Manufacturing process for bearing rings

A manufacturing process and technology of bearing rings, applied in the direction of bearing components, shafts and bearings, engine components, etc., can solve the problems of poor anti-brittle performance of the structure, easy shaking, and reduced communication prohibition period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

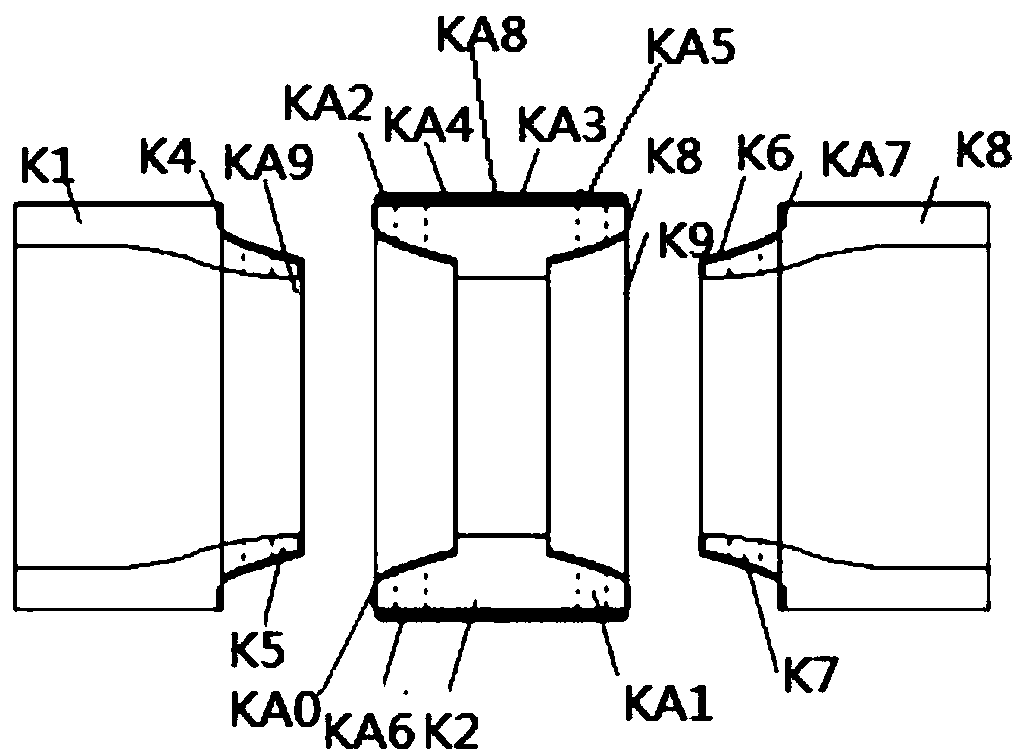

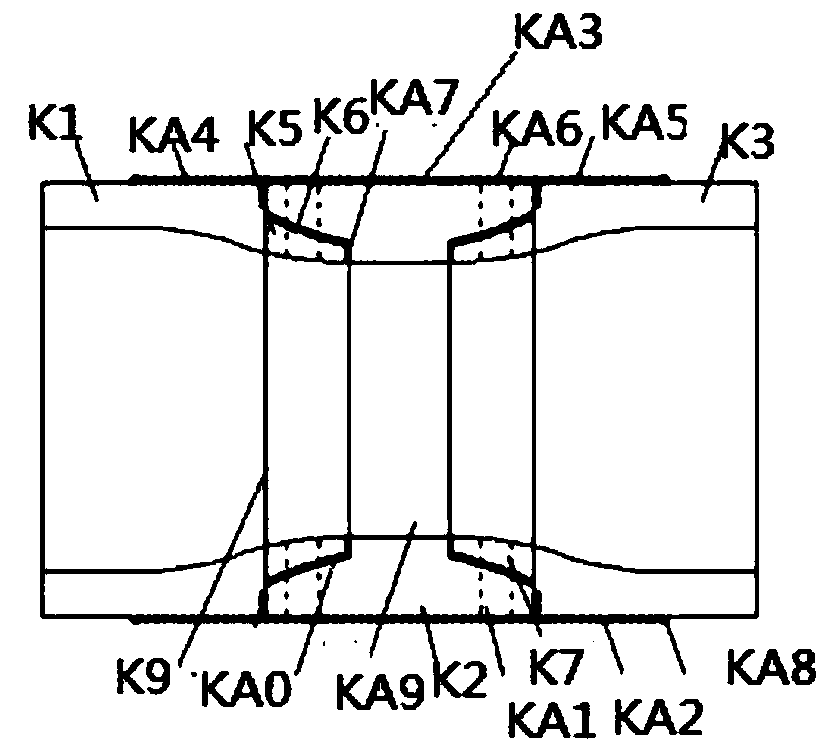

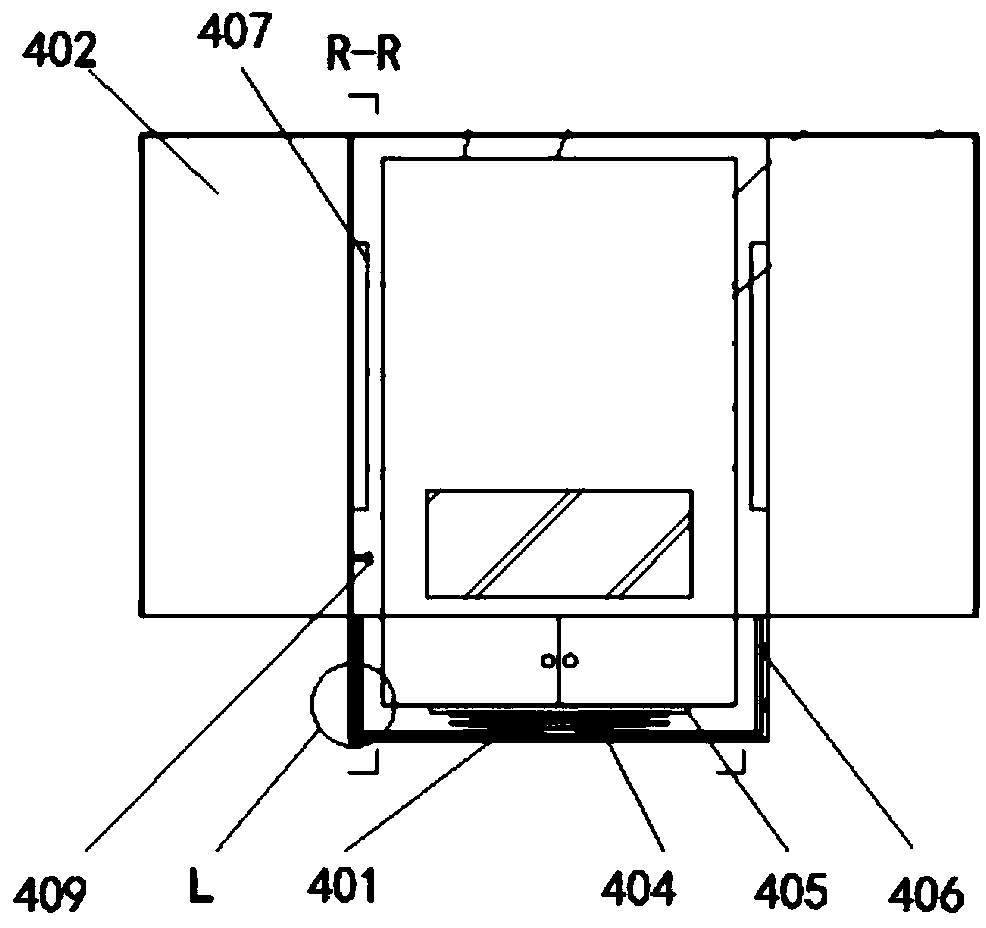

[0085] Such as Figure 1-Figure 5 As shown, for the manufacturing process of the bearing ring, including the bearing ring manufacturing method described in the application number "201680051928.X", the application date is "2016.08.23" and the patent name is "bearing ring manufacturing method";

[0086] The bearing ring manufacturing method, the method comprising: a first step of setting a steel material heated to a temperature not lower than the A1 transformation point on a forming table and punching out a ring member from the steel material and thereafter forming and quenching the ring on the forming table The second step of the component;

[0087] The forming table includes a first mold and a second mold; the second mold is configured to be divided into an inner cylinder and an outer cylinder; in the second step, by placing a steel material between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com