Material stirrer and large-volume hopper

A mixer and a generous amount of technology, applied in chemical instruments and methods, cement mixing devices, unloading devices, etc., can solve problems such as affecting the normal use of equipment, difficult to clean concrete solidification, and unsmooth discharge, to avoid difficult cleaning. problems, smooth discharge, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

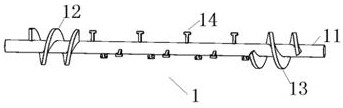

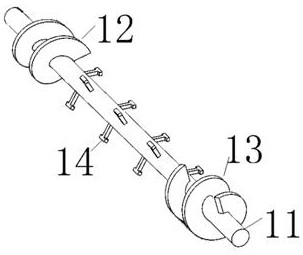

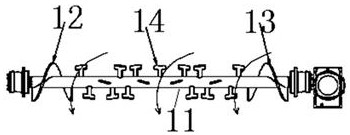

[0036] Combine below Figure 1-9 Specifically explain the intelligent garbage sorting station, such as Figure 1-2 Shown is a material agitator. The material agitator 1 includes a stirring shaft 11 , a left-handed blade 12 , a right-handed blade 13 and a plurality of stirring teeth 14 .

[0037] Such as Figure 1-2 As shown, the left-handed blade 12 and the right-handed blade 13 are respectively installed on the stirring shaft 11; when the stirring shaft 11 is installed in the hopper, the left-handed blade 12 and the right-handed blade 13 are respectively located at both ends of the stirring shaft 11 in the hopper.

[0038] Such as Figure 1-2 As shown, a plurality of stirring teeth 14 are located between the left-handed blade 12 and the right-handed blade 13 , and are balancedly installed on the outer periphery of the stirring shaft 11 .

[0039] Such as Figure 1-2 As shown, the stirring teeth 14 are T-shaped. Stirring teeth 14 are T-shaped, including stirring rod 1 and...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is: as image 3 As shown, the angle between the length direction of the stirring tooth 14 and the axis of the stirring shaft 11 is an acute angle (preferably 5-30°), and the angle between the length direction of the stirring rod 2 and the axis of the stirring shaft 11 in this embodiment is 15°.

Embodiment 3

[0053] The difference between the present embodiment and the first embodiment is that: the stirring teeth 14 are in the shape of straight plates; the number of discharge doors 3 is fifteen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com