Polygonal concrete frame column formwork supporting construction method

A formwork support and construction method technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem that the support rod cannot be stably fixed and effectively fixed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

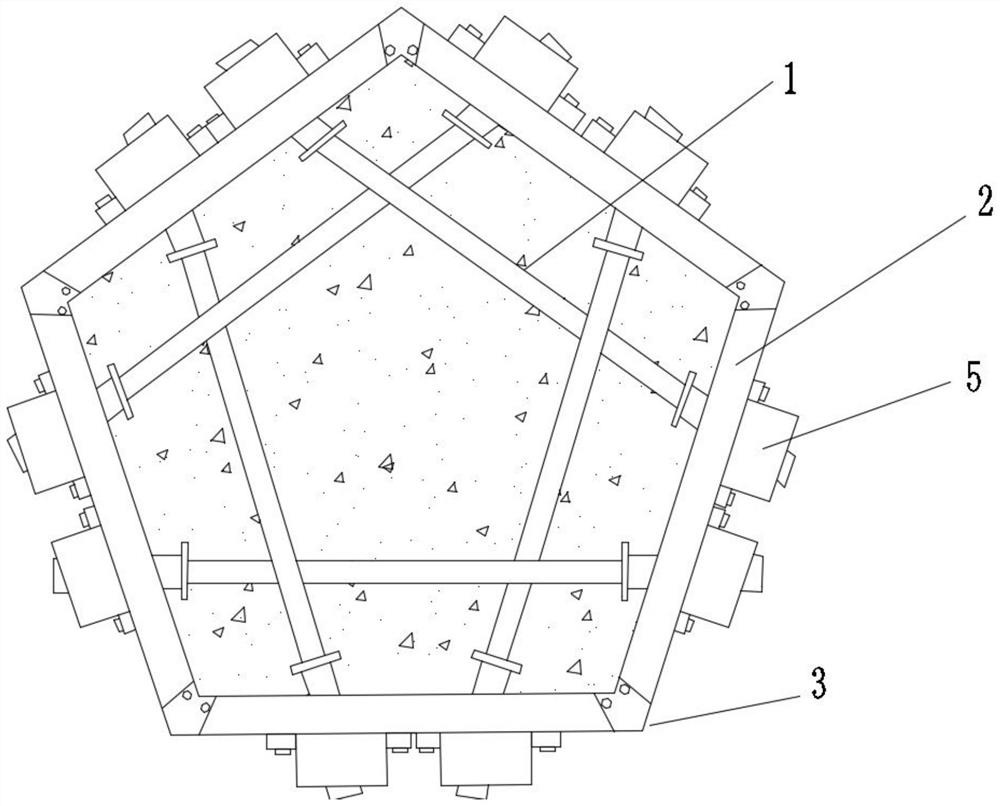

[0046] like Figure 1 to Figure 8 Shown, is an embodiment of the present invention, a construction method for polygonal concrete frame column formwork support, comprising the following steps:

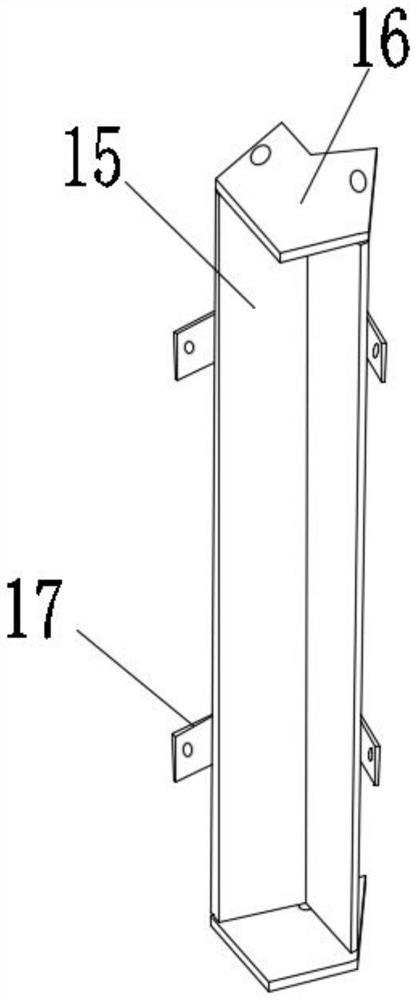

[0047] Step 1. Design drawings. Calculate the reasonable number and length of support rods 1 according to the polygonal concrete columns that need to be cast and formed, and calculate the size and required number of the required column formwork 2. The size of multiple groups of column formwork 2 same;

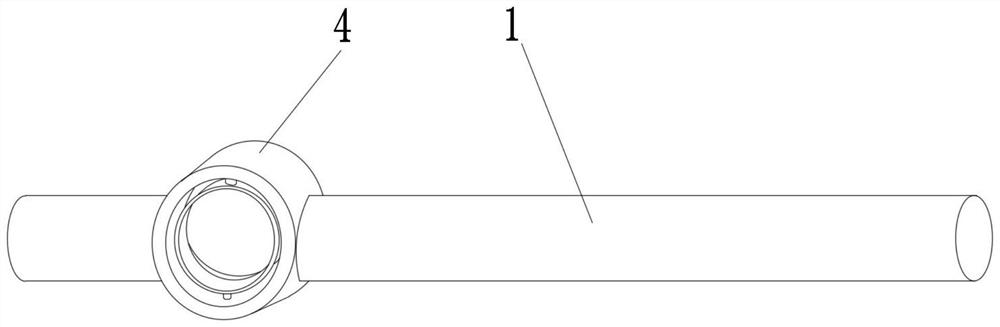

[0048]Step 2: According to the design requirements, a positioning hole is defined on the column formwork 2, and the positioning hole is 1 / 3 of the column formwork 2 along the plate surface, and a support rod 1 is connected between every three groups of continuous column formwork 2 and the support rod 1 is parallel to the The middle column template 2;

[0049] Step 3: Combine the corresponding column formwork 2 for the first time, so that multiple groups of column formwork 2 are arrange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap