Device and method for detecting sealing performance of transformer expansion tank capsule

A technology of leak detection and transformer oil, which is applied in the direction of fluid tightness test, measuring device, liquid tightness measurement using liquid/vacuum degree, etc. It can solve problems such as inability to maintain pressure for a long time, inaccurate detection, etc. To achieve the effect of convenient air tightness inspection, convenient disassembly and assembly, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

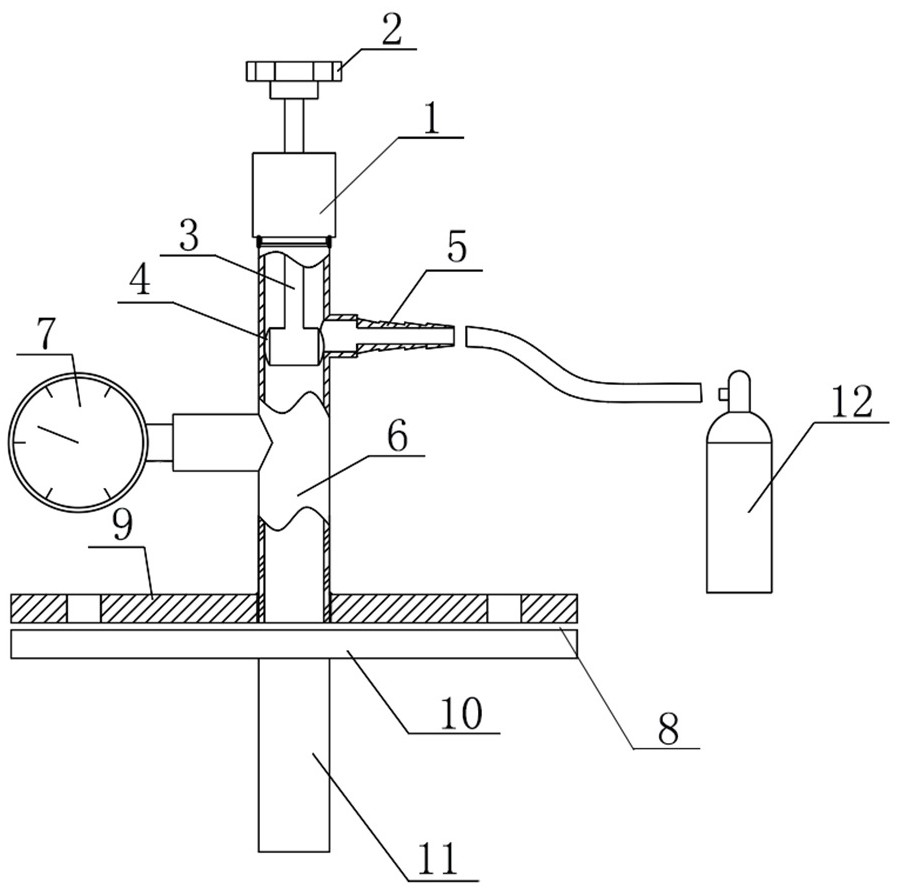

[0032] Such as figure 1 As shown, in this embodiment, a transformer oil conservator capsule leak detection device mainly includes a detection device body 1, a valve 2, a transmission rod 3, a seal 4, an air supply interface 5, an internal pipeline 6, and a pressure gauge 7 Connect the flange 8 with the transformer respirator.

[0033] In this embodiment, the top of the detection device body 1 is provided with a valve 2; the valve 2 is connected to the transmission rod 3; the lower end of the transmission rod 3 is connected to the seal 4; one side of the seal 4 is provided with an air supply interface 5; The middle part of the detection device body 1; the middle part of the detection device body 1 is provided with an internal pipe 6; the side wall of the internal pipe 6 is connected to the pressure gauge 7; the lower end of the detection device body 1 is provided with a transformer respirator connection flange 8.

[0034] In this embodiment, the connecting flange 8 of the pres...

Embodiment 2

[0050] In this embodiment, the top of the detection device body 1 is provided with a valve 2; the valve 2 is connected to the transmission rod 3; the lower end of the transmission rod 3 is connected to the seal 4; one side of the seal 4 is provided with an air supply interface 5; The middle part of the detection device body 1; the middle part of the detection device body 1 is provided with an internal pipe 6; the side wall of the internal pipe 6 is connected to the pressure gauge 7; the lower end of the detection device body 1 is provided with a transformer respirator connection flange 8.

[0051] In this embodiment, the connecting flange 8 of the pressurizer respirator is divided into an upper connecting flange 9 and a lower connecting flange 10 .

[0052] In this embodiment, the upper connecting flange 9 is connected to the lower connecting flange 10 .

[0053] In this embodiment, both the upper connecting flange 9 and the lower connecting flange 10 are connected to the shaf...

Embodiment 3

[0067] In this embodiment, the top of the detection device body 1 is provided with a valve 2; the valve 2 is connected to the transmission rod 3; the lower end of the transmission rod 3 is connected to the seal 4; one side of the seal 4 is provided with an air supply interface 5; The middle part of the detection device body 1; the middle part of the detection device body 1 is provided with an internal pipe 6; the side wall of the internal pipe 6 is connected to the pressure gauge 7; the lower end of the detection device body 1 is provided with a transformer respirator connection flange 8.

[0068] In this embodiment, the connecting flange 8 of the pressurizer respirator is divided into an upper connecting flange 9 and a lower connecting flange 10 .

[0069] In this embodiment, the upper connecting flange 9 and the lower connecting flange 10 are tightly connected.

[0070] In this embodiment, both the upper connecting flange 9 and the lower connecting flange 10 are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com