Mining color sorter with size screening control system

A technology of control system and color sorter, which is applied in the field of color sorter, can solve the problems of sorting error, large difference in throwing position, inability to classify ore size, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

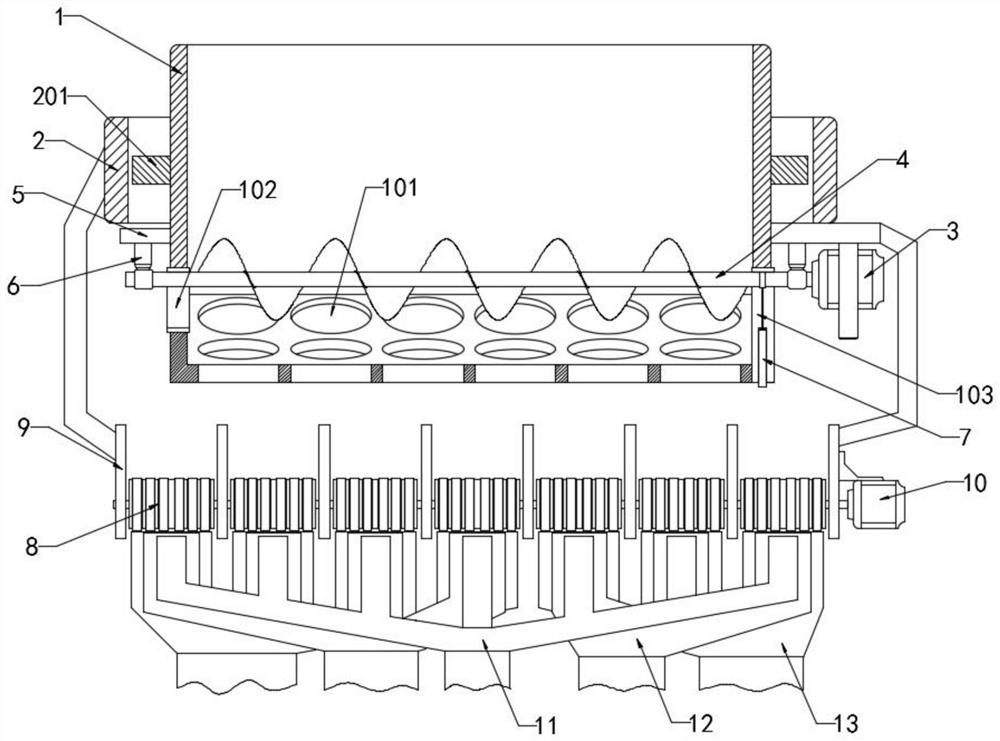

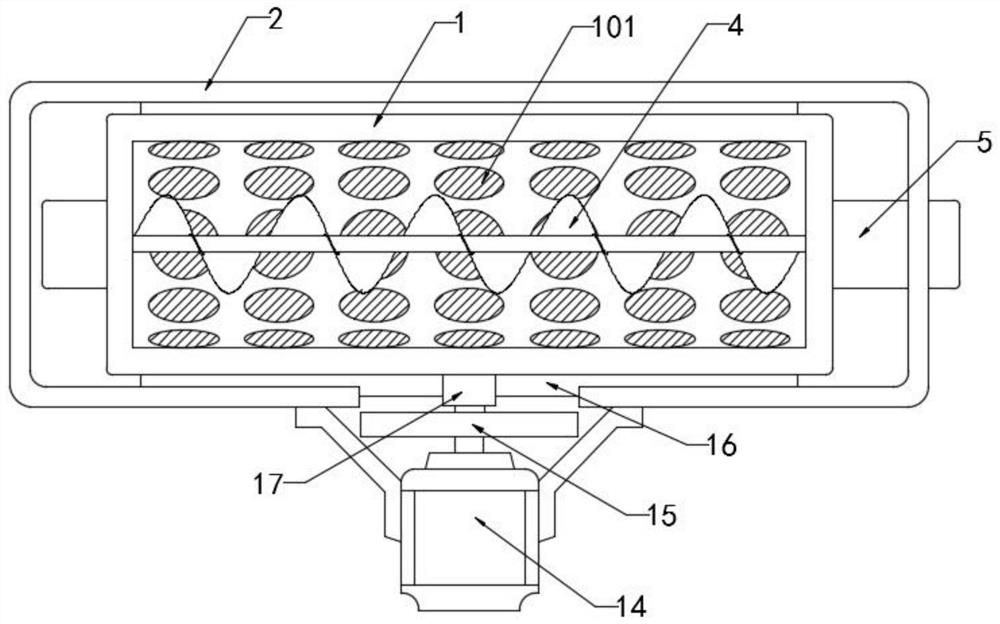

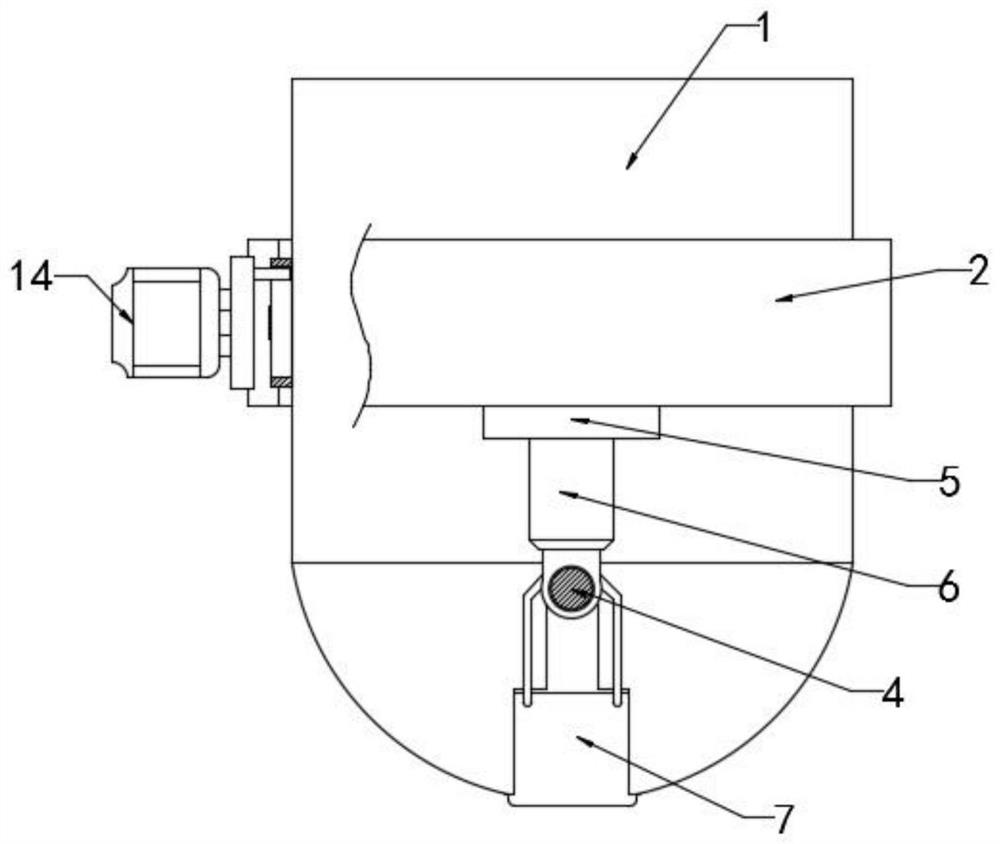

[0031] The following is attached Figure 1-6 The present invention is described in further detail.

[0032] The embodiment of the invention discloses a mine color sorter with a size screening control system. refer to Figure 1-3 , a mining color sorter with a size screening control system, including a hopper 1, the bottom of the hopper 1 is provided with sieve holes 101, the side view of the hopper 1 has a U-shaped structure, and the sieve holes 101 are evenly distributed on the bottom of the hopper 1 On the arc-shaped surface, a fixed ring 2 is set on the outside of the top of the hopper 1, and the centerline position bolt on one side of the fixed ring 2 is fixedly connected with a third drive motor 14, and the third drive motor 14 is transmitted between the reciprocating mechanism and the hopper 1. Connected, the reciprocating mechanism includes a wheel disc 15, a slide bar 16 and a straight notch ring 17, the wheel disc 15 is sleeved on the output shaft of the third drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com