Compact power distribution box

A distribution box, compact technology, applied in the direction of substation/power distribution device shell, electrical components, substation/switch layout details, etc., can solve problems such as equipment failure, temperature rise of distribution box, gas accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] as attached figure 1 to attach Figure 7 Shown:

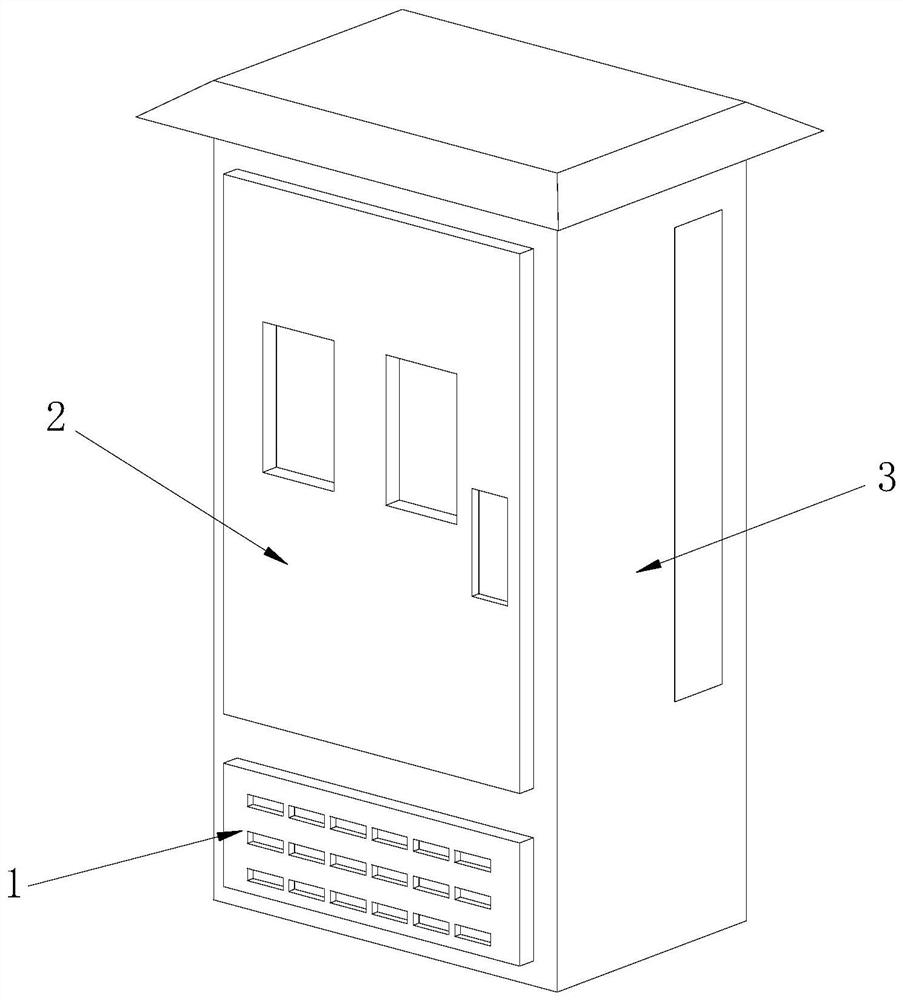

[0029] The present invention provides a compact distribution box, the structure of which includes: an exhaust plate 1, a door leaf 2, and a box body 3, the rear end of the exhaust plate 1 is embedded in the inner side of the box body 1, and the door leaf 2 is hinged Installed in the front of the box body 3.

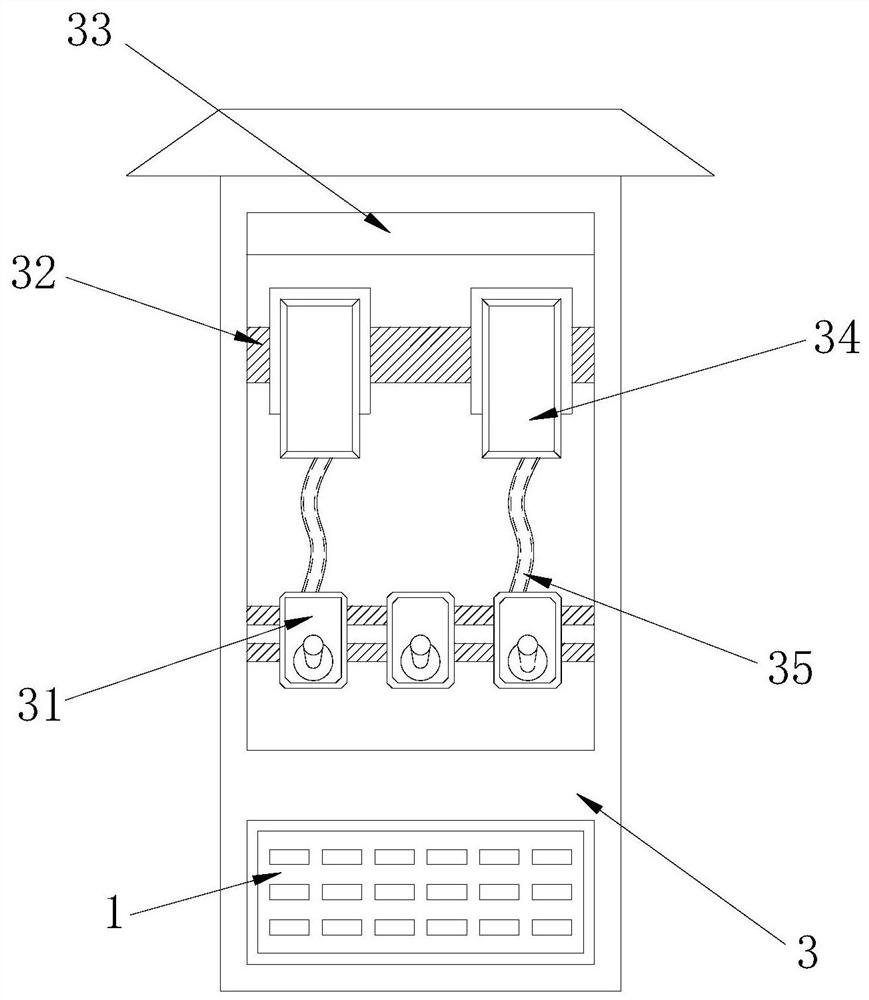

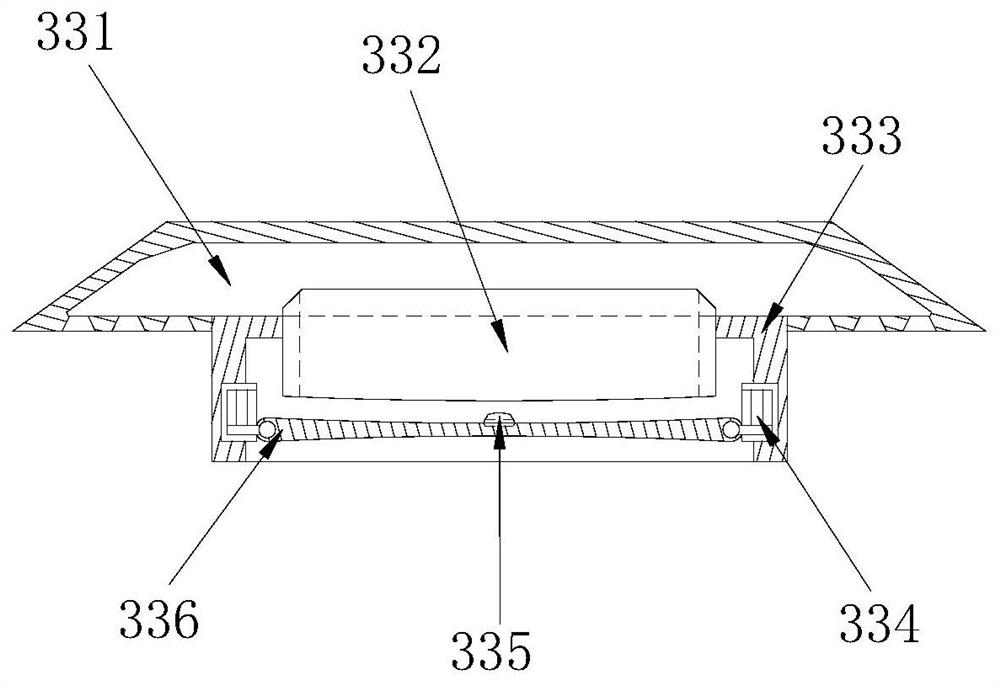

[0030] Wherein, the box body 3 includes a protective element 31, a mounting plate 32, a telescopic device 33, a display 34, and a connecting wire 35. The rear end surface of the protective element 31 is bolted to the front end surface of the mounting plate 32, and the mounting plate 32 and the box body 3 are integrated structures, the lower end of the telescopic device 33 is embedded in the inner side of the box body 3, the display 34 is detachably installed in front of the mounting plate 32, and the front surface of the display 34 is embedded with the door leaf 2 The connecting wire 35 is installed between the ...

Embodiment 2

[0039] as attached Figure 7 As shown: the moving mechanism 223 includes a flexible plate a1, a buffer mechanism a2, a support rod a3, a connecting rod a4, an exhaust port a5, and a U-shaped groove a6. The flexible plate a1 is embedded in the inner side of the U-shaped groove a6, and The upper end surface of the flexible plate a1 is fixedly connected to the lower end surface of the connecting rod a4, the lower end surface of the buffer mechanism a2 is embedded and connected to the upper end surface of the connecting rod a4, and the support rod a3 is installed on both sides of the connecting rod a4 , the exhaust hole a5 is installed between the U-shaped grooves a6, the flexible plate a1 is made of spring steel, and the flexible plate a1 has elastic properties, so after the connecting rod a4 moves, it can pass through the elastic properties of the flexible plate a1 Drive the connecting rod a4 back to its original state.

[0040] as attached Figure 8 to attach Figure 9 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com