High-pressure cleaning machine for microscope lens

A technology for high-pressure cleaners and microscope lenses, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. The effect of liberating manpower, reasonable structure and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

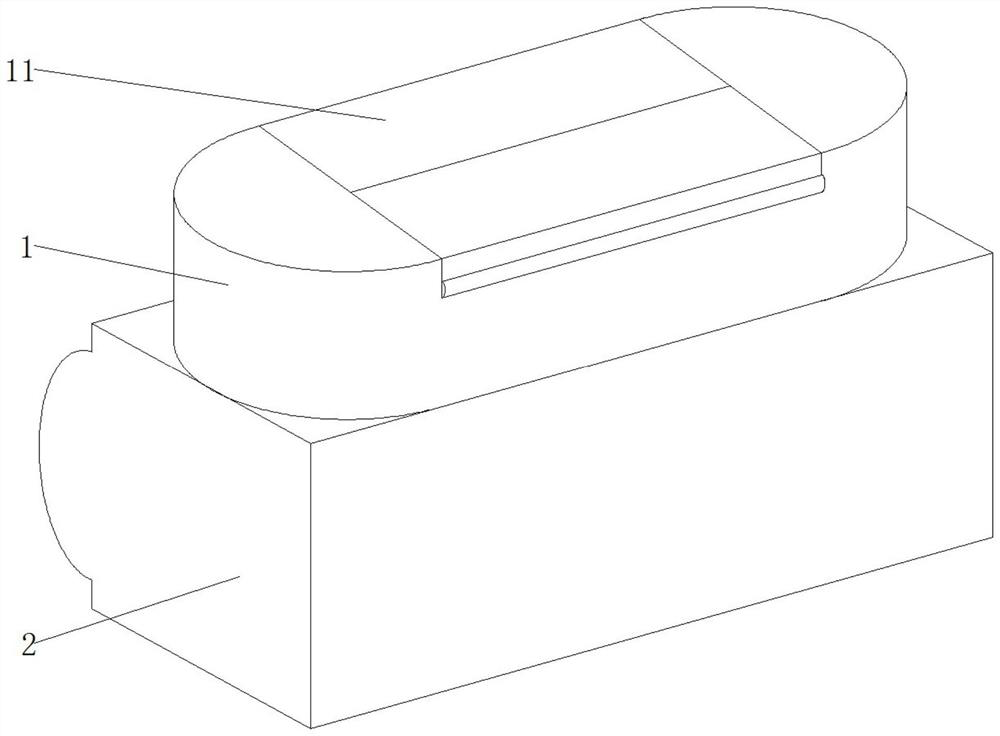

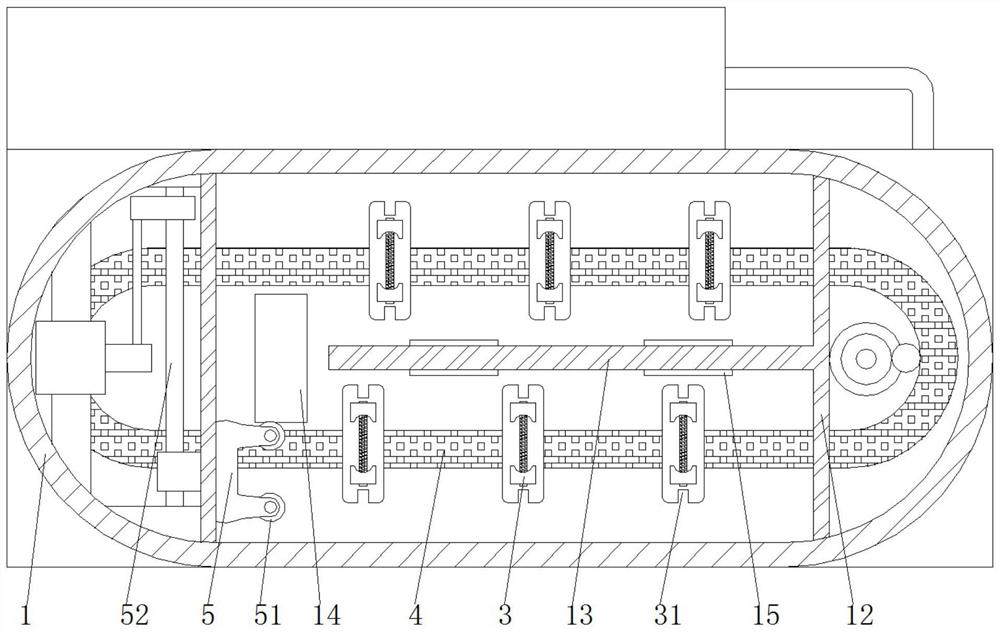

[0029] Specific implementation mode one: please refer to Figure 1-6 , the present invention provides a technical solution: a high-pressure cleaning machine for microscope slides, comprising:

[0030] The upper layer 1 and the lower layer 2 are stacked up and down and connected together, and the upper layer 1 is connected to the lower layer 2 through the communication groove 14; the front sides of the upper layer 1 and the lower layer 2 can be made of transparent material, which is convenient for observing the lens cleaning progress.

