "prefabricated + cast-in-place" traditional structural combination, and innovatively adopts a prefabricated modular assembly structure for the upper components of the high-piled wharf to realize the prefabricated modular assembly of the high-piled wharf , Breaking the pattern of multi-component prefabrication, multi-node connection, and multi-cast-in-place design of the conventional wharf.

[0041] In this scheme, the upper components of the high-piled wharf with prefabricated modular assembly structure mainly include modular pile foundations, modular steel structure pile cores, modular beams, modular π-plates, and modular fender systems.

[0042] The modular pile foundation here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com