Airtight cabin-penetrating optical fiber connector

An optical fiber connector and piercing technology, which is applied in the field of connectors, can solve the problems of limited flexibility, the connector does not have a plug-in function, and the mechanical properties of the connector are limited. location-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with specific embodiments.

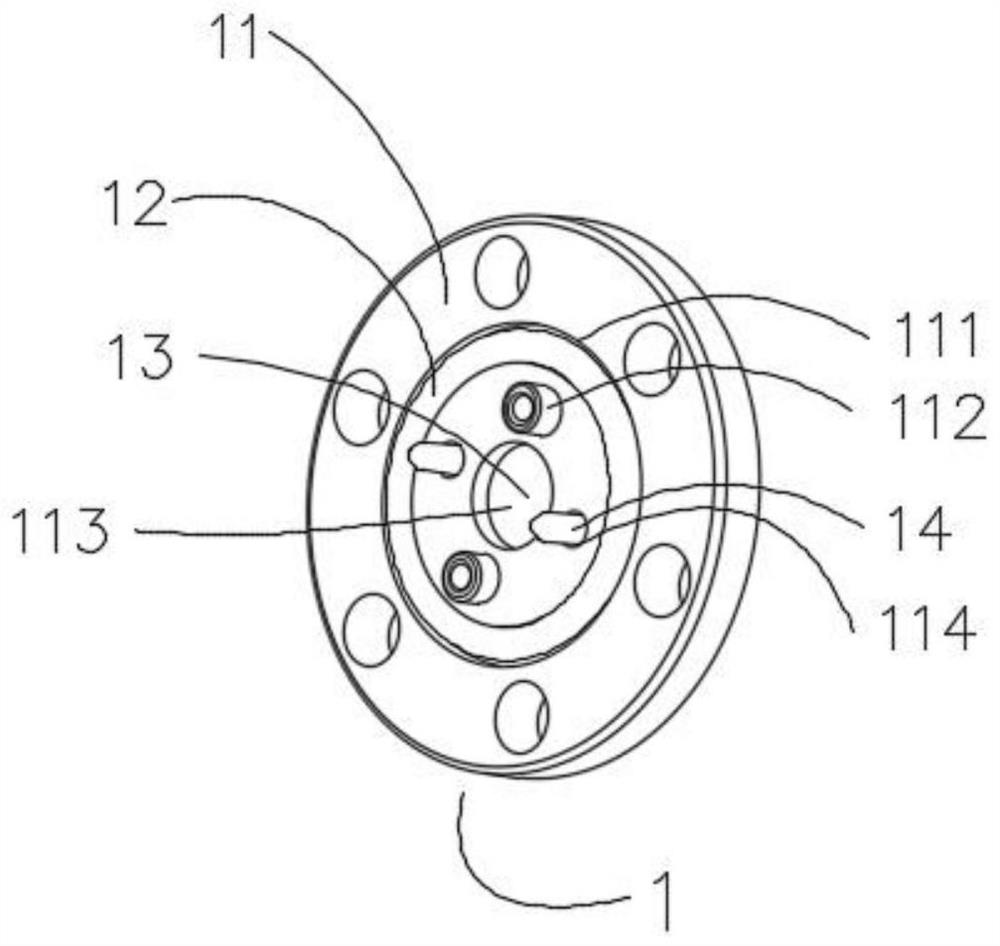

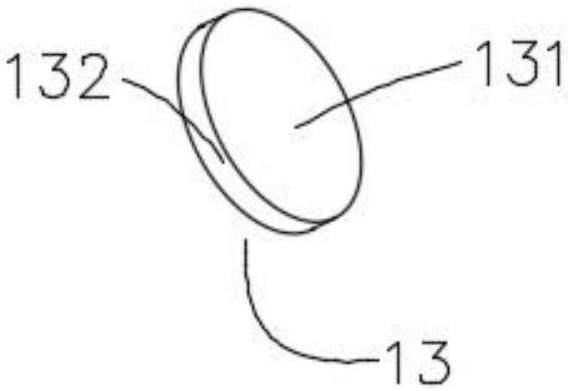

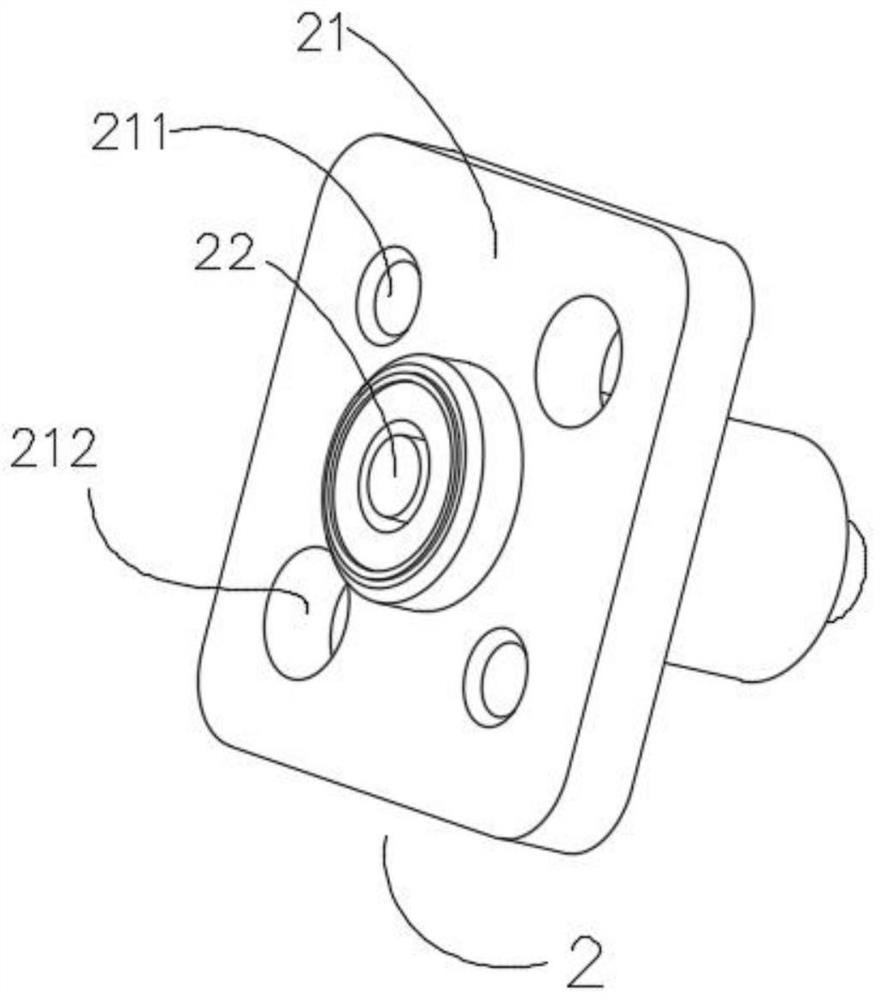

[0029] refer to Figure 1-5 , an airtight cabin-penetrating optical fiber connector, comprising a transfer socket 1 and two plugs 2, the transfer socket 1 includes a socket housing 11, the middle part of the socket housing 11 is provided with a central through hole 113, and the central through hole 113 is fixedly connected to the optical window sheet 13, the inner wall of the central through hole 113 is provided with a gold-plated layer, and the circumferential surface 132 of the optical window sheet 13 is provided with a gold-plated layer; the gold-plated layer is set to be more conducive to welding, and the central through hole 113 and the optical window sheet 13 The fixed connection by welding can meet the airtightness requirements.

[0030] Positioning through holes 114 are arranged symmetrically on both sides of the central through hole 113 on the socket housing 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com