Fabricated steel joint

A kind of steel joint and assembly technology, which is applied in the direction of construction and building structure, can solve the problems of high construction difficulty and complicated welding process, and achieve the effect of improving assembly speed and quality, improving joint bearing capacity and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

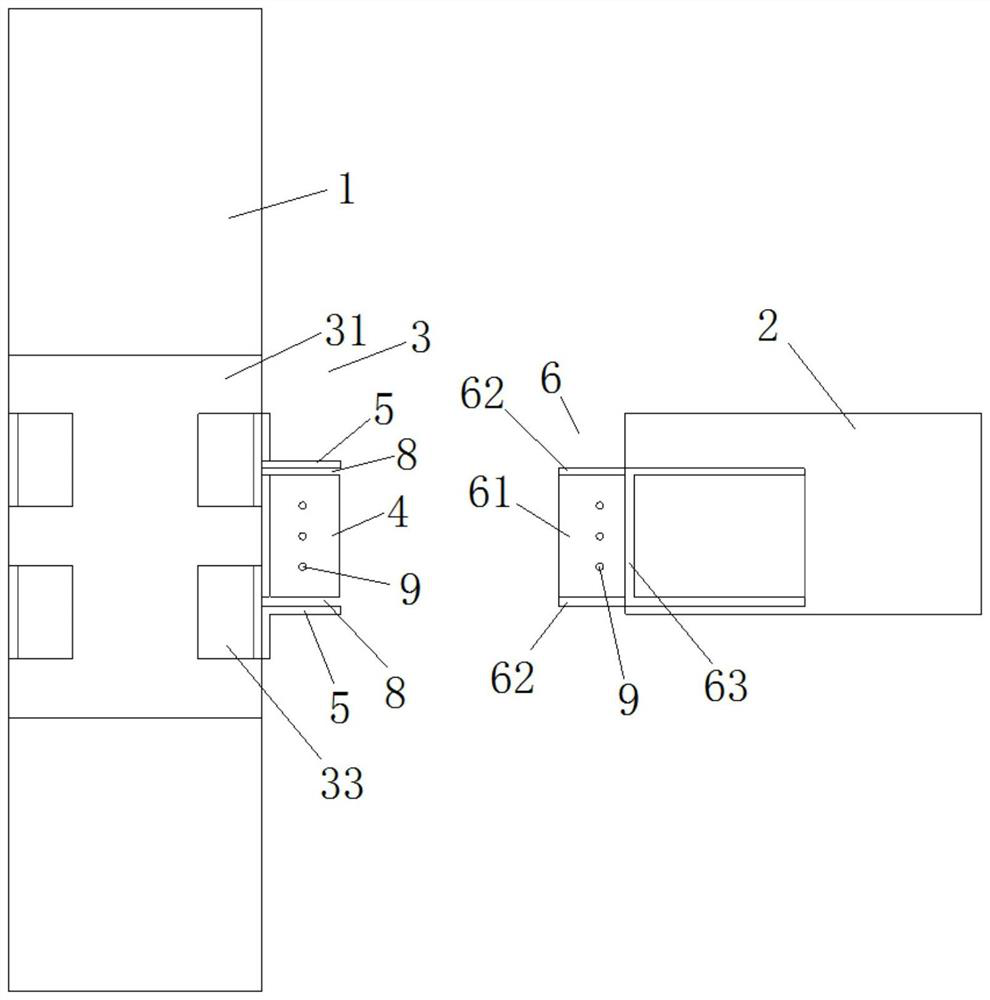

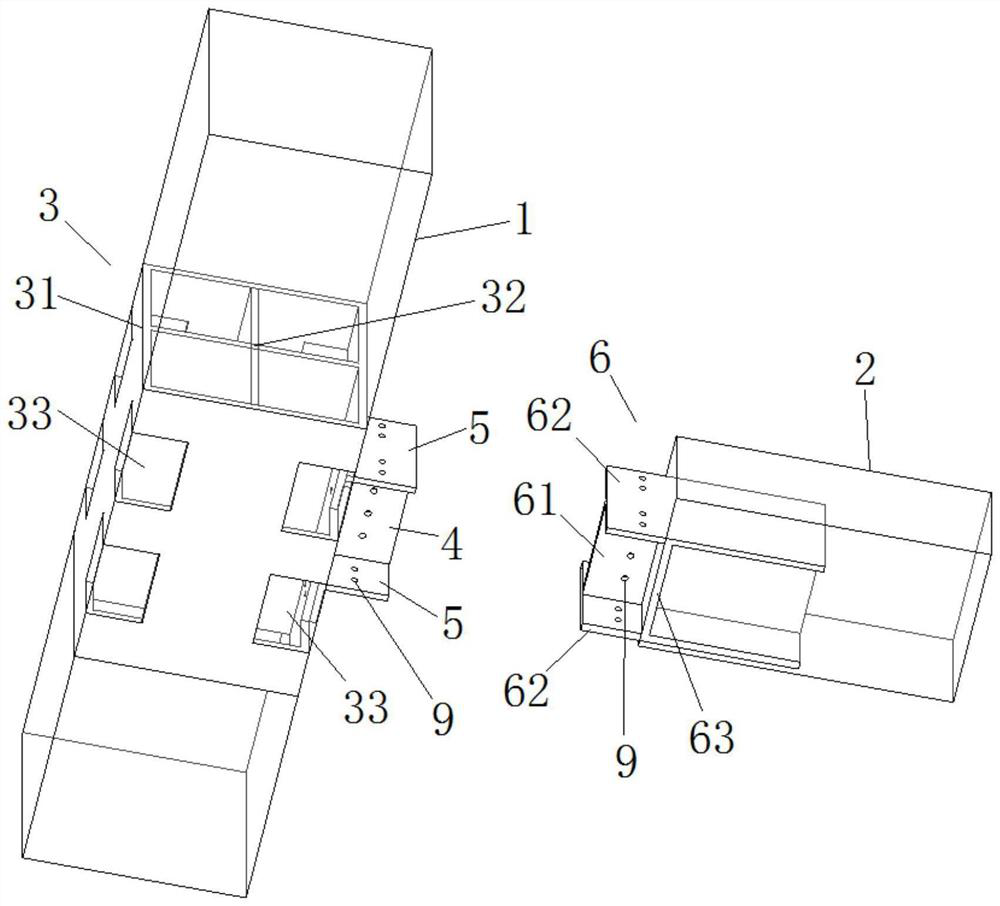

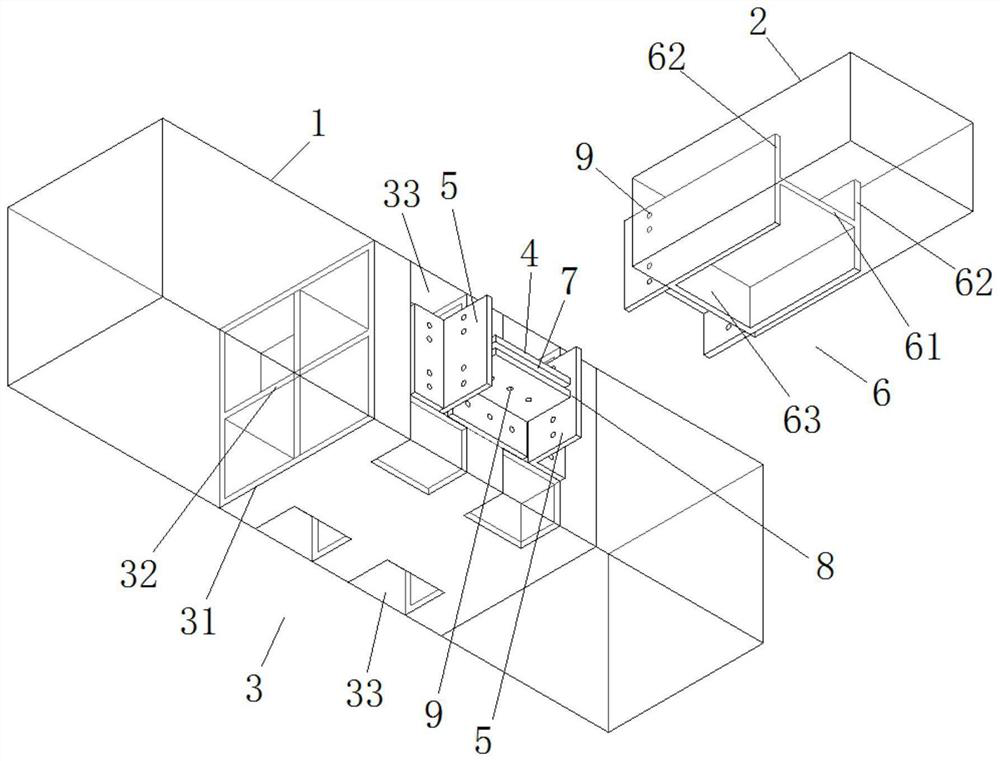

[0038] like Figure 1 to Figure 5 As shown, an assembled steel node provided in this embodiment is used to connect reinforced concrete column 1 and reinforced concrete beam 2, including: steel frame 3, web connector 4, corbel connector 5 and I-shaped steel 6. Among them, the steel frame 3 is poured in the reinforced concrete column 1, and the steel frame 3, concrete, and steel bars form a whole, which greatly improves the overall installation stability and strength; the web connector 4 and the corbel connector 5 are fixed on the steel frame 3 toward On one side of the reinforced concrete beam 2, one end of the I-shaped steel 6 is poured in the reinforced concrete beam 2, and the other end is fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com