Fraction mass weighted average particle size calculation method

A quality weighted average and calculation method technology, applied in complex mathematical operations, grain processing, etc., can solve problems such as large deviations of production parameters, control material sources, evaluate process crushing efficiency, etc., achieve reliable evaluation and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

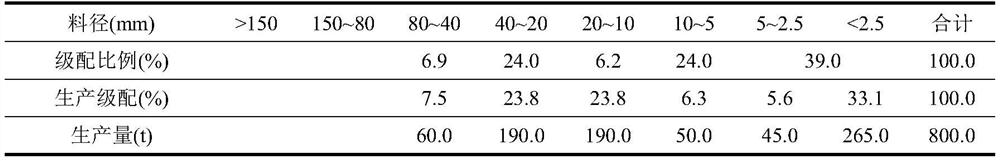

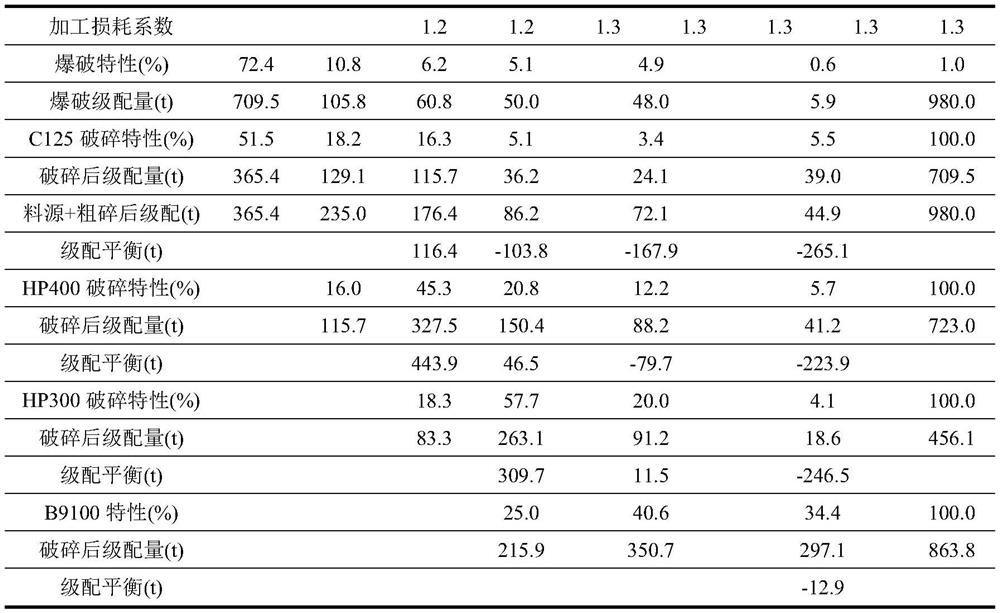

[0031] A method for calculating the weighted average particle diameter of particle size mass according to the present invention comprises the following main steps:

[0032] A. Calculation of A in the single-grain fraction n =(a max +a min ) / 2, where a max is the maximum mineral particle size in the single-grain class, a min is the smallest mineral particle size in the single-grain grade;

[0033] B. Calculation of single-grain quality weight C n = M n / Q, where M n is the mass of single-grained ore, and Q is the total mass of ore;

[0034] C. Calculate the weighted average particle size K=(A 1 ×C 1 )+(A 2 ×C 2 )+…+(A n ×C n );

[0035] D. According to step A to step C, respectively calculate the weighted average particle size K of the feed particle size 进 And the mass-weighted average particle size K of the output p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com