Liquid lens and electronic equipment

A liquid lens and lens barrel technology, which is applied in the field of photography, can solve problems such as unsatisfactory zoom effects, achieve ideal zoom effects, and increase the effect of zoom range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

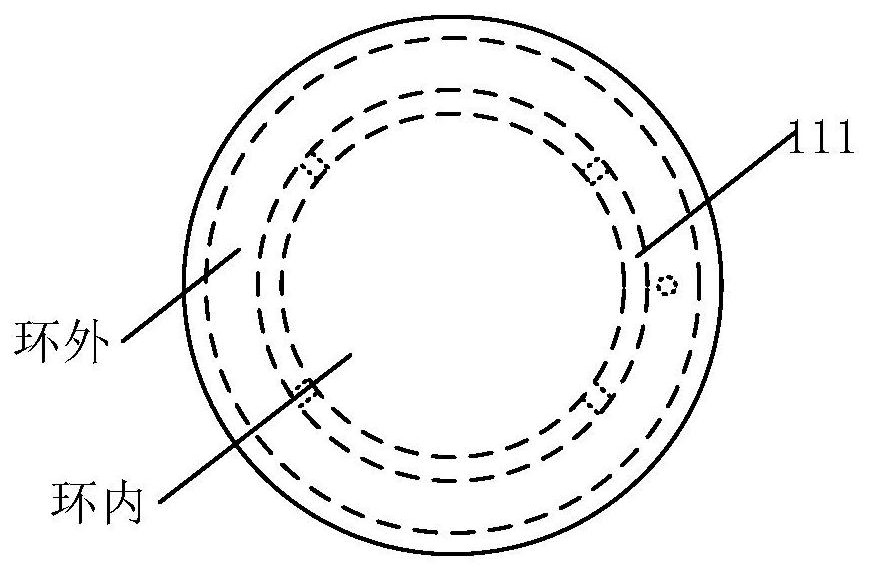

[0046] Assuming that the moving part 13 is a magnetically permeable structure, then, as Figure 5 As shown, the pressure adjustment assembly can also include a first magnetic part 14, the first magnetic part 14 is arranged in the inner cavity 110, and is arranged opposite to the moving part 13; wherein, the first magnetic part 14 is configured to apply Magnetic force to drive the moving part 13 to move.

[0047] In Example 1, the structure of the first magnetic part 14 may correspond to that of the moving part 13 , for example, when the moving part 13 has a ring structure, the first magnetic part 14 may also have a ring structure, which is not limited here.

[0048] Based on this, assuming that the first medium is gas and the second medium is liquid, then the following combination Figure 6a-Figure 6c The focusing process of the liquid lens in Example 1 will be described.

[0049] (1) In the natural state, no current is applied to the first magnetic member 14 (also can be un...

example 2

[0054] Assuming that the moving part 13 is a magnetically permeable structure, then, as Figure 7 As shown, the pressure adjustment assembly can also include a second magnetic part 15, which can be arranged outside the lens barrel 11 and opposite to the moving part 13; wherein, the second magnetic part 15 is configured to move toward the moving part 13 applies a magnetic force to drive the moving part 13 to move.

[0055] In this example 2, the mutual attraction between the electromagnet (that is, the moving part 13) and the ferrofluid (that is, the second magnetic attraction part 15) is utilized, and the moving part is controlled by controlling the second magnetic attraction part 15 (active ring) 13 (driven ring) moves up and down, when the moving part 13 moves up and down, the extrusion of the first medium or the second medium can make the flexible film 12 complete the switching of concave lens-plane mirror-convex lens, increasing the zoom range.

[0056] Wherein, the focus...

example 3

[0060] Please refer to Figure 8 , the pressure regulating assembly may further include a piezoelectric driving device 16 disposed in the inner cavity 110 to drive the moving member 13 to move through deformation.

[0061] In this example 3, the piezoelectric driving device 16 can be a piezoelectric element made of piezoelectric material, that is to say, in this example 3, the deformation characteristics of the piezoelectric material are used to realize the moving part 13 (that is, the driven Ring) up and down to achieve zoom effect.

[0062] It can be understood that general piezoelectric materials are divided into three categories according to the crystallization method. The first type is single crystal structure such as quartz; the second type is polycrystalline structure ceramics, such as barium titanate piezoelectric ceramics (BaTiO3), lead zirconate titanate series Piezoelectric ceramics (PZT); the third type of polymer piezoelectric materials such as polyvinylidene flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com