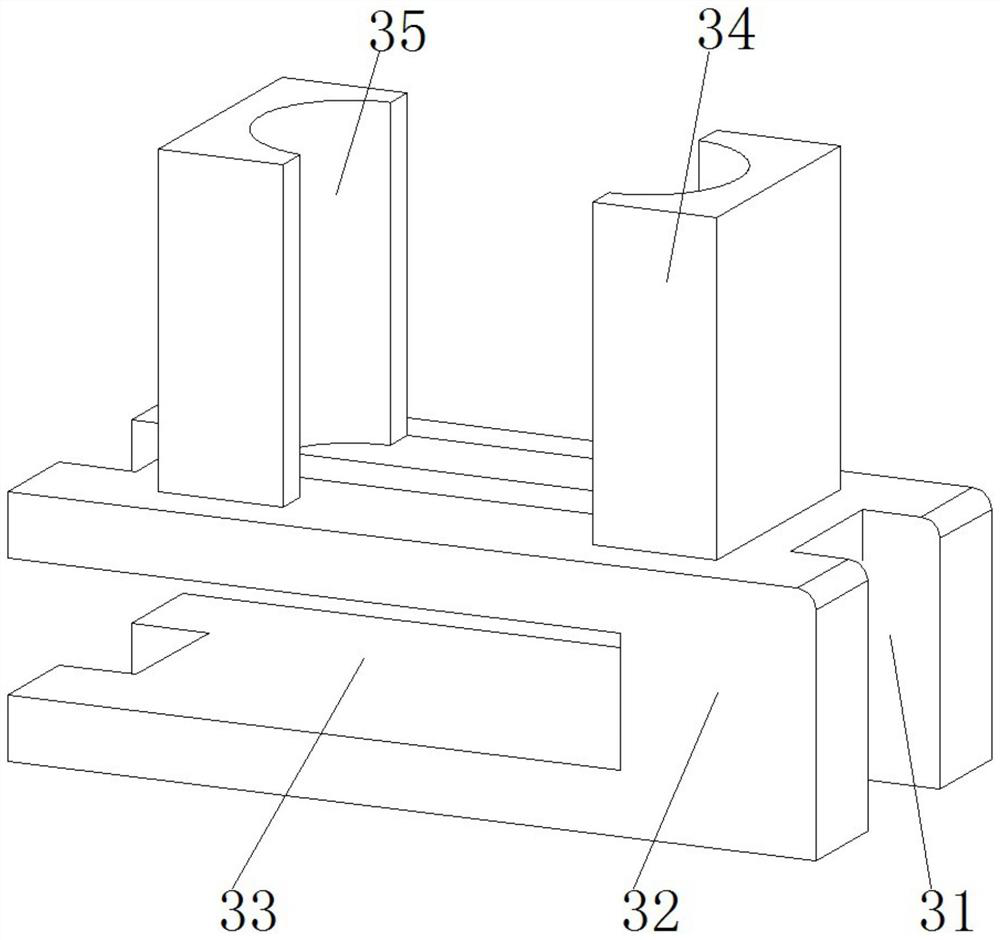

[0031] The clamping mechanism 3 is clamped on the transmission belt 4. The clamping mechanism 3 includes a base 32 and a clamping block 34 installed on the top surface of the base 32. The transmission belt 4 is a circular conveying structure, with one side input and one side output.

[0032] The sliding plate 5 is used to adjust the horizontal position of the clamping mechanism 3. One end of the sliding plate 5 passes through the first partition...

specific Embodiment approach 2

[0037] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as figure 1 and figure 2 As shown, the upper layer 1 is in the shape of a rectangular box with rounded corners, an upper cover 11 is installed in the middle of the top surface of the upper layer 1, a first partition plate 12 and a second partition plate 13 are fixed inside the upper layer 1, and a connecting plate is opened on the bottom plate of the upper layer 1. Groove 14, fan 15 is embedded on the second partition 13, with the second partition 13 as the dividing line, the two sides of the second partition 13 are respectively the discharge side and the discharge side, and the two loam cakes 11 are covered separately. On the discharge side and the discharge side, the upper and lower materials do not interfere with each other, and the fan 15 is used to dry the cleaned lenses.

specific Embodiment approach 3

[0038] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode two, such as figure 2 As shown, the first partition 12 and the rounded corner near the first partition 12 form a semicircular groove, and a sliding mechanism 52 is installed in the semicircular groove formed by the first partition 12 on the left side, and the second partition 13 is located at On the line connecting the centers of the two semicircles, the length of the second partition 13 is less than the distance between the first partitions 12, the second partition 13 is connected to the first partition 12 on the right side, and the communication groove 14 is located at the first partition on the left side. Between the partition 12 and the second partition 13, a sliding mechanism 52 and a driving mechanism of the transmission belt 4 are installed in the semicircular groove, which cooperate with the top plate of the upper layer 1 to form a closed mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com