Low-power-consumption jet type refrigerating system equipped with thermal driving pump

A refrigeration system and heat-driven technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high power consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

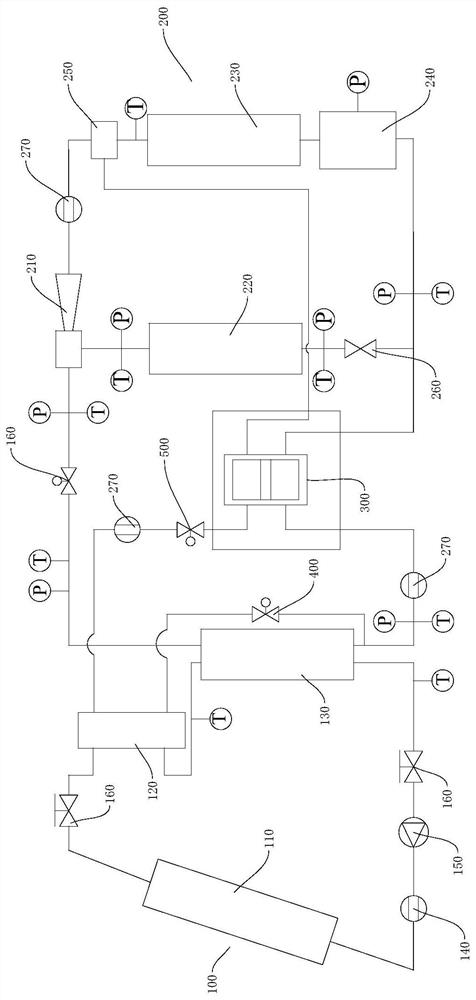

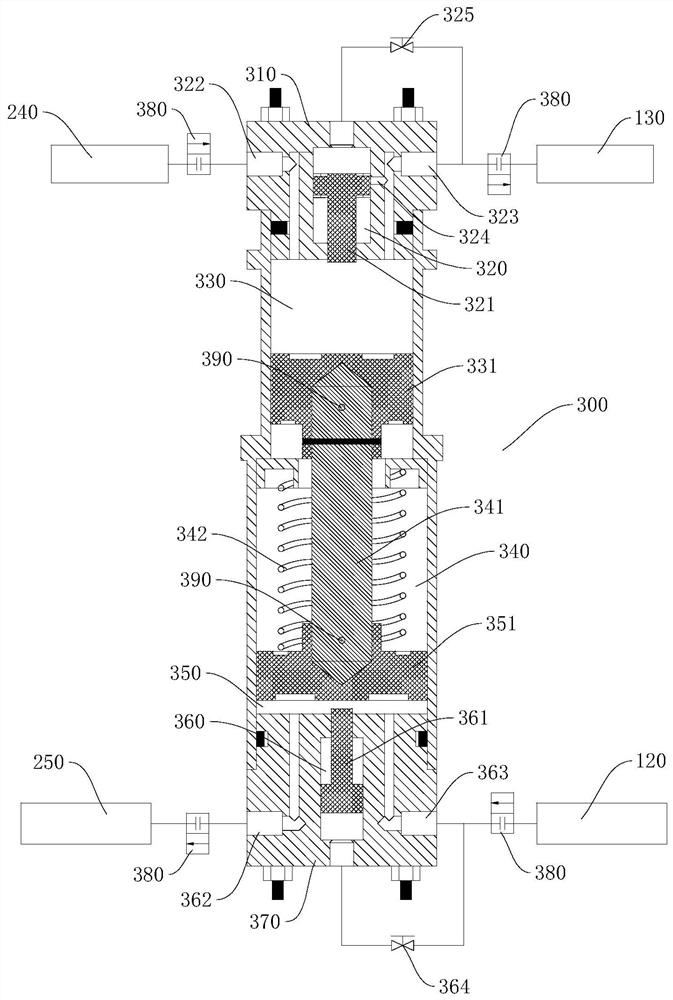

[0026] like figure 1 , figure 2 As shown, the present invention is a low-power ejection refrigeration system equipped with a heat-driven pump, comprising: an ejector refrigeration cycle 200, which includes a high-pressure vessel 120, a generator 130, an ejector 210, an evaporator 220, a condenser 230, The accumulator 240, the mixing chamber 250, the heat-driven pump 300, the electronic expansion valve 260, the mass flow meter 270, and the high-pressure vessel 120 are used to generate high-pressure gas; the heat collection cycle 100 includes the heat collector 110, the heat collector 110 and the The high-pressure container 120 is connected to the generator 130, and the heat collection cycle 100 uses water as a heat carrier, and the heat carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com