Novel double-valve type continuous circulating valve with clamping device

A technology of clamping device and circulation valve, which is applied in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve problems such as dangerous accidents, and achieve the effect of improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

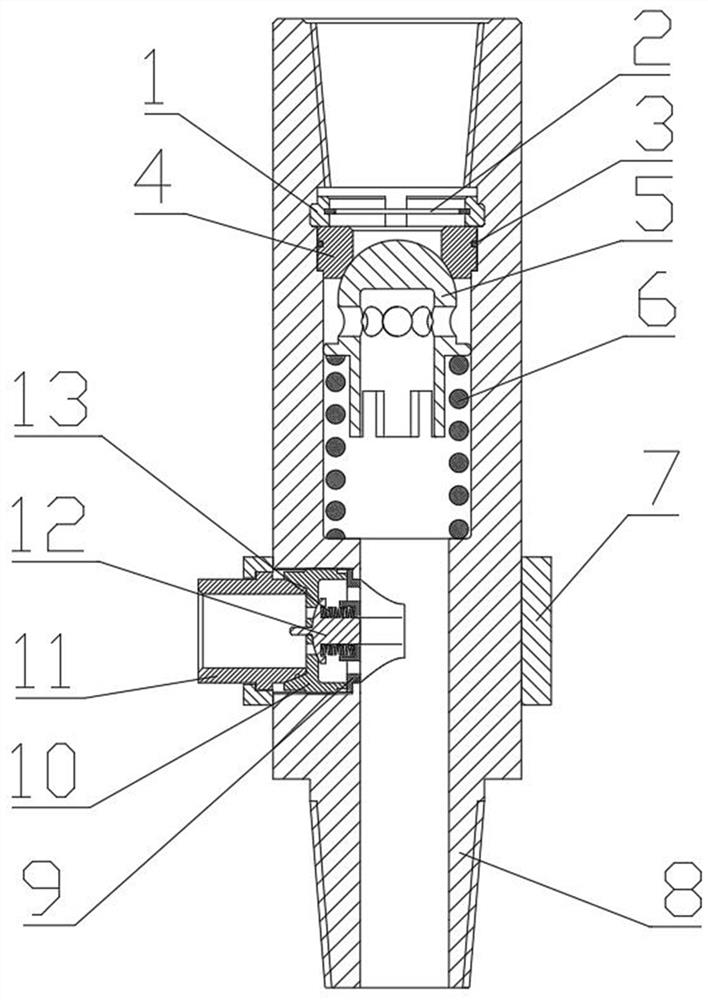

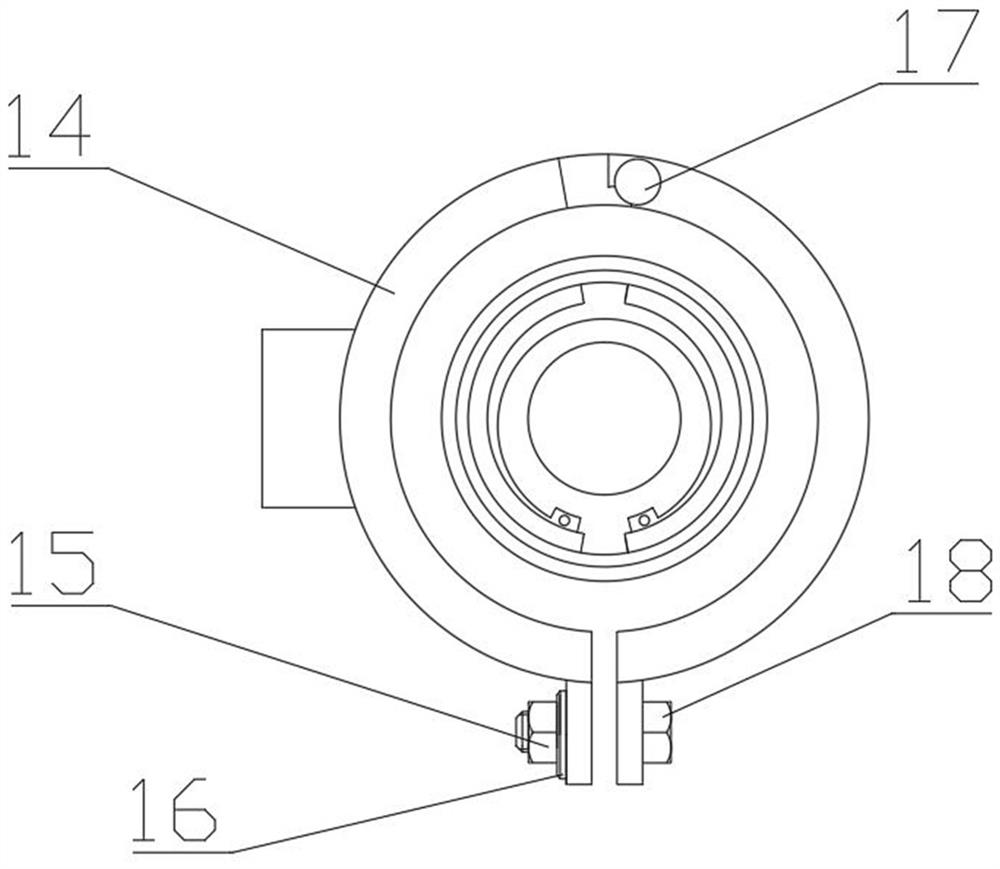

[0044] like Figure 1-Figure 2 Shown:

[0045] This embodiment provides a new double-valve type continuous circulation valve with its own clamping device, including a main through valve 5, a shorting body 8, an intermediate joint 11 and a bypass valve 12, wherein:

[0046] The short-connecting main body 8 is a hollow short shaft structure, and both ends of the short-connecting main body 8 are provided with threaded sections;

[0047] The main valve 5 and the main valve spring 6 are arranged in the short-circuit main body 8;

[0048] The lower end of the main valve 5 is provided with a main valve spring 6, and the upper end is provided with a main valve seat 4;

[0049] The main through valve seat 4, main through valve 5 and main through valve spring 6 are press-fitted inside the shorting main body 8 through the main through valve limiting device 1;

[0050] The lower side of the shorting body 8 is provided with a step hole, the step hole is located below the main valve spri...

Embodiment 2

[0063] This embodiment provides a new double-valve type continuous circulation valve with its own clamping device, including a main through valve 5, a shorting body 8, an intermediate joint 11 and a bypass valve 12, wherein:

[0064] The short-connecting main body 8 is a hollow short shaft structure, and both ends of the short-connecting main body 8 are provided with threaded sections;

[0065] The main valve 5 and the main valve spring 6 are arranged in the short-circuit main body 8;

[0066] The lower end of the main valve 5 is provided with a main valve spring 6, and the upper end is provided with a main valve seat 4;

[0067] The main through valve seat 4, main through valve 5 and main through valve spring 6 are press-fitted inside the shorting main body 8 through the main through valve limiting device 1;

[0068] The lower side of the shorting body 8 is provided with a step hole, the step hole is located below the main valve spring 6, and a bypass valve seat 10 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com