Large-scale shielding motor flywheel shell hot jacket process

A technology for shielding motors and shrink-fitting technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of difficulty in maintaining workpiece level, assembly gap and shrink-fit time, uneven heating temperature, and roundness of thin-walled parts. Poor and other problems, to achieve the effect of easy deflection, simple thermal installation, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

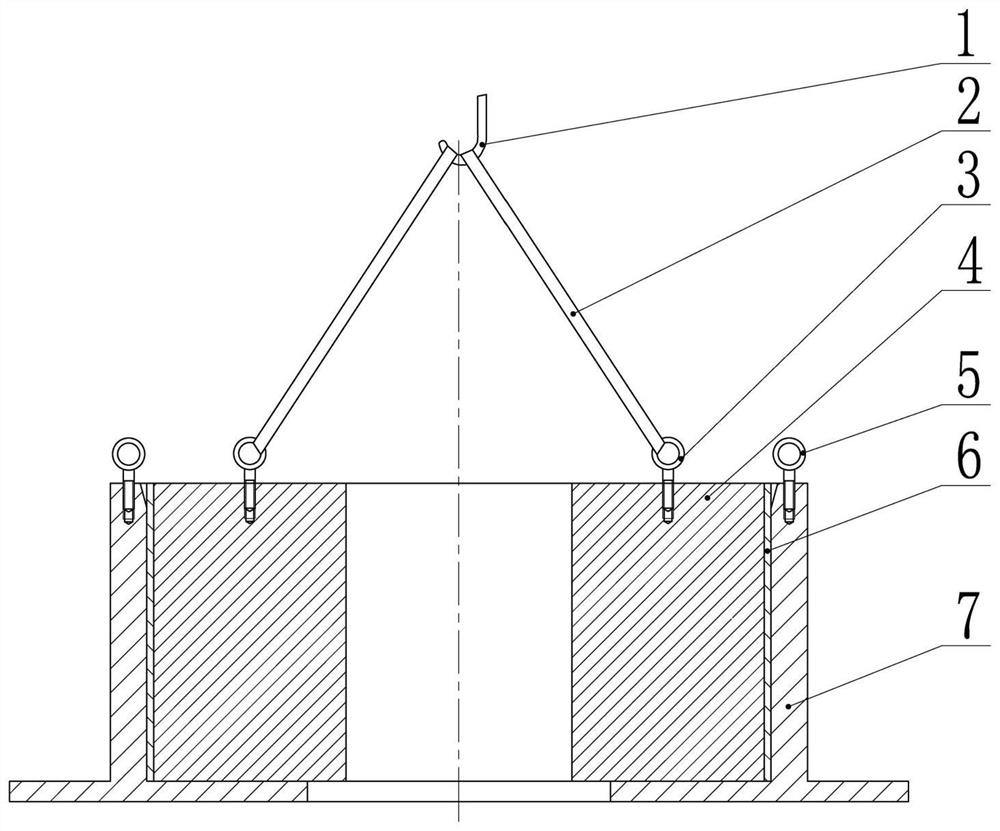

[0017] Such as image 3 As shown, a large-scale shielded motor flywheel shell shrink-fit process is assembled using a crane 1, a sling 2, a first suspension ring 3, a second suspension ring 5, and an insulation cylinder 7. The method includes the following steps:

