Rapid grinding equipment for inner ring of birdcage frame

A fast, inner-ring technology, applied in grinding/polishing equipment, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve problems such as low productivity, unsafe use, uneven grinding, etc., and achieve increased The effect of high productivity, simple structure and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

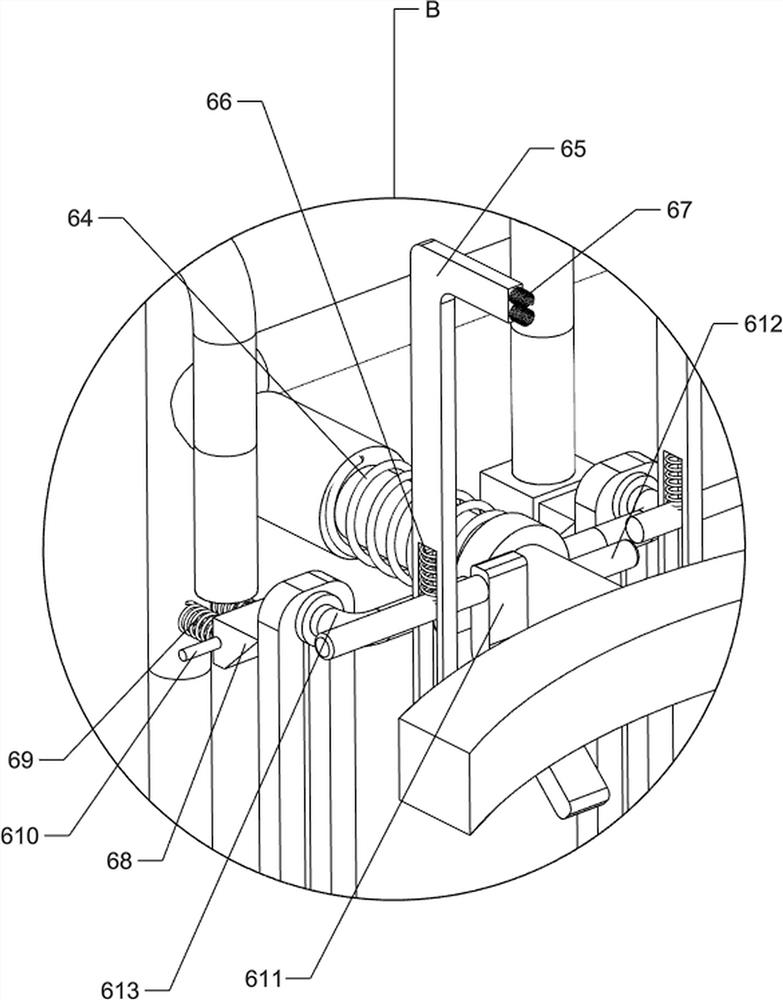

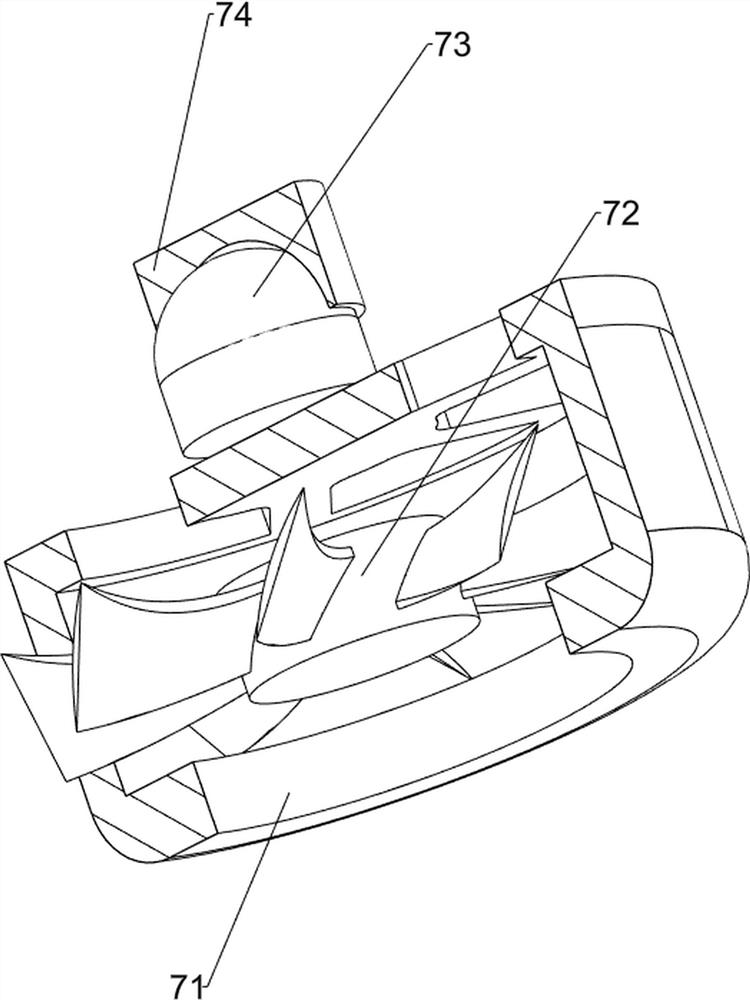

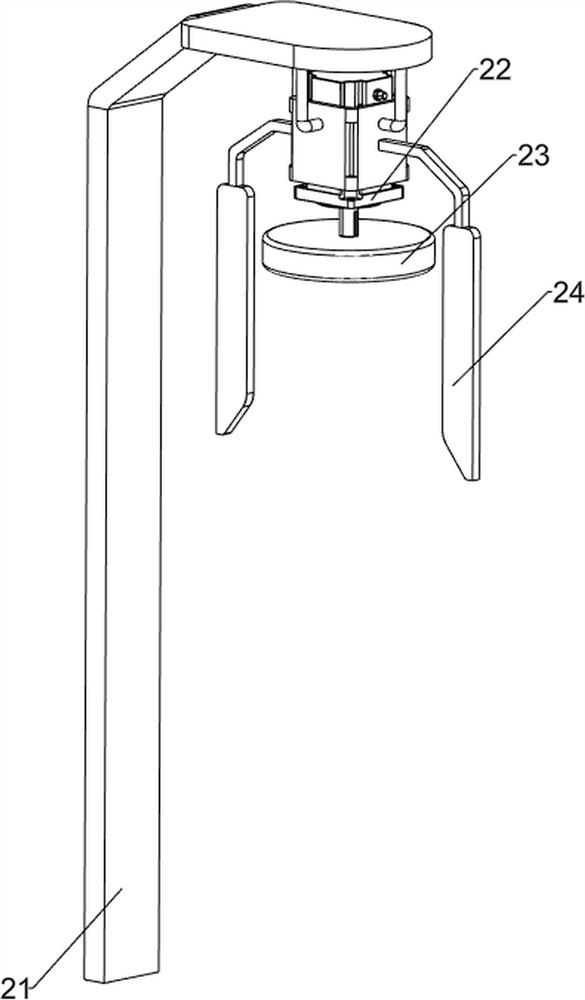

[0028] A kind of rapid grinding equipment for the inner ring of a birdcage frame, such as Figure 1-Figure 5 As shown, it includes a base 1, a grinding mechanism 2, a clamping mechanism 3 and a placement mechanism 4, a grinding mechanism 2 is provided on the rear side of the top of the base 1, a clamping mechanism 3 is provided on the grinding mechanism 2, and a placement mechanism is provided on the top of the base 1 4.

[0029] First, people place the inner circle of the birdcage frame on the placement mechanism 4, lift the placement mechanism 4 upwards, start the grinding mechanism 2 to cooperate with the clamping mechanism 3, and polish the inner circle of the birdcage frame on the placement mechanism 4, and put it down after the polishing is completed. Placement mechanism 4, the birdcage frame inner ring that makes grinding complete breaks away from grinding mechanism 2, is convenient for people to take out, reaches the effect that structure is simple and easy to operate ...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 6-Figure 9 As shown, it also includes a blanking assembly 5, and the blanking assembly 5 includes a third support rod 51, a charging frame 52, a pushing plate 53, a first rack 54, a first gear 55, a ratchet gear 56, a second Fixed block 57 and the 3rd spring 58, base 1 top left side is provided with the 3rd support bar 51 symmetrically front and back, is provided with charging frame 52 between the 3rd support bar 51, and charging frame 52 bottom left sliding type is provided with push-button. Feeding plate 53, the top of pushing plate 53 is symmetrically provided with first rack 54 front and back, and the lower left side of charging frame 52 is provided with second fixed block 57 symmetrically front and back, and the second fixed block 57 is provided with ratchet gear 56 in a rotating manner. A first gear 55 is arranged inside each ratchet gear 56 , and the first gear 55 meshes with the first rack 54 , and a third spring 58 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com