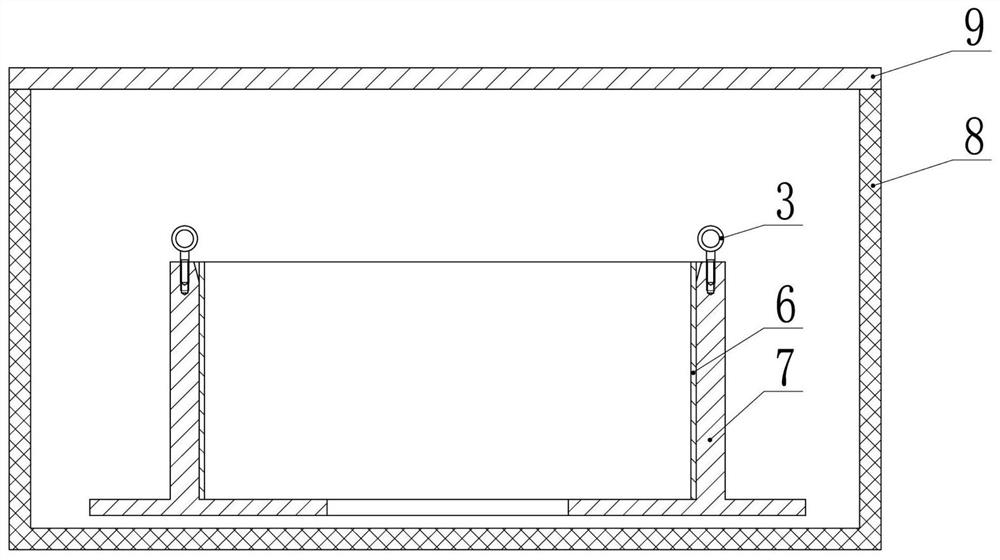

[0018] a) if figure 1 As shown, install the flywheel casing 6 into the heat preservation tube 7, adjust the flywheel casing to a circle, so that the roundness tolerance of the inner hole of the flywheel casing 6 is less than 0.1mm;

[0019] b) if figure 1 As shown, the insulation cylinder 7 equipped with the flywheel shell 6 is put into the heating furnace 8 as a whole for heating by using the second suspension ring 5;

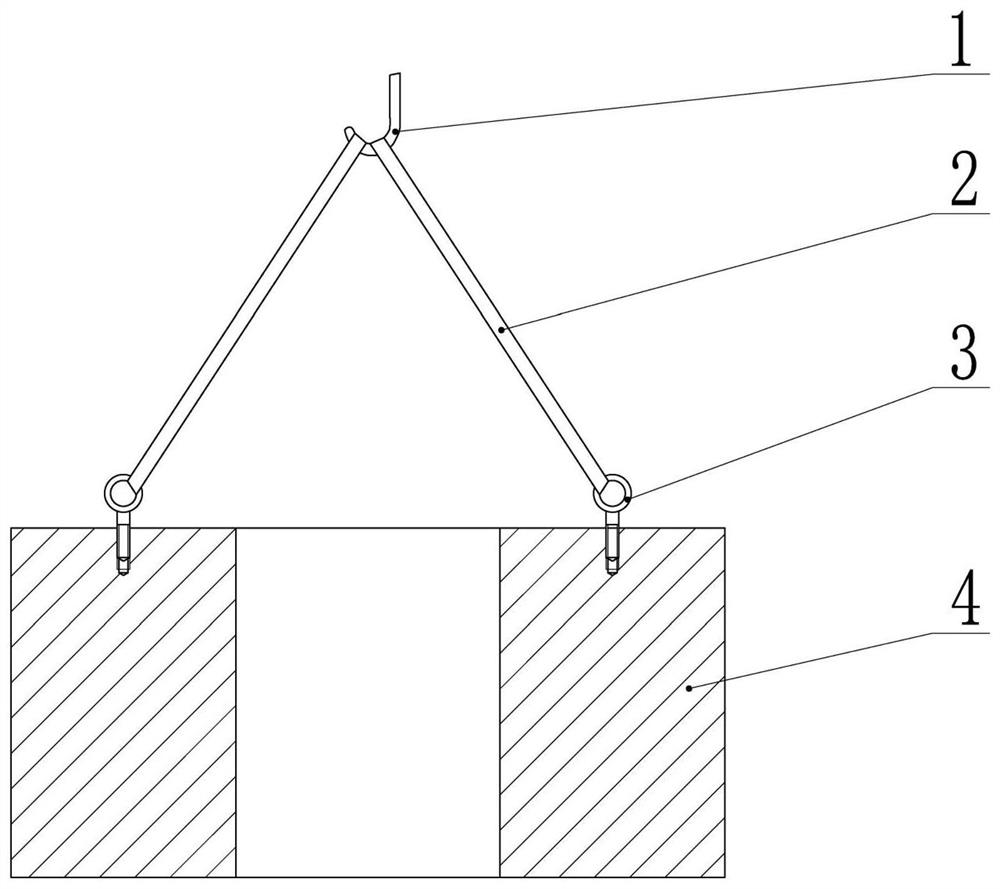

[0020] c) if figure 2 As shown, use the crane 1, the sling 2 and the first lifting ring 3 to lift the flywheel 4, and adjust the levelness of the upper end surface of the flywheel 4 to within 0.2mm through the sling 2;

[0021] d) if image 3 As shown, after the heat preservation cylinder 7 eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com